1.产 品 资 料 介 绍:

BRC-200控制器板产品应用领域

1. ABB DCS系统升级:适配Harmony/INFI 90系统,替代老旧控制器,提升远程I/O链路通信速度与兼容性。

2. 石油化工过程控制:依托光纤通信,在易燃易爆工况下实现远程设备管控与工艺参数闭环调节。

3. 电力电站运维管控:部署于电厂中控,通过冗余设计保障机组运行数据传输与指令下发的稳定性。

4. 冶金钢铁流程调控:适配高温复杂环境,联动远程I/O模块,精准执行高炉、轧钢工艺调控指令。

5. 水处理工艺控制:对接水质监测传感器,通过光纤链路实现污水处理环节的远程智能管控。

6. 天然气开采管控:符合防爆工况要求,构建冗余通信网络,保障开采设备安全稳定运行。

7. 化工园区集中管控:搭建分布式控制架构,实现多装置协同运作与故障快速切换自愈。

8. 制药行业合规控制:适配洁净生产环境,保障工艺参数可追溯,满足行业合规管控需求。

9. 水泥生产流程控制:耐受粉尘高温工况,联动窑炉设备,实现生产全流程自动化调控。

10. 造纸行业工艺管控:对接生产线远程I/O,精准调节车速、湿度等参数,提升产品质量稳定性。

11. 能源化工冗余控制:依托双路光纤链路,构建主备冗余系统,避免生产环节意外停机。

12. 氧化铝生产管控:适配腐蚀性工况,实现焙烧、溶解等工序的远程设备联动与参数优化。

13. 工业旧系统改造:兼容原有光纤电缆与机架,低成本完成老旧控制器的升级替换。

14. 精细化工过程控制:精准控制反应釜温度、压力参数,保障小批量多批次生产稳定性。

15. 煤化工业态管控:应对高粉尘、高湿度环境,实现采煤、焦化环节的远程智能调控。

该控制器板核心优势在于适配ABB Harmony系统、支持光纤点对点通信与冗余架构,具备快速故障切换、固件闪存升级特性,兼容原有设备与光纤链路,适配化工、电力等复杂防爆及高温工况的分布式控制需求。

BRC-200 Controller Board Product Application Fields

1. ABB DCS system upgrade: compatible with Harmony/INFI 90 system, replacing old controllers, improving remote I/O link communication speed and compatibility.

2. Petrochemical process control: relying on fiber optic communication, remote equipment control and closed-loop adjustment of process parameters can be achieved under flammable and explosive conditions.

3. Power plant operation and maintenance control: deployed in the central control of the power plant, ensuring the stability of unit operation data transmission and instruction issuance through redundant design.

4. Metallurgical steel process control: adapted to high temperature and complex environments, linked with remote I/O modules, accurately executing blast furnace and steel rolling process control instructions.

5. Water treatment process control: Connect with water quality monitoring sensors and achieve remote intelligent control of the sewage treatment process through fiber optic links.

6. Natural gas extraction control: Meet the requirements of explosion-proof working conditions, build redundant communication networks, and ensure the safe and stable operation of extraction equipment.

7. Centralized control of chemical industrial parks: Build a distributed control architecture to achieve collaborative operation of multiple devices and rapid fault switching and self-healing.

8. Compliance control in the pharmaceutical industry: Adapt to clean production environments, ensure traceability of process parameters, and meet industry compliance control requirements.

9. Cement production process control: Resistant to dust and high temperature conditions, linked with kiln equipment to achieve automated control of the entire production process.

10. Process control in the paper industry: Connect with remote I/O of production lines, accurately adjust parameters such as vehicle speed and humidity, and improve product quality stability.

11. Energy and chemical redundancy control: Based on dual fiber optic links, a primary and backup redundancy system is built to avoid unexpected downtime in the production process.

12. Alumina production control: Adapt to corrosive working conditions, achieve remote equipment linkage and parameter optimization for roasting, dissolution and other processes.

13. Industrial old system renovation: Compatible with existing fiber optic cables and racks, low-cost upgrade and replacement of old controllers.

14. Fine chemical process control: Accurately control the temperature and pressure parameters of the reaction kettle to ensure the stability of small-scale and multi batch production.

15. Coal chemical industry management: To cope with high dust and high humidity environments, achieve remote intelligent control of coal mining and coking processes.

The core advantage of this controller board lies in its compatibility with ABB Harmony systems, support for fiber optic point-to-point communication and redundant architecture, fast fault switching, firmware flash upgrade features, compatibility with existing equipment and fiber optic links, and adaptability to distributed control requirements for complex explosion-proof and high-temperature working conditions such as chemical and power industries.

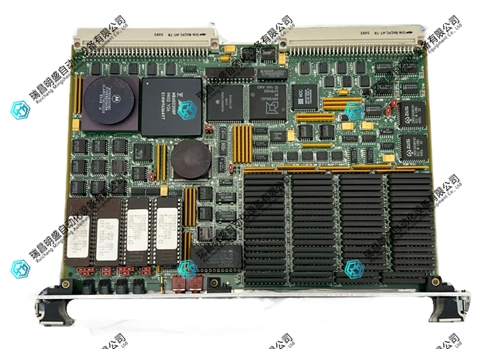

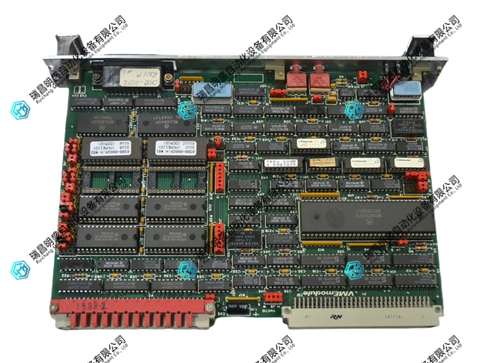

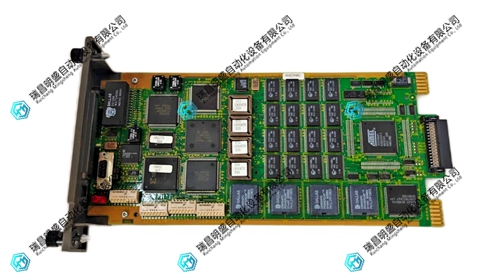

BRC-200控制器板 产品展示

产品视频

3.其他产品

ABB D674A906U01流量计变送器模块

ABB CI857K01 3BSE018144R1控制主板模块

Uniop ETT-VGA-0045触摸屏

4.其他英文产品

BENTLY 3500/33-1-00 Relay Module

RELIANCE S-D4007 High Performance Digital Controller

IC698PSA100 CPU processor module

| AMAT 0100-14006 | TP-5002-2-R | S20360-SRS |

| AMAT 0100-09220 | TP-2207-0 | 0190-72680 |

| AMAT 0100-90251 | TP-2240-3 | 80190-560-01-R |

| AMAT 0100-09306 | PRS-1593D | D3000 |

| AMAT 0100-20032 | PRS-2052F | MMC-BDPV81INA |

| AMAT 0100-40037 | PRS-I623C | 7ML54400GB000AA2 |

| AMAT 0100-00496 | DCW30-32094-C | 0100-71275 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218