TOYOTA TP1875-6 输入输出模块

1.产 品 资 料 介 绍:

TOYOTA TP-1875-6 Input/Output Module Characteristics Description

Core functions

The TOYOTA TP-1875-6 input/output module is an important signal processing and control unit in the field of industrial automation, which can achieve bidirectional interaction of various signals. It can not only collect input signals from sensors, switches and other devices in a centralized manner, but also output control instructions to actuators and other devices, building an efficient signal transmission bridge between the control system and on-site equipment to ensure the smooth operation of various automation systems.

Performance Highlights

Multi channel design: With multiple input and output channels, it can centrally manage multiple signals, meet the needs of multiple devices accessing simultaneously, and improve the integration and signal processing efficiency of the system.

High reliability: Using industrial grade components and stable circuit design, it has good anti-interference ability and can work continuously and stably in complex industrial environments, reducing the probability of failure.

High speed response: The collection of input signals and the transmission of output commands are fast, which can respond to the control requirements of the system in a timely manner, ensuring the real-time and accuracy of equipment actions.

Flexible adaptation: Strong compatibility, can be used in conjunction with various sensors, actuators, and control devices, suitable for different industrial scenarios, and reduces the difficulty of system integration.

Application field details

Industrial automation production line: Centralize signal acquisition and control of various sensors, switches, and actuators, coordinate the actions of production line equipment, promote efficient operation of automated assembly lines, and reduce manual intervention.

Robot system control: Collecting signals from robot sensors and controlling servo motors or actuators to achieve logical control and status monitoring of multi axis movements of the robotic arm, ensuring precise operation of the robot.

Mechanical processing and assembly equipment: responsible for managing the input and output signals of machine tools, machining centers, or assembly equipment, supporting process automation and action logic control, and improving the accuracy and efficiency of mechanical processing and assembly.

Testing and testing equipment: Collect data from sensors of testing equipment, and output control signals to achieve process control of automated testing benches and testing systems, ensuring the standardization of testing and testing work.

Logistics and warehousing automation: Signal processing of sensors and actuators in conveying, sorting, and handling equipment to enable logistics equipment to operate more accurately, improving operational efficiency and accuracy.

Multi device collaborative control system: supports multi-channel centralized management, enabling collaboration and linkage between multiple devices, suitable for complex automation scenarios such as packaging, handling, and sorting, ensuring seamless cooperation among devices.

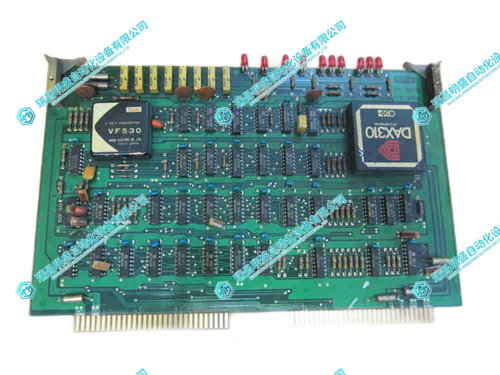

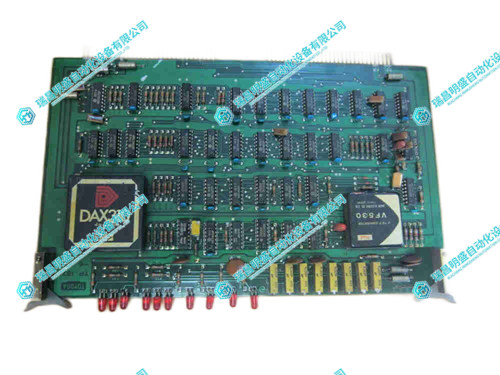

2.产 品 展 示

3.其他产品

Bachmann IPC1412 FRE CM1G1 1G CF8G XPE通信处理器

4.其他英文产品

YT204001-KA/5 voltage signal regulator

ASEA DSPC150 Robot Control Board

| PC834-XYZ-T | AMAT 0100-00070 | 57390001-7 D5001 SB5032 ABB |

| PC834-XYZ-N | AMAT 0100-00986 | PMKHRMBRC3000A |

| PC834-XYZ-A | AMAT 0100-18040 | NKTK01-10 |

| PC834-106-N | AMAT 0100-00054 | 7LD21 |

| PC834-105-N | AMAT 0100-90259 | HESG447271R0002 70BK03B-ES |

Contact: +86 15270269218