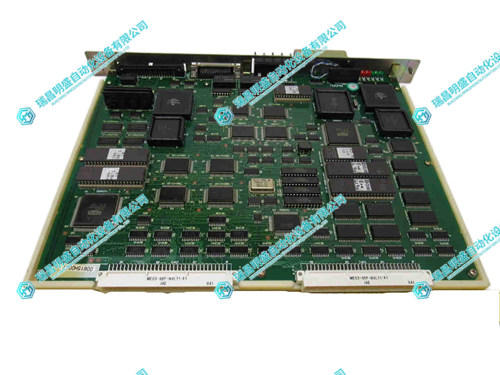

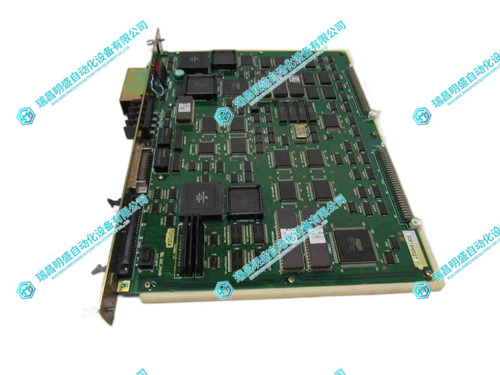

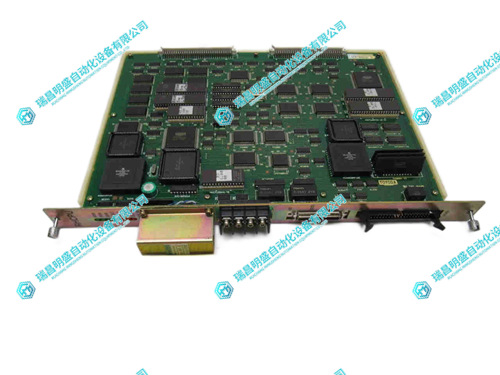

TOYOTA TP-8132-3 控制主板

1.产 品 资 料 介 绍:

英文资料:

TOYOTA TP-8132-3 Control Board Characteristics Description

Core functions

The TOYOTA TP-8132-3 control motherboard is the "command core" of industrial automation systems, responsible for centralized control and coordination of various devices with high-speed processing capabilities, rich interface configurations, and reliable design. It can receive and process various signals, issue precise control instructions, and ensure the efficient and orderly operation of the entire automation system. It is an indispensable core control unit in the TOYOTA automation system.

Performance Highlights

High speed processing: Equipped with high-performance processing units, it can quickly process complex control logic and massive data, providing powerful computational support for multi device collaborative operation, ensuring timely issuance of control instructions.

Rich interfaces: Equipped with multiple types of interfaces, it can flexibly connect with various devices such as sensors, actuators, and other control modules to meet the connection needs of different industrial scenarios and improve system compatibility.

Stable and reliable: Adopting industrial grade design standards, high-quality components are selected, which have good anti-interference, high temperature resistance, and vibration resistance performance. They can maintain stable operation in complex industrial environments and ensure the continuous operation of the system.

Application field details

Industrial robot control: responsible for controlling the multi axis motion of the robotic arm, accurately achieving path planning, speed regulation, and synchronization of actions on each axis; Simultaneously supporting the collaborative operation of robot end tools and sensors, enabling robots to efficiently complete complex tasks.

Automated production line: Centralize the management of various equipment on the production line, coordinate the actions of conveyor belts, sorting devices, assembly machinery and other equipment, optimize the production process, thereby improving the efficiency of the production line and the processing accuracy of products.

Mechanical processing equipment control: As the core control component of CNC machine tools and machining centers, it can quickly process input signals, achieve automated operation of machining processes and precise positioning of workpieces, and improve the quality and efficiency of mechanical processing.

Testing and Inspection System: Undertake data acquisition and control work in the automated testing bench to ensure the standardization and accuracy of the inspection process, improve inspection efficiency and stability of results.

Logistics and warehousing automation: Control the operation of sorting systems, conveying equipment, and warehousing robots to achieve efficient coordination and real-time monitoring of their actions, making the logistics and warehousing process smoother and more efficient.

Multi axis and synchronous control system: supports synchronous operation of multi axis equipment, widely used for coordinated control of packaging, assembly, and handling machinery, ensuring consistent action and seamless cooperation of these devices during operation.

2.产 品 展 示

3.其他产品

4.其他英文产品

LAM 810-800081-016 CPU motherb

Siemens 6ES7291-8GC00-0XA0 cartridge

Kollmorgen MMC-SD-0.5-230-D servo drive

| PCE800 | 6SC9837-0KA01 | MC-TDODI3 |

| PCD231B PCD231B101 3BHE025541R0101 | MC-TAIH22 | |

| PC844-XYZ-T | MC-PC1X02 | |

| PC844-XYZ-N | MC-PAOY22 | |

| PC844-XYZ-F | MC-TAIH03 | |

| PC844-XYZ-A | MC-TDIY22 |

Contact: +86 15270269218