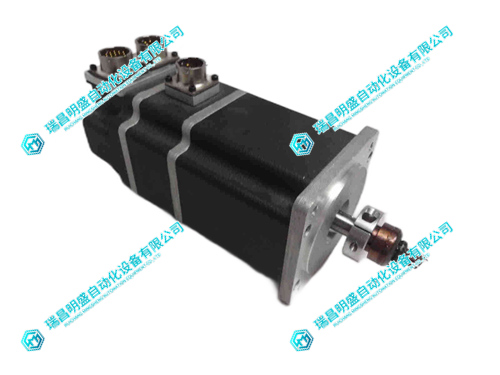

GIDINGS&LEWIS 401-30236-20伺服电机

1.产 品 资 料 介 绍:

英文资料:

GIDINGS&LEWIS 401-30236-20 servo motors play an indispensable role in multiple key fields with their outstanding performance. The following will provide a detailed introduction to the application areas of this model of servo motor:

Numerical Control Mechanical Equipment: This model of servo motor is a key power component in the field of numerical control machine tools, commonly used in milling machines, lathes, boring machines, and other equipment. During the operation of the milling machine, it precisely drives the feed axis, ensuring that the tool moves with micrometer level accuracy. Whether it is complex contour milling or fine groove machining, the machining accuracy can be guaranteed within a very small tolerance range, and high-speed cutting can be achieved, greatly reducing the machining cycle. In lathe machining, its precise control over the spindle and tool holder results in extremely low surface roughness and high dimensional accuracy of the machined workpiece, making it suitable for precision shaft parts machining. During boring machine operation, it can stably drive the boring bar to achieve high-precision boring, ensuring that the roundness, cylindricity, and other positional tolerances of the hole meet strict standards, providing high-precision and high-efficiency machining support for the mechanical manufacturing industry.

Industrial automation production line: In the scene of industrial automation production line, this servo motor shows its skills. When driving the conveyor mechanism, it can quickly respond to the start stop signal of the production line, accurately locate the materials on the conveyor belt, avoid collision and misalignment, and ensure smooth product flow. The sorting device relies on its precise control to accurately sort products to their corresponding positions in a very short time based on their size, weight, color, and other attributes, greatly improving sorting efficiency. At the assembly station, it assists the robotic arm in achieving high-precision component assembly, achieving sub millimeter level assembly accuracy, improving product assembly quality, endowing the production line with high flexibility, easily responding to the needs of multiple varieties and small batch production, and promoting the level of industrial automation to a new height.

Robots and motion control systems: For industrial robots, this servo motor, as the core component of joint drive, is the guarantee for flexible and precise motion of the robot. When the robot performs a handling task, it quickly responds to control instructions and drives all joints to work together, enabling the robotic arm to grasp and place objects with extremely high repeatability accuracy even under high-speed motion, ensuring a stable and reliable handling process. In complex trajectory operations such as welding and spraying, it can ensure that the robot end effector strictly follows the preset trajectory, the weld seam is uniform and beautiful, and the coating thickness is consistent, greatly improving the stability and accuracy of robot operations. It is widely used in industries such as automotive manufacturing and electronics production that require strict precision for robot operations.

Precision instruments and experimental equipment: In the field of precision instruments and experimental equipment with almost stringent requirements for motion accuracy, GIDINGS&LEWIS 401-30236-20 servo motors have significant advantages. In semiconductor processing equipment, its high-resolution characteristics enable the precision of etching, photolithography and other processes during wafer processing to reach the nanometer level, ensuring a high yield rate for chip manufacturing. In optical detection instruments, it smoothly drives the optical platform and detection components to achieve micrometer level displacement adjustment, ensuring accurate and reliable detection results

2.产 品 展 示

3.其他产品

ABB 216AB61 HESG324013R0100 HESG435572P1控制模块

ABB 216BM61b HESG448267R1021端子接头

ABB 216DB61 HESG324063R100 HESG216882模块

4.其他英文产品

IW93-2 HESG440356R1 HESG216678B module

NF93A-2 HESG440280R2 module

SST-PFB-SLC Communication module

| AMAT 0100-09010 | AMAT 0190-09437 | AMAT 0190-20033 |

| AMAT 0090-02830 | AMAT 0190-09445 | AMAT 0190-20040 |

| AMAT 0100-03499 | AMAT 0190-09459 | AMAT 0190-20050 |

| AMAT 0100-03068 | AMAT 0190-09466 | AMAT 0190-20063 |

| AMAT 0100-03920 | AMAT 0190-09468 | AMAT 0190-20081 |

| AMAT 0100-00793 | AMAT 0190-09469 | AMAT 0190-20085 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218