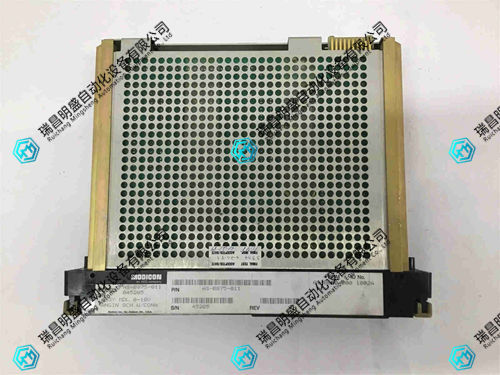

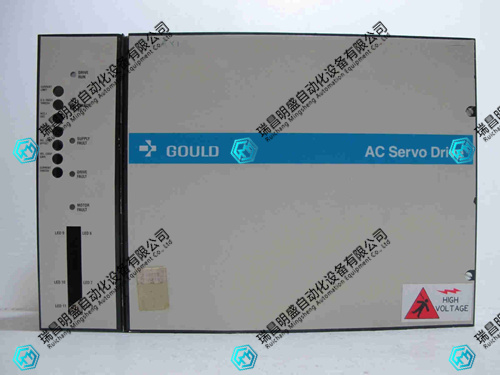

AEG MODICON A332-03交流电伺服驱动器

1.产 品 资 料 介 绍:

- 小型印刷设备控制:调节印刷辊速与走纸定位联动,精准同步印版与物料,保障印刷图案无偏移

- 实验室反应装置:控制小型搅拌器、温控器与试剂加注,稳定执行实验流程,提升数据重复性

- 智能灌溉系统:联动土壤湿度传感器与灌溉阀自动启停,按需供水,兼顾节水与作物生长需求

- 小型注塑辅机控制:调节上料机、干燥机运行逻辑,保障原料供给稳定,适配注塑生产节奏

- 快递小型分拣台:扫码触发后控制导向机构动作,快速分流货物,提升小批量分拣效率

- 木工小型加工机:协调裁板、打磨工位工序,精准控制加工动作时序,保障工件尺寸一致性

- 小型空压机站:监测气压并自动控制机组启停,维持稳定供气,减少无效能耗

- 医疗耗材包装机:对接封口、计数设备联动,保障包装密封达标,同时精准统计产量

- 小型涂装设备:同步控制喷枪启停与输送台速度,确保涂层均匀,提升涂装合格率

- 饲料小型配料机:精准控制多原料配比与混合时间,保障饲料营养均衡,适配小型养殖场需求

- 光伏组件串焊辅机:控制焊带送料与定位机构,保障焊带对齐精度,助力提升组件焊接质量

- 小型冷库温控:联动制冷机组与通风设备,稳定维持库内恒温,保障存储货物新鲜度

- 电子元件测试台:控制测试探针动作与数据采集联动,高效完成元件性能检测,简化测试流程

- 小型除尘设备:监测粉尘浓度并控制风机启停,快速净化空气,改善车间作业环境

- 玩具组装生产线:协调装配工位动作与计数统计,保障组装流程顺畅,同步记录生产数据

AEG MODICON A332-03交流电伺服驱动器 英文资料:

Control of small printing equipment: adjust the speed of the printing roller and link it with the positioning of the paper feed, accurately synchronize the printing plate and material, and ensure that the printed pattern is not offset

Laboratory reaction equipment: Control small stirrers, temperature controllers, and reagent dispensing to ensure stable execution of experimental procedures and improve data reproducibility

Intelligent irrigation system: linked with soil moisture sensors and irrigation valves to automatically start and stop, providing on-demand water supply, balancing water conservation and crop growth needs

Small injection molding auxiliary machine control: adjust the operating logic of the feeding machine and dryer to ensure stable raw material supply and adapt to the pace of injection molding production

Express small sorting table: after scanning the code, it controls the action of the guiding mechanism to quickly divert goods and improve the efficiency of small batch sorting

Woodworking small processing machine: Coordinate the cutting and polishing station processes, accurately control the timing of processing actions, and ensure the consistency of workpiece dimensions

Small air compressor station: monitors air pressure and automatically controls unit start stop to maintain stable gas supply and reduce ineffective energy consumption

Medical consumables packaging machine: linked with sealing and counting equipment to ensure packaging sealing meets standards, while accurately counting production

Small coating equipment: synchronized control of spray gun start stop and conveyor speed to ensure uniform coating and improve coating qualification rate

Small feed batching machine: precise control of multiple raw material ratios and mixing times to ensure balanced feed nutrition and meet the needs of small farms

Photovoltaic module string welding auxiliary machine: controls the feeding and positioning mechanism of the welding strip, ensures the alignment accuracy of the welding strip, and helps improve the welding quality of the components

Small cold storage temperature control: linked refrigeration unit and ventilation equipment to maintain a stable temperature inside the warehouse, ensuring the freshness of stored goods

Electronic component testing bench: controls the linkage between test probe actions and data acquisition, efficiently completes component performance testing, and simplifies the testing process

Small dust removal equipment: Monitor dust concentration and control fan start stop, quickly purify air, and improve workshop working environment

Toy assembly production line: Coordinate assembly station actions and counting statistics to ensure smooth assembly process and synchronized recording of production data

AEG MODICON A332-03交流电伺服驱动器 产品展示

产品视频

3.其他产品

Allen-Bradley 1756-IF8模拟输入模块

Allen Bradley 1756-L61 B控制器

Allen Bradley 1756-L61A通讯模块

4.其他英文产品

IS200SPIDG1ABA combustion engine card

GE IS220PPRFH1B 336A5026ADP2 power supply module

P0916PH P0916AL Terminal module

| IC3600LSRB1A | 531X184IPTAFG1 | IC3600EPSC1B |

| IC3600LSRB1 | 531X184IPTAEG1 | IC3600EPSC1 |

| IC3600LSRA1 | 531X184IPTADG1 | IC3600EPSB1C |

| IC3600LSOC1B | 531X182IFGAJG1 | IC3600EPSB1B |

| IC3600LSOC1 | 531X182IFGAHG1 | IC3600EPSB1A |

| IC3600LSFD1B1B | 531X182IFGAEG1 | IC3600EPSB1 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218