TOYOTA Fi-DST-1CN-212接口模块

1.产 品 资 料 介 绍:

- 兼容性出色:能够与丰田多款叉车控制器及相关接口设备相互配合工作,保障系统通信的可靠性,让不同设备之间的连接更加顺畅。

- 信号传输稳定:内部电路经过特殊设计,可有效消除干扰和信号衰减问题,确保数据与控制信号能够稳定传递,减少信号传输过程中的误差。

- 接口功能多样:支持数字量、模拟量以及脉冲信号的输入输出,可与多种传感器和执行器相连接,满足不同设备的信号交互需求。

- 耐用性强:模块采用了耐振动、耐温和防尘的设计,能够适应叉车及工业环境的复杂条件,适合长期在这样的环境中使用。

- 安装维护简便:采用模块化设计,方便进行快速安装、拆卸和更换,有助于降低维护成本,减少设备停机时间。

- 叉车控制系统:在叉车控制系统中,它负责接收驾驶员的操作信号和传感器数据,并将这些信息输出到电机、液压阀及其他执行单元,保障叉车各项操作的顺利进行。

- 液压及驱动管理:辅助主控制器对液压泵、电机驱动及辅助设备进行协调控制,提升液压系统和驱动系统的工作效率。

- 安全与报警系统:用于连接安全开关、警报装置和限位传感器,构建起整车的安全防护体系,及时发出安全警报并采取相应防护措施。

- 工业自动化设备接口:还能扩展应用到自动化搬运车、堆高机等设备上,作为这些设备的控制与数据采集模块,助力工业自动化的实现。

英文资料:

Introduction to TOYOTA Fi-DST-1CN-212 Interface Module

Product Overview

TOYOTA Fi-DST-1CN-212 is an interface module suitable for Toyota electric forklifts and industrial automation equipment. Its core function is to connect the controller with external signal devices to achieve data transmission and signal communication. As a critical part of the system signal chain, it ensures that the main controller accurately receives input information from sensors and operation panels, while smoothly outputting control instructions to the execution unit.

Product Features

Excellent compatibility: It can work together with multiple Toyota forklift controllers and related interface devices to ensure the reliability of system communication and make the connection between different devices smoother.

Stable signal transmission: The internal circuit is specially designed to effectively eliminate interference and signal attenuation issues, ensuring stable transmission of data and control signals and reducing errors during signal transmission.

Diverse interface functions: supporting input and output of digital, analog, and pulse signals, and can be connected to various sensors and actuators to meet the signal interaction needs of different devices.

Strong durability: The module adopts a vibration resistant, temperature resistant, and dust-proof design, which can adapt to the complex conditions of forklifts and industrial environments, and is suitable for long-term use in such environments.

Easy installation and maintenance: Adopting a modular design, it facilitates quick installation, disassembly, and replacement, helping to reduce maintenance costs and minimize equipment downtime.

Product application areas

Forklift control system: In the forklift control system, it is responsible for receiving the driver's operation signals and sensor data, and outputting these information to the motor, hydraulic valve, and other execution units to ensure the smooth operation of the forklift.

Hydraulic and Drive Management: The auxiliary main controller coordinates and controls the hydraulic pump, motor drive, and auxiliary equipment to improve the efficiency of the hydraulic and drive systems.

Safety and alarm system: used to connect safety switches, alarm devices, and limit sensors, build a safety protection system for the entire vehicle, issue safety alarms in a timely manner, and take corresponding protective measures.

Industrial automation equipment interface: It can also be extended to automatic handling vehicles, stackers and other equipment, serving as the control and data acquisition module for these devices, and assisting in the realization of industrial automation.

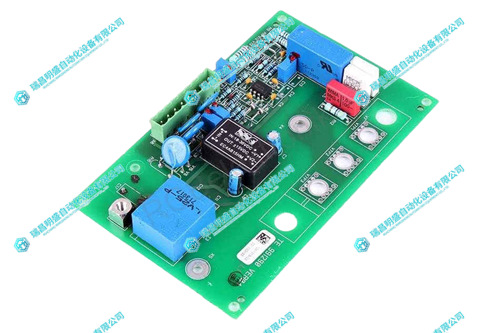

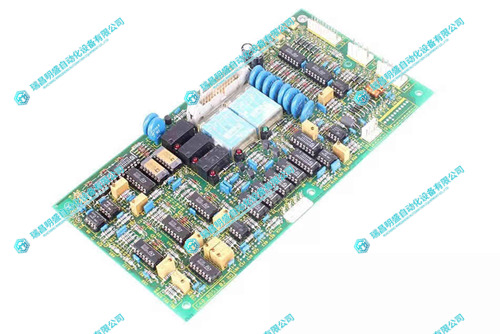

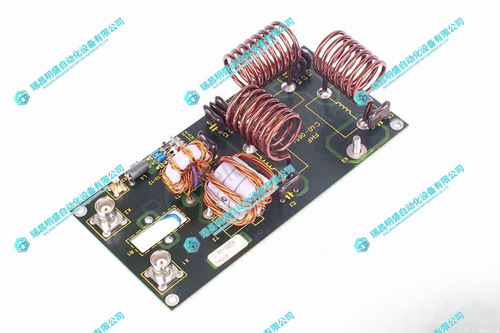

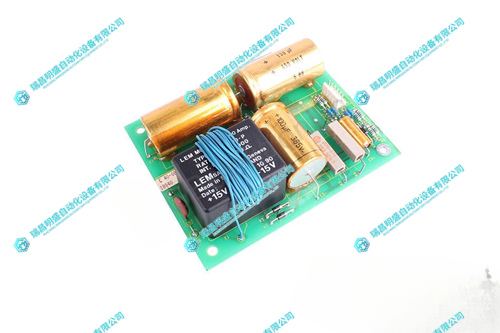

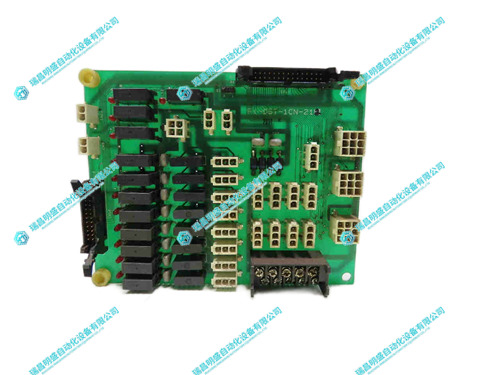

2.产 品 展 示

3.其他产品

4.其他英文产品

Teknic SST-1500-XCX Digital Servo Drive

ABB SB822 3BSE018172R1 rechargeable

| AMAT 0100-71172 | 53401-13380-71 | 0201925 |

| AMAT 0100-01-252 | 53401-U1162-71 | CDL-MICLE-FWAM |

| AMAT 0100-76088 | 53401-U2230-71 | 60M500-05-00 |

| AMAT 0100-98072 | 00591-32004-81 | 3AY1715-6L |

| AMAT 0100-09307 | 00591-63085-81 | 8LS2020 C162 |

| AMAT 0100-00063 | 00591-32005-81 | FC-R/P82/N/12 |

Contact: +86 15270269218