GIDDINGS & LEWIS 401-56453-50交流伺服驱动器

1.产 品 资 料 介 绍:

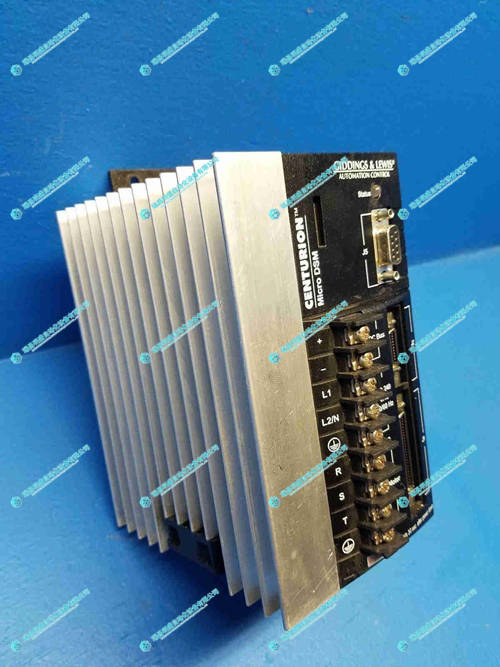

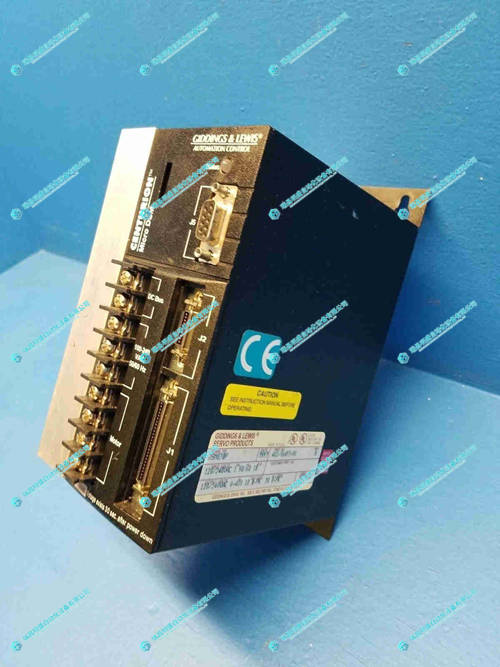

GIDDINGS & LEWIS 401-56453-50 交流伺服驱动器概述

英文资料:

GIDINGS&LEWIS 401-56453-50 AC Servo Drive Overview

GIDINGS&LEWIS 401-56453-50 AC servo drive is an industrial grade high-performance drive unit designed specifically for use with brushless AC servo motors, enabling precise speed, position, and torque control. With its fast response speed, stable operation, and complete protection functions, it has demonstrated its capabilities in fields such as CNC machine tools, automated production lines, and robot systems, providing precise motion control and efficient energy conversion for equipment. It is a key component in industrial automation control.

In terms of technical specifications, the driver performs outstandingly. The input power supply supports industrial AC power input and has overvoltage, undervoltage, and phase sequence protection functions, which can effectively cope with power grid fluctuations and ensure the safe and stable operation of itself and connected equipment. In terms of output control, it can be adapted to brushless AC servo motors, supporting vector control and high-speed pulse response, which enables the motor to maintain good operating performance under various working conditions and achieve smooth and precise rotation.

The feedback interface is compatible with incremental/absolute encoder signals, and by receiving real-time feedback information on the position and speed of the motor, a reliable closed-loop control is constructed to further improve control accuracy. The control modes are flexible and diverse, supporting multi-mode switching of speed control, position control, and torque control. They can be quickly adjusted according to the needs of different application scenarios to meet diverse control requirements.

The protection function is very comprehensive, with automatic protection against overcurrent, overheating, short circuit, and overload. When the system encounters abnormal situations, it can quickly respond, cut off output or take corresponding protective measures, greatly improving the safety of the system and reducing the risk of equipment damage. In terms of communication capabilities, it supports communication with upper computers, PLCs, and GIDINGS&LEWIS control systems, facilitating centralized management and remote monitoring, and enhancing the integration and intelligence level of the entire industrial control system.

In application scenarios, this driver plays an important role. In the field of CNC machine tools, it is used for spindle and feed servo control, which can accurately control spindle speed and feed rate, achieve high-precision cutting and stable machining, and ensure the machining quality and accuracy of parts. In automated production lines, servo control is applied to the conveying system, sorting mechanism, and assembly equipment to ensure coordinated and synchronized actions of each device, thereby improving the operational efficiency and stability of the production line.

In industrial robot systems, it is responsible for joint drive and actuator control. With its fast response capability and high-precision motion control, it meets the motion requirements of robots in complex working environments, improving the accuracy and flexibility of robot operations. In packaging and printing machinery, rapid start stop, precise position control, and high-speed operation of equipment can be achieved to ensure the quality and efficiency of packaging and printing. In addition, in the textile and electronic manufacturing industries, it can be used for equipment such as winding machines and surface mount machines that require precise control and high-speed production, helping to improve production quality and efficiency.

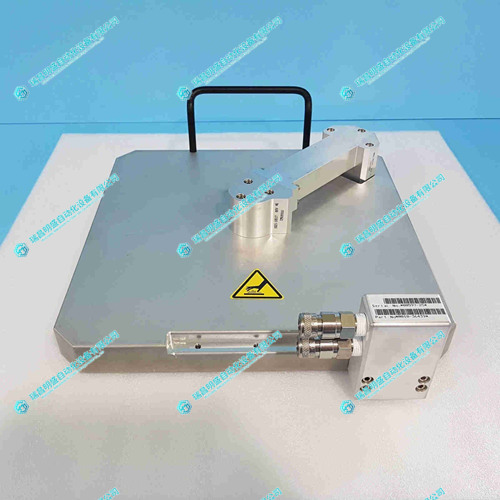

2.产 品 展 示

3.其他产品

4.其他英文产品

Kollmorgen MMC-SD-0.5-230-D servo drive

YT204001-KA/5 voltage signal regulator

| R46GENA-R2-NS-NV-00 | R32GENC-HS-ND-NV-00 | S33HSNA-RNNM-02 |

| R46GENA-R2-NG-VS-00 | R46GSNA-HS-NS-NV-03 | S31GNAA-RNNM-00 |

| R46GENA-HS-NS-NV-00 | R33GENT-TS-NS-NV-00 | R43GENA-R2-NS-NV-00 |

| R46GEBA-R2-NS-VS-00 | R45GENA-R2-NS-NV-00 | S21HNNA-RNN6-00 |

| R46GEBA-R2-NS-NV-02 | R22H5NA-R1-NS-NV-17 | R24SSNA-R1-NS-NV-03 |

Contact: +86 15270269218