MOOG D633-313B 伺服阀

1.产 品 资 料 介 绍:

- 直动式 DDV 核心架构:MOOG D633-313B 延续 D633 系列经典直动式(DDV)设计,由永磁线性力马达直接驱动阀芯,省去传统伺服阀的喷嘴挡板先导级,无需外部先导油源即可实现双向位移控制。相比多级结构减少约 30% 传动环节,阀体体积更紧凑,同时大幅降低信号传递滞后,适配对响应速度要求严苛的闭环控制系统,如精密机床液压伺服机构。

- 集成化电控模块设计:内置阀芯位置控制电路板与脉宽调制(PWM)驱动电路,将信号处理、功率放大与阀芯反馈功能高度集成。电路板采用工业级 SMD 贴片工艺,支持 18-32V DC 宽压输入,可直接接收外部控制指令,无需额外配置驱动模块,显著简化系统布线与集成流程,降低设备安装调试难度。

- 抗污染精密结构:阀芯与阀套选用 AISI 440C 马氏体不锈钢材质,经超精密研磨处理,配合间隙小于 1μm,确保液压油流场稳定。表面通过氮化硬化工艺提升耐磨性 3 倍以上,内置 10μm 过滤级滤芯,可耐受 NAS 6 级污染度液压油,搭配可更换防尘密封圈,有效抵御粉尘、杂质侵入,降低恶劣工况下阀芯卡滞故障风险。

- 高压适配与流量特性:最大工作压力可达 35MPa,在 7MPa 阀压降条件下,额定流量覆盖 5-80L/min(根据具体参数细分),能为冶金设备油缸、液压试验台作动器等提供稳定动力输出。即便在 1-5bar 低压差工况下,仍可保持流量输出稳定性,适配多压力等级场景,如注塑机模具开合控制、重型设备液压执行机构驱动。

- 高频响动态响应:频率响应宽达 40-60Hz(±100% 输入信号),100% 阶跃响应时间≤15ms,部分工况下可低至 5ms。线性力马达采用低摩擦设计,配合阀芯位置实时反馈,能快速跟随控制指令调整流量,有效抑制液压系统动态滞后,保障高速运动设备(如自动化生产线机械臂)的控制精度。

- 高精度控制指标:分辨率≤0.1%,滞环误差低于 0.2%,通过线性位置传感器(LVDT)实现阀芯位置闭环控制,确保输入信号与流量输出精准对应。最小可控流量低至 0.1L/min,可满足半导体设备微进给、精密压力调节等精细化需求,如光学元件加工设备的液压伺服定位控制。

MOOG D633-313B 伺服阀 英文资料:

1、 Infrastructure and Design Characteristics

Direct acting DDV core architecture: MOOG D633-313B continues the classic direct acting (DDV) design of the D633 series, with a permanent magnet linear force motor directly driving the valve core, eliminating the need for the nozzle baffle pilot stage of traditional servo valves, and achieving bidirectional displacement control without the need for an external pilot oil source. Compared to the multi-stage structure, which reduces the transmission links by about 30%, the valve body volume is more compact, and the signal transmission lag is significantly reduced, making it suitable for closed-loop control systems with strict response speed requirements, such as precision machine tool hydraulic servo mechanisms.

Integrated electronic control module design: Built in valve core position control circuit board and pulse width modulation (PWM) drive circuit, highly integrating signal processing, power amplification, and valve core feedback functions. The circuit board adopts industrial grade SMD surface mount technology and supports 18-32V DC wide voltage input. It can directly receive external control instructions without the need for additional driver modules, significantly simplifying the system wiring and integration process, and reducing the difficulty of equipment installation and debugging.

Anti pollution precision structure: The valve core and valve sleeve are made of AISI 440C martensitic stainless steel material, which has undergone ultra precision grinding treatment with a clearance of less than 1 μ m to ensure stable hydraulic oil flow field. The wear resistance of the surface is improved by more than 3 times through nitriding hardening process, and it is equipped with a 10 μ m filter element that can withstand NAS level 6 pollution hydraulic oil. It is matched with replaceable dust-proof sealing rings to effectively resist the invasion of dust and impurities, and reduce the risk of valve core jamming failure under harsh working conditions.

