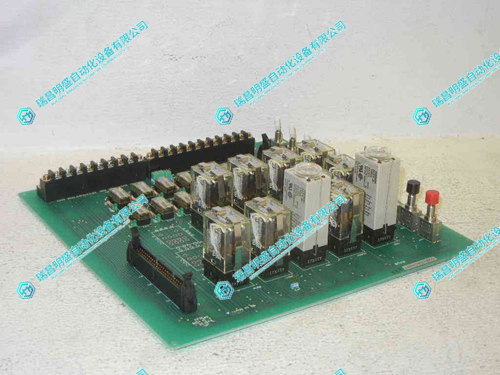

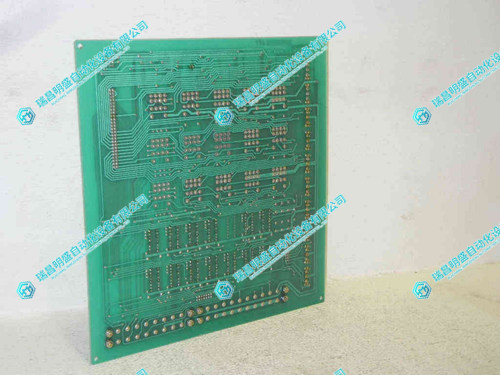

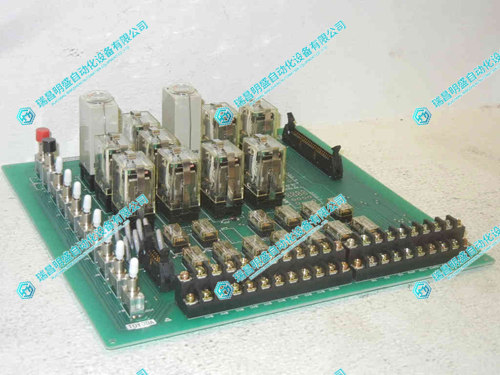

TOYOTA TP-8076-2逻辑控制器板

1.产 品 资 料 介 绍:

英文资料:

TOYOTA TP-8076-2 Logic Controller Board Characteristics Description

Core functions

The TOYOTA TP-8076-2 logic controller board is the "logic center" in the field of industrial automation. With high-speed logic processing capabilities, it analyzes and judges signals from various devices, and then issues precise control instructions. It can integrate various information, coordinate the actions of different devices, and ensure the efficient operation of the entire system according to preset logic. It is an indispensable core control component in TOYOTA automation systems and industrial equipment.

Performance Highlights

High speed logic processing: With the ability to quickly analyze signals and make logical judgments, it can process complex control requirements in a short period of time, ensuring timely response of equipment actions.

Stable and reliable: Adopting industrial grade design standards, it can maintain stable operation in complex environments on industrial sites, providing solid support for the continuous operation of the system.

Multi interface compatibility: Equipped with rich interfaces, it can smoothly connect with various sensors, actuators, and other control devices, adapting to different industrial scenarios.

Application field details

Industrial automation production line: Implement centralized logical control over sensors and actuators in the production line, enabling automatic coordination of assembly line equipment, ensuring synchronized actions in each link, and improving production efficiency.

Robot system control: responsible for the motion logic management of industrial robots, supporting the path planning, speed regulation, and coordination of multi axis actions of robotic arms, enabling robots to accurately complete various tasks.

Mechanical processing and assembly equipment: applied to CNC machine tools, machining centers and other equipment to make logical judgments and trigger corresponding actions; At the same time, control the operation of automated assembly equipment to ensure the accuracy of processing and assembly processes.

Testing and Inspection System: Responsible for signal processing and logic control in automated testing benches and inspection equipment, which helps improve the efficiency and accuracy of inspection and ensure the reliability of inspection results.

Logistics and Warehouse Automation: Manage the movements of conveyor belts, sorting systems, and warehouse robots, coordinate the work between data collection and actuators, and make the logistics and warehousing process smoother.

Multi axis equipment and synchronous control: capable of achieving synchronous actions of multi axis mechanical equipment, widely used for coordinated control of packaging, handling, and assembly machinery, ensuring efficient collaboration of these devices.

2.产 品 展 示

3.其他产品

4.其他英文产品

1TGE120011R1111 Controller Module

PROSOFT MVI46-MCM communicatio

Kollmorgen S72402-NANANA servo amplifier

| PFTL101BE | AMAT 0100-35082 | PFRL101B |

| PFTL101B | AMAT 0100-90139 | PFRL101D 5KN |

| PFRL101D | AMAT 0100-00642 | PFTL 101BE-2.0KN |

| PFRL101C | AMAT 0100-09292 | PFTL 201CE-50.0KN |

| PFRL101B | AMAT 0100-00069 | PFTL 101BER-5.0KN |

| PFRL101A | AMAT 0100-35170 | PFTL 101AER-0.5 |

| PFEL113 | AMAT 0100-90861 | PFTL101A-1.0KN 3BSE004166R1 1.0KN |

Contact: +86 15270269218