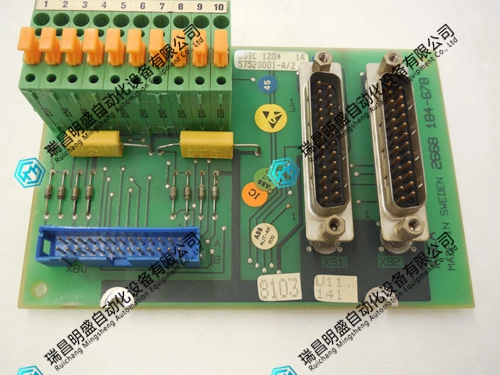

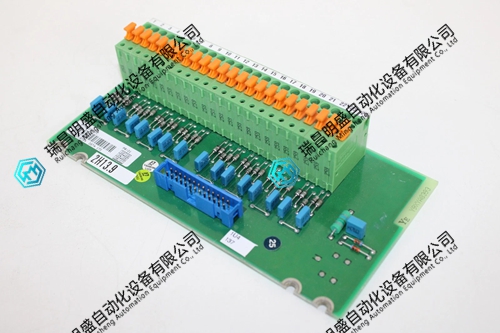

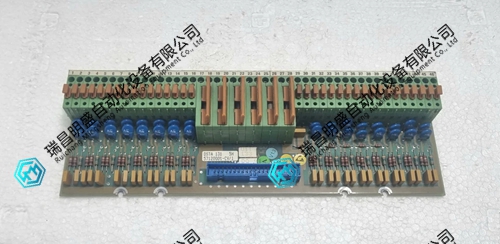

1.产 品 资 料 介 绍:

本板为ABB工业级通信板,核心用于工控系统模块间数据交互与链路衔接,支持多类串行接口及协议适配,以下为10条核心使用要点,保障通信稳定及设备安全。

1. 核对型号为5750001-ER DSTC190,确认外观完好、接口无变形氧化,确保与对应工控系统及上下游模块兼容,记录序列号便于溯源。

2. 全程做好静电防护,佩戴接地手环操作,存放搬运用防静电袋,远离强电磁干扰、潮湿及振动环境,保护板卡芯片与通信接口。

3. 安装前断开总电源,待回路电容放电完毕,清理安装槽及板卡接口灰尘,采用配套套件固定,预留散热与操作空间,布线规整有序。

4. 按标识区分信号、电源接口精准对接,选用屏蔽线缆,与动力电缆分开布线,紧固端子防止虚接,杜绝错接引发板卡损坏或通信中断。

5. 确认供电电压符合额定要求,接地可靠避免电位差干扰,保障RS-232/RS-485等接口信号传输稳定性。

6. 调试时核查协议适配状态与通信参数匹配度,测试数据传输速率及精度,记录核心运行参数,确保符合系统控制需求。

7. 启用访问权限保护,防范非法改写通信配置,搭配软硬件防护机制,保障链路数据与控制逻辑安全。

8. 运行中监控板卡状态与自诊断报警信息,避免过载接入设备,实时关注散热情况,防止芯片过热或接口故障。

9. 定期断电维护,清理板卡灰尘与接口氧化层,检查线缆紧固性,排查接触不良、电容鼓包等隐患。

10. 故障时先断电排查链路、接口及兼容性问题,通过自诊断功能定位故障点,疑难问题联系专业人员或厂家售后处理。

遵循以上要点,可充分发挥DSTC190通信板性能,保障工控系统链路通畅与稳定运行,适配电力、环保、制造业等工业自动化场景。

5750001-ER DSTC190通信板 英文资料:

This board is an ABB industrial grade communication board, which is used for data exchange and link connection between industrial control system modules. It supports multiple types of serial interfaces and protocol adaptation. The following are 10 key usage points to ensure communication stability and equipment security.

1. Verify that the model is 5750001-ER DSTC190, confirm that the appearance is intact, the interface is not deformed or oxidized, ensure compatibility with the corresponding industrial control system and upstream and downstream modules, and record the serial number for traceability.

2. Carry out electrostatic protection throughout the process, wear a grounding wristband for operation, store and transport anti-static bags, stay away from strong electromagnetic interference, humidity, and vibration environments, and protect the board chips and communication interfaces.

3. Disconnect the main power supply before installation, wait for the circuit capacitor to discharge completely, clean the installation slot and board interface dust, fix them with matching kits, reserve space for heat dissipation and operation, and ensure that the wiring is neat and orderly.

4. Distinguish the signal and power interfaces accurately according to the identification, select shielded cables, separate them from the power cables, tighten the terminals to prevent virtual connections, and prevent misconnection from causing damage to the board or communication interruption.

5. Confirm that the power supply voltage meets the rated requirements, the grounding is reliable to avoid potential difference interference, and ensure the stability of interface signal transmission such as RS-232/RS-485.

6. During debugging, verify the compatibility between protocol adaptation status and communication parameters, test data transmission rate and accuracy, record core operating parameters, and ensure compliance with system control requirements.

7. Enable access permission protection to prevent illegal rewriting of communication configurations, and combine software and hardware protection mechanisms to ensure the security of link data and control logic.

8. During operation, monitor the status of the board and self diagnostic alarm information to avoid overloading the device, monitor the heat dissipation situation in real time, and prevent chip overheating or interface failures.

9. Regular power-off maintenance, cleaning of board dust and interface oxide layer, checking cable tightness, and troubleshooting for potential hazards such as poor contact and capacitor bulges.

10. When there is a malfunction, first disconnect the power and troubleshoot the link, interface, and compatibility issues. Use the self diagnostic function to locate the fault point, and contact professional personnel or manufacturer after-sales service for difficult problems.

Following the above points can fully leverage the performance of the DSTC190 communication board, ensure smooth and stable operation of industrial control system links, and adapt to industrial automation scenarios such as power, environmental protection, and manufacturing.

产品视频

3.其他产品

Eaton 8937-HN数字输出模块

Schneider 140CPU67160C处理器模块

Ge IS200EPSMG1ABB电源模块

4.其他英文产品

MTS TBF120/7R servo amplifier

METSO D201925 Positioner Module

CI541V1 3BSE014666R1 Analog Input/Output Module

| 745-W2-P5-G5-HI-A-E-H | 8030-RIM-101 | X-FTA 009 02L |

| 745-W2-P5-G5-HI-A-E | 8030-R1M-185A | X-FTA 008 02L |

| 745-W2-P5-G5-HI-A | 8030-PV-28 | X-FTA 007 02L |

| 745-W2-P5-G5-HI | 8030-PS-70 | X-FTA 006 02L |

| 745-W2-P1-G1-LO-E | 8030-PS-51 | X-FTA 006 01L |

| 745-W2-P1-G1-HI-T-H | 8030-PS-41 | X-FTA 005 02L |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218