TOYOTA 24240-40530-71控制器

1.产 品 资 料 介 绍:

- 电动叉车驱动控制:负责管理行驶电机的启动、停止、加速、减速以及方向切换,通过精准的控制逻辑,实现叉车平稳且安全的行驶状态,满足不同作业环境下的移动需求。

- 液压系统管理:对液压泵和电磁阀的动作进行协调,精准控制货叉的升降、倾斜、侧移等操作,确保货物在装卸和搬运过程中能够按照预期精准动作,提升作业效率。

- 操作信号采集与处理:接收驾驶员从手柄、踏板和按钮发出的操作信号,并将这些信号快速转换为执行指令,保证操作的精确性和响应的及时性,实现驾驶员操作意图与设备动作的无缝衔接。

- 安全监控与保护:实时监测电池、电机及各类传感器的状态,一旦检测到过载、过压、过流及限位等异常情况,能立即触发保护机制,有效提升操作过程的安全性,降低设备损坏风险。

- 辅助设备控制:对叉车的灯光、蜂鸣器、显示面板等辅助装置进行控制,灯光在光线不足时提供清晰照明,蜂鸣器在关键操作时发出警示,显示面板实时反馈设备运行状态,从而优化操作的便利性与安全性。

- 车队管理与维护:支持对设备运行数据的采集和故障诊断,这些数据为制定科学合理的维护计划和高效的运行管理提供了有力依据,有助于延长设备使用寿命,降低运维成本。

- 工业自动化设备应用:除电动叉车外,还可扩展应用到自动化搬运车、堆高机及其他需要集中控制驱动与液压系统的工业车辆中,为工业自动化生产提供稳定可靠的控制支持。

英文资料:

Introduction to TOYOTA 24240-40530-71 Controller

Product application field description

TOYOTA 24240-40530-71 controller is a control device that plays an important role in electric forklifts and various industrial equipment. It has a wide range of applications and provides key support for the stable operation and efficient operation of equipment.

Electric forklift drive control: responsible for managing the start, stop, acceleration, deceleration, and direction switching of the driving motor. Through precise control logic, it achieves a smooth and safe driving state for the forklift, meeting the mobility needs of different operating environments.

Hydraulic system management: Coordinate the actions of hydraulic pumps and solenoid valves, accurately control the lifting, tilting, and lateral movement of forks, ensure that goods can move accurately as expected during loading, unloading, and handling, and improve operational efficiency.

Operation signal acquisition and processing: Receive the operation signals sent by the driver from the handle, pedal, and button, and quickly convert these signals into execution instructions to ensure the accuracy of the operation and the timeliness of the response, achieving seamless connection between the driver's operation intention and the device action.

Safety monitoring and protection: Real time monitoring of the status of batteries, motors, and various sensors. Once abnormal conditions such as overload, overvoltage, overcurrent, and limit are detected, the protection mechanism can be triggered immediately, effectively improving the safety of the operation process and reducing the risk of equipment damage.

Auxiliary equipment control: Control the lighting, buzzer, display panel and other auxiliary devices of the forklift. The lighting provides clear illumination when the light is insufficient, the buzzer issues a warning during critical operations, and the display panel provides real-time feedback on the equipment's operating status, thereby optimizing the convenience and safety of operations.

Fleet management and maintenance: Support the collection and fault diagnosis of equipment operation data, which provides a strong basis for developing scientific and reasonable maintenance plans and efficient operation management, helping to extend the service life of equipment and reduce operation and maintenance costs.

Application of industrial automation equipment: In addition to electric forklifts, it can also be extended to automated handling vehicles, stackers, and other industrial vehicles that require centralized control of drive and hydraulic systems, providing stable and reliable control support for industrial automation production.

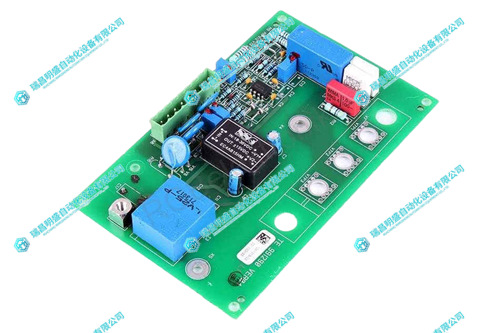

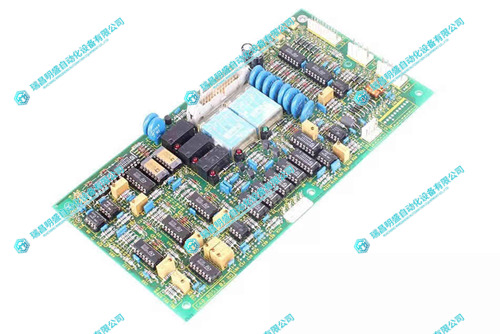

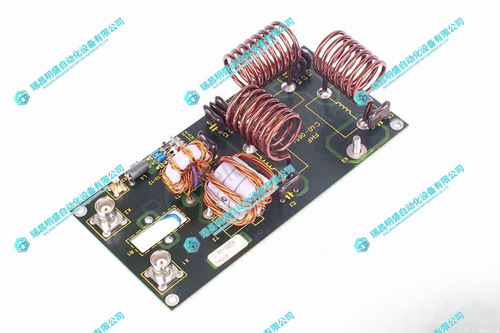

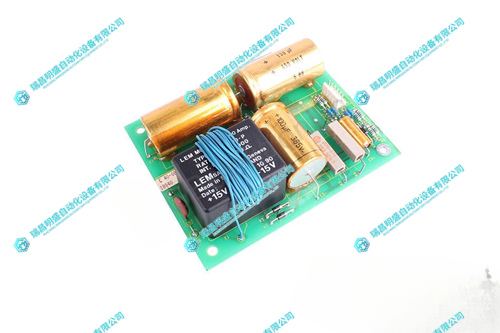

2.产 品 展 示

3.其他产品

REXROTH PPC-R22.1N-T-NN-P1-NN-FW 伺服控制器

4.其他英文产品

ABB P8840 8-channel temperature module

HONEYWELL TK-FTEB01 51309512-175 Bridge

RADISYS 61-0159-03 CPU circuit board

| AMAT 0190-43437 | AMAT 0190-81158 | AMAT 0190-10204 |

| AMAT 0190-18138 | AMAT 0190-81245 | AMAT 0190-10205 |

| AMAT 0190-39904 | AMAT 0190-81774 | AMAT 0190-10219 |

| AMAT 0190-13806 | AMAT 0190-81898 | AMAT 0190-10238 |

| AMAT 0190-15759 | AMAT 0190-81899 | AMAT 0190-10239 |

| AMAT 0190-09437 | AMAT 0190-81900 | AMAT 0190-10243 |

| AMAT 0190-22204 | AMAT 0190-81901 | AMAT 0190-10304 |

Contact: +86 15270269218