2、 Core performance and control accuracy

High pressure adaptation and flow characteristics: The maximum working pressure can reach 35MPa, and under the condition of 7MPa valve pressure drop, the rated flow covers 5-80L/min (subdivided according to specific parameters), which can provide stable power output for metallurgical equipment oil cylinders, hydraulic test bench actuators, etc. Even under low pressure drop conditions of 1-5 bar, the flow output stability can still be maintained, suitable for multi pressure level scenarios such as injection molding machine mold opening and closing control, and heavy-duty equipment hydraulic actuator drive.

High frequency dynamic response: The frequency response is as wide as 40-60Hz (± 100% input signal), with a 100% step response time of ≤ 15ms, and can be as low as 5ms under some working conditions. The linear force motor adopts a low friction design, coupled with real-time feedback of the valve core position, which can quickly follow the control instructions to adjust the flow rate, effectively suppress the dynamic lag of the hydraulic system, and ensure the control accuracy of high-speed moving equipment (such as automated production line robotic arms).

High precision control indicators: resolution ≤ 0.1%, hysteresis error below 0.2%, closed-loop control of valve core position achieved through linear position sensor (LVDT), ensuring accurate correspondence between input signal and flow output. The minimum controllable flow rate is as low as 0.1L/min, which can meet the refined needs of semiconductor equipment such as micro feed and precision pressure regulation, such as hydraulic servo positioning control for optical component processing equipment.

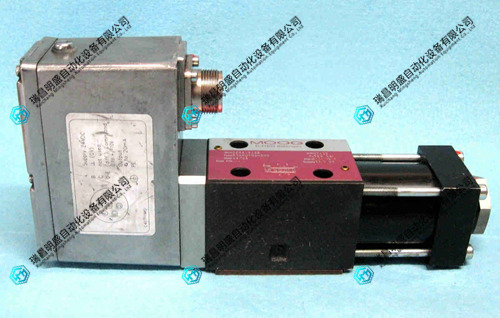

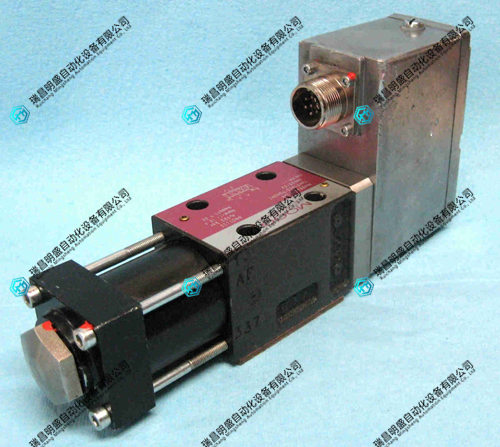

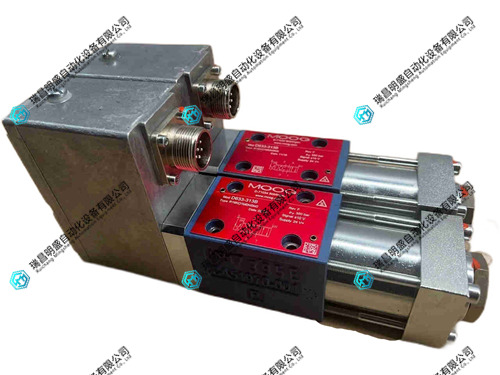

MOOG D633-313B 伺服阀 产品展示

产品视频

3.其他产品

Alcatel-Lucent 53LI1A3AXX控制板

Alcatel-Lucent 3DH03131AAAG控制板

Alcatel-Lucent 3FE66721AB VAI2AK7NAA端口板

4.其他英文产品

NI PXI-2534 Multi Protocol Instrument Control Module

NI PXI-4110 DC Power Module

NI PXI-2503 high-speed differential digital output module

| 5440 | 5ML051 | 4116J89-G02 |

| 5430-230 | HZ172A601 | 4116J81G1 |

| 5430 | SS400-11082/RECEIVER | 4116J81-G01 |

| 5410-012 | SS400-10084 | IMMP101 |

| 5410-010 | SS7B-481MDOR | IMDSM04 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218