1.产 品 资 料 介 绍:

620-3032逻辑控制器模块产品应用领域

620-3032作为霍尼韦尔620系列增强型逻辑控制器模块,具备多核逻辑运算、丰富I/O扩展、多协议兼容及宽温抗干扰特性,支持复杂时序控制与系统联动,适配中大型自动化场景需求,广泛应用于15大领域:

1. 石油天然气:实现油气集输系统复杂逻辑控制,联动多节点传感器完成压力、流量分级调控与故障联锁。

2. 电力发电:管控电厂主辅设备协同逻辑,支持水泵、风机集群时序控制,保障发电系统稳定高效运行。

3. 化工加工:编制多反应釜联动逻辑程序,适配温压联动控制,实现工艺链条安全联锁与精准调控。

4. 冶金冶炼:支持冶炼全流程时序控制,联动高温、液位传感器,实现多设备协同与工况自适应调节。

5. 智能制造:作为中大型产线控制核心,支持多工位复杂逻辑联动,实现工序切换与设备协同的精准管控。

6. 轨道交通:适配轨道运维综合控制系统,实现道闸、警示、供电设备逻辑联动,保障运行安全。

7. 船舶工业:耐受盐雾高湿极端环境,控制机舱多系统辅机逻辑,支持船舶设备集群协同运行。

8. 水处理环保:实现多组水泵、电磁阀联动逻辑控制,基于水质参数自动切换运行模式,提升处理效率。

9. 医药生产:支持无菌车间多工序联动控制,满足生产流程合规性要求,保障参数精准稳定。

10. 食品加工:适配自动化生产线扩展需求,管控灌装、杀菌、包装全流程逻辑,实现标准化作业。

11. 汽车制造:编制复杂焊接、装配工位逻辑,支持多机械臂协同控制,提升生产精度与效率。

12. 新能源电站:实现光伏阵列、储能单元集群控制,联动监测系统完成充放电逻辑自适应调节。

13. 楼宇自控:支持大型楼宇多区域暖通、照明、安防系统联动,优化能耗管理与环境调控。

14. 消防联动:实现全区域消防设备逻辑联锁,快速响应消防信号,保障防火、排烟系统协同动作。

15. 旧系统升级:兼容霍尼韦尔620系列架构,扩展I/O接口与控制功能,提升老旧系统自动化水平。

该模块凭借增强型运算能力、灵活扩展特性及严苛工况适配性,为中大型工业自动化系统提供高效、可靠的核心逻辑控制解决方案。

620-3032逻辑控制器模块 英文资料:

620-3032 Logic Controller Module Product Application Fields

As an enhanced logic controller module of Honeywell 620 series, 620-3032 has multi-core logic operation, rich I/O expansion, multi protocol compatibility, and wide temperature anti-interference characteristics. It supports complex timing control and system linkage, adapts to the needs of medium and large automation scenarios, and is widely used in 15 fields:

1. Oil and gas: Realize complex logic control of oil and gas gathering and transportation systems, and link multiple node sensors to achieve pressure and flow classification regulation and fault interlocking.

2. Power generation: Control the collaborative logic between the main and auxiliary equipment of the power plant, support the timing control of water pumps and fan clusters, and ensure the stable and efficient operation of the power generation system.

3. Chemical processing: Develop a multi reactor linkage logic program, adapt to temperature and pressure linkage control, and achieve safe interlocking and precise regulation of the process chain.

4. Metallurgical smelting: Support the timing control of the entire smelting process, link high temperature and liquid level sensors, and achieve multi device collaboration and adaptive adjustment of working conditions.

5. Intelligent manufacturing: As the control core of medium and large-scale production lines, it supports complex logic linkage of multiple workstations, achieving precise control of process switching and equipment collaboration.

6. Rail transit: Adapt to the comprehensive control system of rail operation and maintenance, realize the logical linkage of barrier gates, warnings, and power supply equipment, and ensure operational safety.

7. Shipbuilding industry: Tolerates extreme environments with salt spray and high humidity, controls the logic of multiple auxiliary systems in the engine room, and supports the coordinated operation of ship equipment clusters.

8. Water treatment and environmental protection: Implement multi group water pump and solenoid valve linkage logic control, automatically switch operation modes based on water quality parameters, and improve treatment efficiency.

9. Pharmaceutical production: Supports multi process linkage control in sterile workshops, meets production process compliance requirements, and ensures precise and stable parameters.

10. Food processing: Adapt to the expansion needs of automated production lines, control the entire process logic of filling, sterilization, and packaging, and achieve standardized operations.

11. Automotive manufacturing: Develop complex welding and assembly station logic, support multi robotic arm collaborative control, and improve production accuracy and efficiency.

12. New energy power station: Implement cluster control of photovoltaic arrays and energy storage units, and integrate monitoring systems to achieve adaptive adjustment of charging and discharging logic.

13. Building automation: Support the linkage of multi area HVAC, lighting, and security systems in large buildings, optimize energy consumption management and environmental regulation.

14. Fire linkage: Implement logical interlocking of fire equipment in the entire area, quickly respond to fire signals, and ensure coordinated action of fire prevention and smoke exhaust systems.

15. Old system upgrade: Compatible with Honeywell 620 series architecture, expands I/O interfaces and control functions, and enhances the automation level of old systems.

This module provides efficient and reliable core logic control solutions for medium and large-scale industrial automation systems with enhanced computing capabilities, flexible scalability, and adaptability to harsh operating conditions.

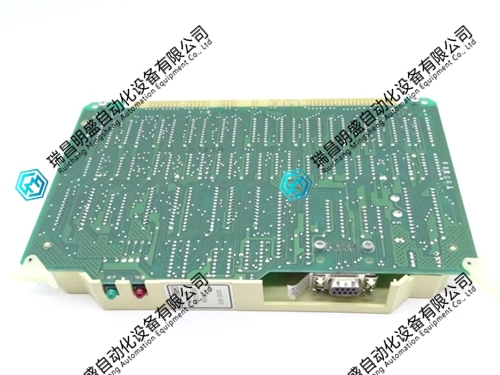

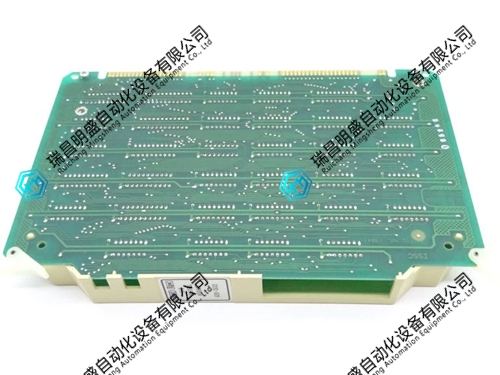

620-3032逻辑控制器模块 产品展示

产品视频

3.其他产品

ABB PFEA112-20 3BSE030369R0020电子控制模块

PIONEER PM3398B-6P-1-3P-E电源模块

HIMA Z7306输入输出模块

4.其他英文产品

VMIC VMIVME-2510B Single Board Computer

B&R 8MSA3L E0-31 servo motor

HIMA F8621A controller module

| 2VM52-000-11 | SV3405-11000 | F31X133PRUAKG1 |

| 2VM52-000-1 | SS9RMPRR11 | F31X136TBGAAG1 |

| 2VD01 | SLO-SYN-230T | 6ES5405-7AB21 |

| 2MB11 | S6002 | 820-07076-000 |

| 2DC21 | SR10000-1P12BLC | 6ES5-490-7LB11 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218