SANYO DENKI PROGRAMMABLE伺服驱动模块

1.产 品 资 料 介 绍:

- 核心可编程特性:Sanyo Denki PROGRAMMABLE 伺服驱动模块支持自定义编程,可通过专用软件编写运动控制逻辑,无需额外 PLC 即可实现单轴 / 多轴协同控制,简化系统架构。

- 多运动模式集成:内置位置控制、速度控制、转矩控制等多种基础模式,且支持模式间无缝切换,通过编程可灵活适配复杂运动场景,如凸轮同步、电子齿轮传动。

- 功能扩展性强:预留扩展接口,可外接传感器、执行器等外设,通过编程实现外设与驱动模块的联动控制,满足个性化自动化需求,如物料检测 + 精准定位的联动流程。

- 工业协议兼容性:支持 Profinet、EtherCAT 等主流工业总线,编程时可轻松实现与上位机、MES 系统的数据交互,便于工厂自动化的集中管控与数据追溯。

- 调试便捷性:配备可视化编程界面与在线调试功能,可实时监控程序运行状态,快速排查逻辑错误,缩短调试周期,降低技术人员操作门槛。

- 高精度控制能力:结合可编程算法优化,可实现微米级定位精度与毫秒级响应速度,适配精密制造场景,如半导体晶圆搬运、电子元件精密组装。

- 故障自诊断编程:支持自定义故障检测逻辑,可通过编程设置特定工况下的报警阈值与处理方案,如过载后的降速保护、异常信号的自动复位,提升系统稳定性。

- 多轴协同编程:单模块可支持多轴控制,通过编程实现轴间同步、插补运动(如直线插补、圆弧插补),适配需要复杂轨迹控制的设备,如数控雕刻机、机器人手臂。

- 环境适应性强:采用工业级防护设计,配合可编程的温度、湿度补偿算法,能在 - 10℃~50℃温度范围及多粉尘、振动场景稳定运行,适配恶劣工业环境。

- 节能优化编程:支持通过编程设置能耗管理策略,如闲置时段自动进入低功耗模式、负载波动时动态调整输出功率,兼顾控制性能与能源效率,降低长期运行成本。

SANYO DENKI PROGRAMMABLE伺服驱动模块 英文资料:

Core programmable feature: Sanyo Denki PROGRAMMABLE servo drive module supports custom programming and can write motion control logic through dedicated software. It can achieve single axis/multi axis collaborative control without the need for an additional PLC, simplifying the system architecture.

Multi motion mode integration: Built in position control, speed control, torque control and other basic modes, and supports seamless switching between modes. Through programming, it can flexibly adapt to complex motion scenarios, such as cam synchronization and electronic gear transmission.

Strong functional scalability: Reserved expansion interfaces can be used to connect external devices such as sensors and actuators. Through programming, the linkage control between external devices and driver modules can be achieved to meet personalized automation needs, such as the linkage process of material detection and precise positioning.

Industrial protocol compatibility: Supports mainstream industrial buses such as Profinet and EtherCAT, and can easily achieve data exchange with the upper computer and MES system during programming, facilitating centralized control and data tracing of factory automation.

Debugging convenience: Equipped with a visual programming interface and online debugging function, it can monitor the running status of the program in real time, quickly troubleshoot logical errors, shorten the debugging cycle, and reduce the operating threshold for technical personnel.

High precision control capability: Combined with programmable algorithm optimization, it can achieve micrometer level positioning accuracy and millisecond level response speed, suitable for precision manufacturing scenarios such as semiconductor wafer handling and electronic component precision assembly.

Fault self diagnosis programming: supports custom fault detection logic, and can set alarm thresholds and processing solutions for specific operating conditions through programming, such as speed reduction protection after overload and automatic reset of abnormal signals, to improve system stability.

Multi axis collaborative programming: A single module can support multi axis control, achieving inter axis synchronization and interpolation motion (such as linear interpolation and arc interpolation) through programming, and adapting to equipment that requires complex trajectory control, such as CNC engraving machines and robot arms.

Strong environmental adaptability: Adopting industrial grade protection design, combined with programmable temperature and humidity compensation algorithms, it can operate stably in the temperature range of -10 ℃~50 ℃ and in dusty and vibration scenarios, adapting to harsh industrial environments.

Energy saving optimization programming: supports setting energy management strategies through programming, such as automatically entering low-power mode during idle periods, dynamically adjusting output power during load fluctuations, balancing control performance and energy efficiency, and reducing long-term operating costs.

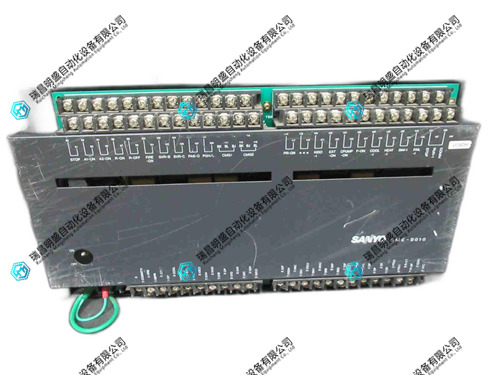

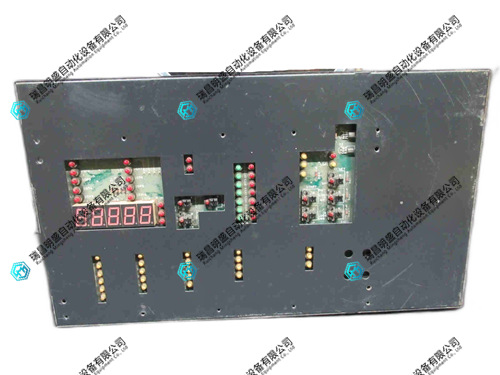

SANYO DENKI PROGRAMMABLE伺服驱动模块 产品展示

产品视频

3.其他产品

DELTA TAU ACC-68E 输入输出模块

IMRIO02 远程 I/O 模块

57310001-PK 可编程逻辑控制器

4.其他英文产品

NI PXLE-5774 Embedded Controller

MKS SPECTRUM11002-00 RF Generator

COMDEL CDX2000-0190-54753 Dual RF Generator

| PMA42Q-10100-00 | AMAT 0100-09020 | PFTL101AER |

| PMA42Q-01100-00 | AMAT 0100-90221 | PFTL201CE |

| PMA42P-11100-00 | AMAT 0100-77034 | PFTL201DE |

| PMA42P-10100-00 | AMAT 0100-00042 | PFTL101BE-2.0KN 3BSE004214R1 2.0KN |

| PMA42P-01100-00 | AMAT 0100-00005 | PFTL101AER-1.0KN 3BSE023011R1 1.0KN |

| PMA42P-00100-00 | AMAT 0100-02706 | PFEA112-IP65 3BSE050091R65 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218