1.产 品 资 料 介 绍:

621-9937并行输入输出模块产品应用领域

霍尼韦尔621-9937并行输入输出模块,搭载16通道并行信号接口,支持5-36VDC宽压输入、3.3-36VDC输出,集成RS-485通讯与Modbus RTU协议,-40℃至85℃宽温工作范围适配严苛工况,可实现高速并行数据交互与设备联动控制,核心应用领域如下:

1. 石油化工领域:对接炼化装置压力、液位传感器,通过并行接口高速传输数据,联动控制执行元件,保障工艺精准调控。

2. 火电运维行业:集成于机组DCS系统,并行采集锅炉、汽轮机运行参数,同步输出控制指令,实现设备联动运维。

3. 有色冶金领域:采集冶炼炉温、液位数据并并行反馈,快速输出调节指令,适配高温高干扰工业场景。

4. 锂电生产行业:并行采集电芯加工参数,同步传输至控制系统,联动调节生产设备,保障电芯一致性。

5. 市政供水系统:实时并行采集水泵压力、流量数据,快速输出启停控制信号,实现供水系统智能化调控。

6. 废气处理领域:并行采集烟气成分、浓度数据,联动控制净化设备运行,确保达标排放与高效处理。

7. 智能物流分拣:通过并行接口同步接收分拣指令与货物定位数据,驱动分拣机械臂精准动作,提升流转效率。

8. 食品包装行业:并行采集包装精度、封口温度数据,实时输出调节指令,契合食品生产卫生与效率需求。

9. 生物制药领域:并行采集反应器温度、pH值参数,同步反馈控制加料、搅拌设备,遵循GMP规范保障生产精度。

10. 玻璃制造行业:采集窑炉温度、玻璃液位数据并并行传输,联动调节加热、成型设备,保障产品质量稳定。

11. 海上油气平台:耐受盐雾腐蚀与宽温工况,并行采集平台设备运行数据,同步输出控制信号,保障海上作业安全。

12. 轨道交通领域:并行采集轨旁信号、车辆状态数据,联动输出调度指令,支撑城轨系统高效有序运行。

13. 汽车零部件制造:并行采集加工设备精度参数,同步反馈调节指令,适配零部件批量生产的高效管控需求。

14. 光伏电站运维:并行采集光伏组件发电参数与储能状态,联动控制充放电设备,优化能源调配效率。

15. 工业设备监测:通过并行接口多维度采集设备振动、温度数据,同步上传至监测平台,实现预测性维护。

注:模块采用紧凑型设计(重量0.6kg),支持与Experion PKS等系统适配,凭借高速并行数据交互与宽工况适配能力,为工业自动化场景提供双向数据传输与联动控制核心支撑。

621-9937并行输入输出模块 英文资料:

621-9937 Parallel Input/Output Module Product Application Fields

Honeywell 621-9937 Parallel Input/Output Module, equipped with 16 channel parallel signal interface, supports 5-36VDC wide voltage input and 3.3-36VDC output, integrates RS-485 communication and Modbus RTU protocol, adapts to harsh working conditions with a wide temperature range of -40 ℃ to 85 ℃, and can achieve high-speed parallel data exchange and device linkage control. The core application areas are as follows:

1. In the field of petrochemicals: docking with pressure and liquid level sensors in refining equipment, high-speed data transmission through parallel interfaces, linkage control of execution components, and ensuring precise process control.

2. Thermal power operation and maintenance industry: Integrated into the unit DCS system, parallel collection of boiler and turbine operating parameters, synchronous output of control instructions, and realization of equipment linkage operation and maintenance.

3. In the field of non-ferrous metallurgy: Collect smelting furnace temperature and liquid level data and provide parallel feedback, quickly output adjustment instructions, and adapt to high temperature and high interference industrial scenarios.

4. Lithium battery production industry: parallel collection of battery cell processing parameters, synchronous transmission to the control system, linkage adjustment of production equipment, ensuring battery cell consistency.

