TOYOTA 24210-21442-71 控制器模块

1.产 品 资 料 介 绍:

- 类型:控制器 / CPU 控制板

- 适用机型:TOYOTA 7 系列电动叉车(像 7FBCU25 等型号)

- 功能:收集传感器数据、处理驾驶员的操作指令、输出控制信号

- 安装位置:叉车驾驶操作台的控制面板内部

- 维修属性:支持 OEM 替换和再制造维修,通常的保修期限为 6 至 36 个月

- 电动叉车驱动控制:对行驶电机和泵电机开展逻辑运算与控制,保障叉车能够平稳地启动、停止以及进行速度调节。

- 液压系统管理:与液压泵和电磁阀控制相互配合,实现货叉升降、倾斜以及侧移的精确操作。

- 安全防护控制:实时监控电池状态、刹车信号以及各类传感器的反馈信息,避免出现误操作和过载情况。

- 操作面板信号处理:接收驾驶员从操作面板输入的指令,并协调完成控制动作。

- 车队管理维护:借助控制板的数据可以进行故障诊断和维护工作,提升叉车运行的可靠性。

英文资料:

Introduction to TOYOTA 24210-21442-71 Controller Module

Product Overview

The TOYOTA 24210-21442-71 controller module is an electronic control device exclusive to Toyota forklifts, and can be regarded as the core CPU control board of electric forklifts. It is installed inside the control panel and its main function is to interpret the driver's operating signals and coordinate the operation of the drive system, steering system, and hydraulic actuator. This module provides intelligent control and safety assurance for the entire vehicle, and is a crucial electronic component in the Toyota 7 series electric forklift.

Technical parameters (typical features)

Type: Controller/CPU Control Board

Applicable models: TOYOTA 7 series electric forklifts (such as 7FBCU25 models)

Function: Collect sensor data, process driver's operation instructions, output control signals

Installation location: Inside the control panel of the forklift driving console

Repair attribute: Supports OEM replacement and remanufacturing repair, with a typical warranty period of 6 to 36 months

Application scenarios

Electric forklift drive control: Perform logical operations and control on the driving motor and pump motor to ensure smooth starting, stopping, and speed adjustment of the forklift.

Hydraulic system management: Cooperate with hydraulic pumps and solenoid valve control to achieve precise operation of fork lifting, tilting, and lateral movement.

Safety protection control: Real time monitoring of battery status, brake signals, and feedback information from various sensors to avoid misoperation and overload situations.

Operation panel signal processing: Receive commands input by the driver from the operation panel and coordinate to complete control actions.

Fleet management and maintenance: With the help of control board data, fault diagnosis and maintenance work can be carried out to improve the reliability of forklift operation.

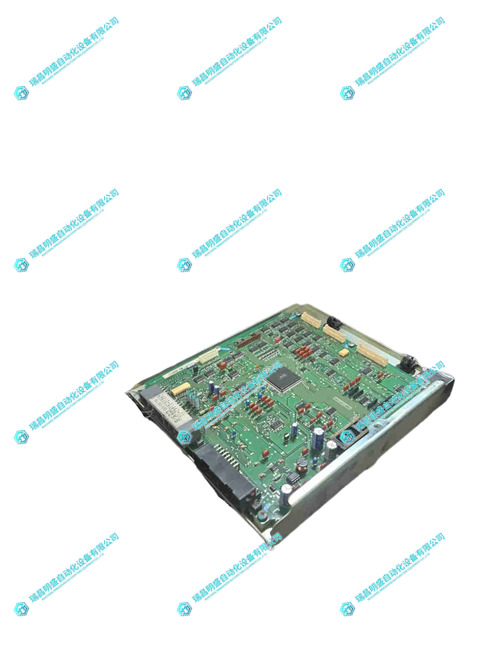

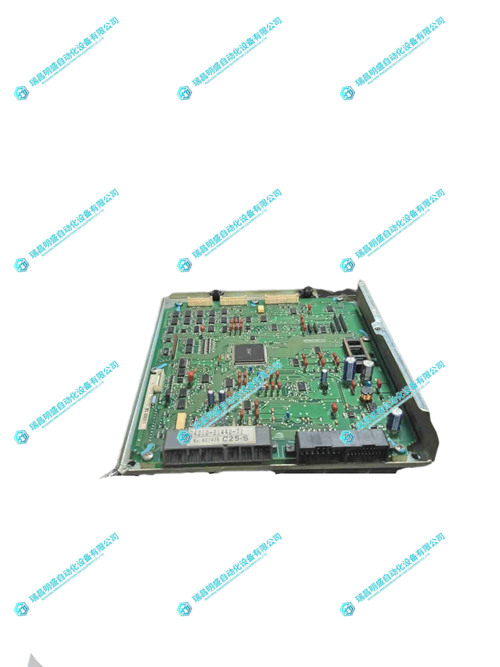

2.产 品 展 示

3.其他产品

4.其他英文产品

ASEA E-31709 Robot Circuit Board

IS200EPSMG1ABB Analog Input Module

| ICS TRIPLEX T3464 PN200158 | SS930-10000 | 6DD1805-5DA0 |

| ICS TRIPLEX T3464 | 5410-0002 | 6DD1842-0AD0 |

| ICS TRIPLEX T3441A | SLO-SYN230EPI | 6DD1842-0AB1 |

| ICS TRIPLEX T3420A | SS2000D3 | 6DD1842-0AB0 |

| ICS TRIPLEX T3419 | SS2000M-D7 | 6DD1801-5DA8 |

| ICS TRIPLEX T3404 | SS410-10000 | 6DD1688-1AC1 |

Contact: +86 15270269218