1.产 品 资 料 介 绍:

IMASI13模拟输入模块产品应用领域(15条)

1. 火力发电厂:适配ABB Harmony系统,采集汽轮机热电阻(RTD)温度信号,24位分辨率保障机组运行参数精准反馈,为调控提供数据支撑。

2. 石油炼化:接收催化裂化装置压力变送器4-20mA信号,通道独立隔离设计抵御强电磁干扰,确保工艺压力数据稳定采集。

3. 化工园区:采集反应釜热电偶(K型)温度与pH值传感器信号,自动完成冷端补偿,为工艺优化提供精准数据源。

4. 水处理厂:捕获沉淀池液位、浊度及溶解氧模拟信号,支持-100至+100mV信号输入,适配各类水质传感器需求。

5. 冶金工厂:采集高炉炉壁热电阻温度信号,宽温工作特性适配高温工况,实时反馈炉体热态数据规避安全风险。

6. 新能源光伏:接收逆变器输出电流、电压模拟信号,快速完成A/D转换,为光伏电站能效分析提供精准数据。

7. 船舶工业:耐受高湿盐雾环境,采集船舶动力系统油压、水温信号,通道隔离技术保障恶劣工况下数据采集可靠。

8. 制药车间:采集发酵罐温度、压力及搅拌转速模拟信号,满足GMP标准对生产过程数据精准追溯的需求。

9. 食品加工:接收杀菌釜蒸汽压力与温度信号,实时上传至控制系统,确保杀菌工艺参数符合食品安全规范。

10. 智能楼宇:采集HVAC系统温度、湿度传感器0-10V信号,为楼宇节能调控提供实时环境参数支撑。

11. 轨道交通:采集列车制动系统油压、制动片温度模拟信号,快速反馈异常数据,保障行车安全。

12. 实验室科研:适配各类实验设备,采集微小电压(mV级)、电流信号,高精度转换能力满足实验数据精准测量需求。

13. 橡胶制品厂:采集硫化机腔体内温度、压力模拟信号,自动完成工程单位转换,为硫化工艺优化提供数据依据。

14. 市政供热:采集热力管道供回水温度、压力信号,实时监测管网运行状态,助力供热系统精准调控。

15. 航空航天地面测试:采集飞行器部件测试过程中的温度、应力模拟信号,高可靠性保障测试数据精准有效。

IMASI13模拟输入模块 英文资料:

Application areas of IMASI13 analog input module products (15 items)

1. Thermal power plant: adapted to ABB Harmony system, collecting temperature signals of turbine thermal resistance (RTD), 24 bit resolution ensures accurate feedback of unit operating parameters, and provides data support for regulation.

2. Petroleum refining: Receive 4-20mA signals from pressure transmitters in catalytic cracking units, with independent channel isolation design to resist strong electromagnetic interference and ensure stable collection of process pressure data.

3. Chemical Industrial Park: Collect temperature and pH sensor signals from reaction kettle thermocouples (K-type), automatically complete cold end compensation, and provide accurate data sources for process optimization.

4. Water treatment plant: Capture simulated signals of sedimentation tank liquid level, turbidity, and dissolved oxygen, support -100 to+100mV signal input, and adapt to various water quality sensor requirements.

5. Metallurgical factory: Collect temperature signals of blast furnace wall resistance, adapt to high temperature conditions with wide temperature working characteristics, and provide real-time feedback of furnace body thermal state data to avoid safety risks.

6. New energy photovoltaics: Receive analog signals of inverter output current and voltage, quickly complete A/D conversion, and provide accurate data for energy efficiency analysis of photovoltaic power plants.

7. Shipbuilding industry: Tolerant to high humidity salt spray environment, collects oil pressure and water temperature signals of ship power system, and uses channel isolation technology to ensure reliable data collection under harsh working conditions.

8. Pharmaceutical workshop: Collect simulated signals of fermentation tank temperature, pressure, and stirring speed to meet the requirements of GMP standards for accurate traceability of production process data.

9. Food processing: Receive steam pressure and temperature signals from the sterilization kettle, upload them in real-time to the control system, and ensure that the sterilization process parameters comply with food safety regulations.

10. Intelligent buildings: Collect 0-10V signals from HVAC system temperature and humidity sensors to provide real-time environmental parameter support for building energy-saving regulation.

11. Rail transit: Collect simulated signals of train brake system oil pressure and brake pad temperature, quickly feedback abnormal data, and ensure driving safety.

12. Laboratory research: Suitable for various experimental equipment, collecting small voltage (mV level) and current signals, with high-precision conversion capability to meet the precise measurement needs of experimental data.

13. Rubber products factory: Collect temperature and pressure simulation signals inside the vulcanizing machine chamber, automatically complete engineering unit conversion, and provide data basis for optimizing the vulcanization process.

14. Municipal heating: Collect temperature and pressure signals of the supply and return water in the heating pipeline, monitor the operation status of the pipeline network in real time, and assist in precise control of the heating system.

15. Aerospace ground testing: Collect temperature and stress simulation signals during the testing process of aircraft components, ensuring high reliability and accurate and effective testing data.

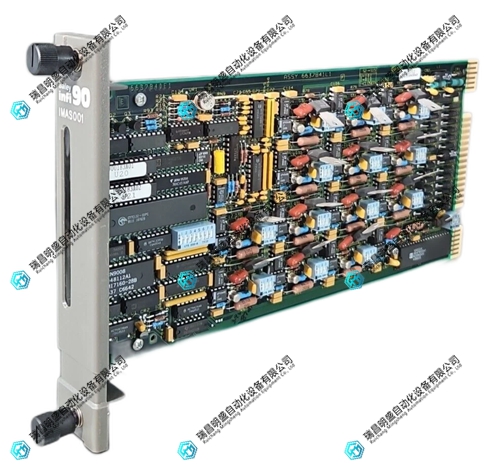

IMASI13模拟输入模块 产品展示

产品视频

3.其他产品

Force CPCI-680CPU模块

BENTLY 125840-02低压交流电源

BENTLY 125680-01 前置器i/o模块

4.其他英文产品

HONEYWELL CC-PFB401 pressure sensor module

Siemens 3RB1257-0KM00 Electronic Overload Protector

Lenze ESMD113L4TXH509 AC servo driver

| AMAT 0100-90221 | AMAT 0190-76027 | VMIVME-7750-746 |

| AMAT 0100-09041 | AMAT 0190-76043 | X-FAN 18 03 |

| AMAT 0100-76267 | AMAT 0190-76050 | 7702 |

| 3BHB015651P0001 | AMAT 0190-76053 | 701-00610-8 |

| AMAT 0190-37178 | AMAT 0190-76101 | C400/10/1/1/1/00 |

| AMAT 0190-54047 | AMAT 0190-76142 | LDGRB-01 3BSE013177R1 |

| AMAT 0190-01486 | AMAT 0190-76150 | 140CPU67160 |

| AMAT 0190-66024 | AMAT 0190-76185 | 3500/72-01-00 140734-08 |

| AMAT 0190-16010 | AMAT 0190-76252 | 369-LO-0-M-0-0-0-E |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218