5. Municipal water supply system: Real time parallel collection of water pump pressure and flow data, rapid output of start stop control signals, achieving intelligent regulation of the water supply system.

6. In the field of exhaust gas treatment: parallel collection of flue gas composition and concentration data, linkage control of purification equipment operation, to ensure standard emissions and efficient treatment.

7. Intelligent logistics sorting: By synchronously receiving sorting instructions and cargo positioning data through parallel interfaces, the sorting robotic arm is driven to move accurately, improving circulation efficiency.

8. Food packaging industry: parallel collection of packaging accuracy and sealing temperature data, real-time output of adjustment instructions, in line with the hygiene and efficiency requirements of food production.

9. In the field of biopharmaceuticals: parallel collection of reactor temperature and pH parameters, synchronous feedback control of feeding and stirring equipment, and compliance with GMP standards to ensure production accuracy.

10. Glass manufacturing industry: Collect kiln temperature and glass liquid level data and transmit them in parallel, coordinate and adjust heating and forming equipment to ensure stable product quality.

11. Offshore oil and gas platform: resistant to salt spray corrosion and wide temperature conditions, parallel collection of platform equipment operation data, synchronous output of control signals, ensuring the safety of offshore operations.

12. In the field of rail transit: parallel collection of trackside signals and vehicle status data, linkage output of scheduling instructions, supporting efficient and orderly operation of urban rail systems.

13. Automotive parts manufacturing: parallel collection of precision parameters of processing equipment, synchronous feedback adjustment instructions, and adaptation to the efficient control requirements of mass production of parts.

14. Photovoltaic power station operation and maintenance: parallel collection of photovoltaic module power generation parameters and energy storage status, linkage control of charging and discharging equipment, and optimization of energy allocation efficiency.

15. Industrial equipment monitoring: Multi dimensional data on equipment vibration and temperature are collected through parallel interfaces and synchronously uploaded to the monitoring platform to achieve predictive maintenance.

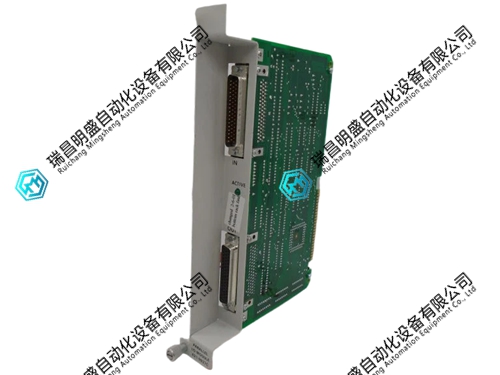

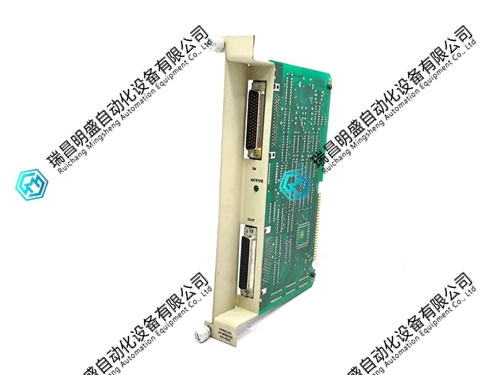

621-9937并行输入输出模块 产品展示

产品视频

3.其他产品

BENTLY 135613-02电源模块

Siemens 6ES193-1CH10-0XA0以太网模块

GE 8521-TC-SA控制器

4.其他英文产品

HONEYWELL 396352-01-4 Thermistor Module

DELTATAU CLIPPERT3 controller module

DEIF SCM-2 encoder module

| 269-100P-120 | CACR-UP130AAB,PCB | F31X111PSHAEG1 |

| 239-RTD-AN-H | PA215T-135 | 720-21216-003 |

| 239-RTD-AN | 6DD1684-0AH0 | 712-450673-00 |

| 239-RTD | 6DD1684-0EE0 | 710-611529-000 |

| 239-AN | 03-145147-00 | 710-658177-2 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218