TOYOTA PRS-3140C定位附加板

1.产 品 资 料 介 绍:

- 输入信号类型:支持编码器、光电传感器、磁性开关等位置检测信号,可适配多种检测设备。

- 分辨率:可达微米级(依据配置的传感器精度),能满足高精度定位需求。

- 接口类型:配备高速数字接口、标准工业通信端口(如 RS-422、CAN 或专用总线),方便与其他系统连接通信。

- 响应时间:具有毫秒级实时处理能力,确保对位置变化的快速响应。

- 工作电压:DC 5V / 12V(视设计而定),适配不同的供电环境。

- 工作环境:可在 - 10℃~+55℃温度范围内工作,且采用抗振动、防尘设计,能适应工业生产的复杂环境。

英文资料:

TOYOTA PRS-3140C positioning add-on board is an extended functional module specifically designed for automation control systems, with the main function of achieving high-precision positioning control and position detection. It is usually used in conjunction with the main control board or motion control system to provide accurate position data support for industrial robots, automated production lines, and precision assembly equipment. Its design goal is clear, which is to improve the repeatability accuracy and dynamic response speed of the equipment, thereby ensuring the stability and consistency of the production process.

1、 Technical parameters (example, specific values need to be confirmed according to the device version)

Input signal type: Supports position detection signals such as encoders, photoelectric sensors, magnetic switches, etc., and can be adapted to various detection devices.

Resolution: up to micrometer level (depending on the accuracy of the configured sensor), capable of meeting high-precision positioning requirements.

Interface type: Equipped with high-speed digital interfaces and standard industrial communication ports (such as RS-422, CAN, or dedicated bus) for easy connection and communication with other systems.

Response time: With millisecond level real-time processing capability, ensuring fast response to location changes.

Working voltage: DC 5V/12V (depending on the design), suitable for different power supply environments.

Working environment: It can work within the temperature range of -10 ℃ to+55 ℃, and adopts anti vibration and dust-proof design, which can adapt to the complex environment of industrial production.

2、 Application scenarios

(1) Industrial robot positioning

Suitable for precise positioning control of end effectors in articulated and Cartesian robots, it can achieve precise path execution in processes such as welding, spraying, and handling, ensuring the accuracy of robot operations.

(2) Automated assembly line

Real time detection and adjustment of workpiece position can effectively ensure assembly accuracy, reduce quality defects caused by position errors, and improve assembly quality and efficiency.

(3) Precision machining equipment

It can be applied to CNC machine tools, laser cutting, precision drilling and other equipment that require high-precision positioning, which helps improve machining consistency and dimensional accuracy, and meets the strict requirements of precision machining.

(4) Conveyor and Sorting System

Dynamic position capture can be achieved on high-speed conveyor belts, supporting automatic material sorting and fixed-point parking, improving the efficiency and accuracy of conveying and sorting.

In summary, the TOYOTA PRS-3140C positioning attachment board plays an important role in the field of automation control with its high-precision positioning control and wide applicability, providing strong guarantees for the precise operation of various equipment.

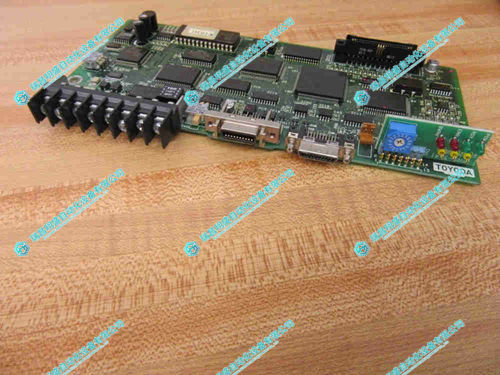

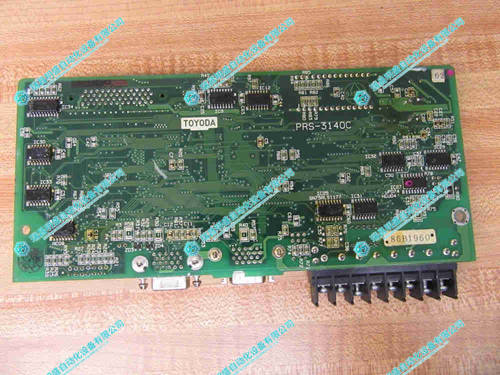

2.产 品 展 示

3.其他产品

4.其他英文产品

ALSTOM 3EST125-975 DCC2382A Control Pane

Asea 2668-184-280 12 slot control board

HAAS 93-32-3550J Intelligent Driver

| 0252671-000 | SL5C-101 | 0058069-000 |

| 0239332-000 | SSM-48-F | 0057956-002 |

| 0157544-004 | HZ170A60107 | 0052196-008 |

| 0149395-000 | HD603A622 | 0052196-007 |

| 0149329-004 | HZ172A605 | 0049727-001 |

| 0134014-002 | HG111A6 | 00383015-000 |

Contact: +86 15270269218