Atlas Copco PF4000-G-DN-HW功率对焦控制器

1.产 品 资 料 介 绍:

产品名称

Atlas Copco PF4000-G-DN-HW 功率对焦控制器

产品简介

该控制器是 Atlas Copco Power Focus 4000 系列中的一员,专为驱动和控制 Tensor 系列电动工具而设计,具备高精度、多阶段扭矩控制能力。

型号中的含义如下:

PF4000:Power Focus 4000 系列平台

G:图形界面版本,带有本地显示和操作界面

DN:支持 DeviceNet 工业通信协议

HW:标准硬件配置

主要应用领域

汽车整车与零部件装配

适用于高精度拧紧工序,如发动机、变速箱、底盘、座椅结构、车门铰链等螺栓连接

可与生产线 MES 系统集成,实现扭矩数据追溯和质量控制

新能源汽车与动力电池制造

用于电池模组、电控箱、电驱系统的壳体装配螺丝拧紧

支持扭矩 + 角度复合策略,提升连接可靠性,防止漏拧/过拧

自动化拧紧工作站与机器人装配线

与工业机器人集成,用于自动化拧紧应用

支持 DeviceNet 通信,可与主控系统协同执行拧紧任务

轨道交通、航空及工程机械制造

应用于高安全性要求的装配工序,如悬挂结构、转向部件、舱体连接等

满足扭矩控制一致性、过程监控与螺栓识别需求

家电、电气设备制造

适合小批量、多产品类型的混线拧紧作业

支持程序快速切换与工位切换逻辑

控制器优势概括

支持高精度拧紧控制(±3% 重复性)

多段拧紧策略、角度监控、反扭检测功能

图形化本地界面便于调试和现场设置

可集成多种工业通信协议(如 DeviceNet)

支持与 Tensor STR、EBL、STB 等系列工具配套使用

可上传数据至 MES/SCADA,实现质量追溯和产线协同

英文资料:

product name

Atlas Copco PF4000-G-DN-HW Power Focus Controller

Product Introduction

This controller is a member of the Atlas Copco Power Focus 4000 series, designed specifically for driving and controlling Tensor series power tools, with high-precision, multi-stage torque control capabilities.

The meaning of the model is as follows:

PF4000: Power Focus 4000 Series Platform

G: Graphic interface version with local display and user interface

DN: Supports DeviceNet industrial communication protocol

HW: Standard hardware configuration

Main application areas

Assembly of automobiles and their components

Suitable for high-precision tightening processes, such as bolt connections for engines, transmissions, chassis, seat structures, door hinges, etc

Can be integrated with the MES system of the production line to achieve torque data traceability and quality control

New energy vehicles and power battery manufacturing

Tightening of screws for housing assembly of battery modules, electrical control boxes, and electric drive systems

Support torque+angle composite strategy to improve connection reliability and prevent missed/over twisting

Automated tightening workstation and robot assembly line

Integrated with industrial robots for automated tightening applications

Supports DeviceNet communication and can collaborate with the main control system to perform tightening tasks

Rail transit, aviation, and engineering machinery manufacturing

Applied to assembly processes with high safety requirements, such as suspension structures, steering components, cabin connections, etc

Meet the requirements of torque control consistency, process monitoring, and bolt identification

Manufacturing of household appliances and electrical equipment

Suitable for mixed line tightening operations with small batches and multiple product types

Support fast program switching and workstation switching logic

Summary of controller advantages

Support high-precision tightening control (± 3% repeatability)

Multi stage tightening strategy, angle monitoring, anti twist detection function

The graphical local interface facilitates debugging and on-site setup

Can integrate multiple industrial communication protocols (such as DeviceNet)

Support for use with Tensor STR, EBL, STB and other series of tools

Can upload data to MES/SCADA to achieve quality traceability and production line collaboration

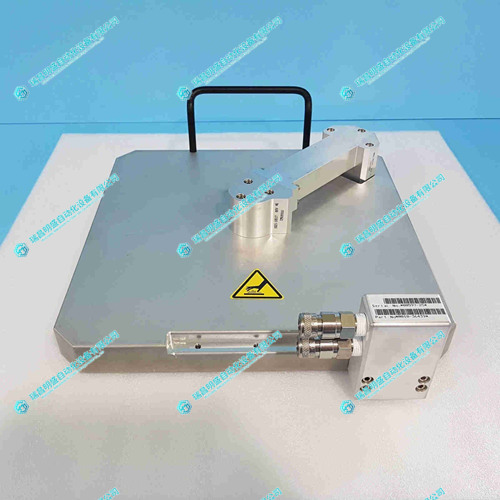

2.产 品 展 示

3.其他产品

4.其他英文产品

ABB 70EB01b-E digital input module

ABB 70BV05a-ES bus controller module

| SR3632-4336-7-48C | 531X306LCCBEM2 | IC3600TPCD1A |

| SR3632-382-2-48B | AMAT 0100-90697 | IC3600TPAM1 |

| SR3632-2094-48B | AMAT 0100-00039 | 26390582-BM DSTK129 ABB |

| SR3624-8291-7-56BC-CU-250210 | AMAT 0100-00736 | 57520001-A DSTC120 ABB |

| SR3624-8291-7-56BC-CU | AMAT 0100-00669 | PFEA 113-65.2PXC |

| SR3624-8291-48B | AMAT 0100-02134 | PFEA 112, IP 65 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218