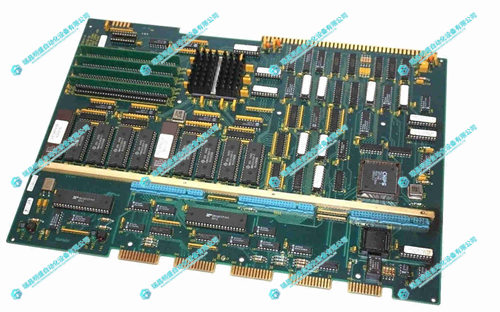

GIDDINGS & LEWIS 501-04708-00执行控制板

1.产 品 资 料 介 绍:

GIDINGS&LEWIS 501-04708-00 执行控制板

英文资料:

GIDINGS&LEWIS 501-04708-00 Execution Control Board

The GIDINGS&LEWIS 501-04708-00 execution control board is a core component in industrial automation control systems, responsible for connecting upper level control instructions with terminal execution devices. It plays an irreplaceable role in scenarios such as CNC machine tools, automated production lines, and intelligent warehousing.

From a functional perspective, the control board has efficient instruction processing and execution capabilities. It can receive real-time control signals from upper level systems such as PLCs and industrial computers, quickly analyze the meaning of instructions through internal logic operations, and then output accurate driving signals to executing devices such as motors, solenoid valves, servo drives, etc. For example, on an automobile assembly line, when the upper system issues the command to "tighten bolts", the control board will immediately calculate the speed, torque, and running time of the servo motor, drive the robotic arm to complete standardized operations, and ensure that the tightening accuracy of each bolt meets the process requirements.

In terms of technical characteristics, the 501-04708-00 control board demonstrates industrial grade reliability and flexibility. It is equipped with ARM 9 ™ Embedded processors have fast computing speed and can complete complex logic judgments in milliseconds, ensuring real-time response to dynamic production scenarios. The 5-key membrane keyboard and clear indicator light design allow operators to quickly perform parameter calibration, mode switching, and other operations without the need for professional programming knowledge to complete basic debugging. Rich interface configuration, not only supporting relay module expansion to increase switch control channels, but also equipped with external reset interface and pre alarm relay interface, which can be linked with temperature sensors, pressure transmitters and other devices. When abnormal data is detected, it will automatically trigger shutdown or alarm, improving system safety. In addition, through the list master/slave data interface, collaborative work of multiple control boards can be achieved to meet the distributed control requirements of large-scale production lines.

In application scenarios, the adaptability of this control board is very outstanding. In the field of CNC machine tools, it is responsible for coordinating the timing of spindle rotation, tool holder switching, and coolant injection to ensure a coherent and accurate cutting process; In automated production lines, synchronous control of conveyor belt start stop, sorting robotic arm movements, and quality inspection equipment operation can be achieved to reduce process connection errors; In the intelligent warehousing system, precise positioning and efficient transportation of goods are achieved by controlling the lifting motor and walking motor of the stacker crane; In the pump station of the energy industry, the pump speed can be automatically adjusted based on the pressure data of the pipeline network, balancing the water supply and energy consumption.

Overall, the GIDINGS&LEWIS 501-04708-00 execution control board, with its stable performance, flexible configuration, and wide adaptability, has become an important bridge connecting "decision-making" and "execution" in industrial automation control systems, providing a solid guarantee for improving production efficiency and process accuracy.

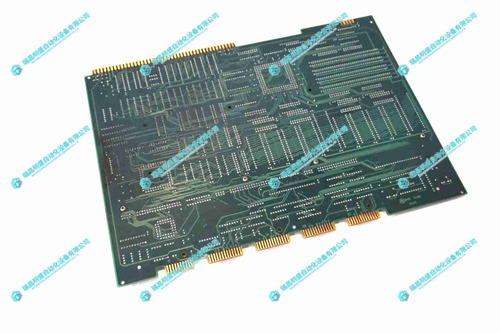

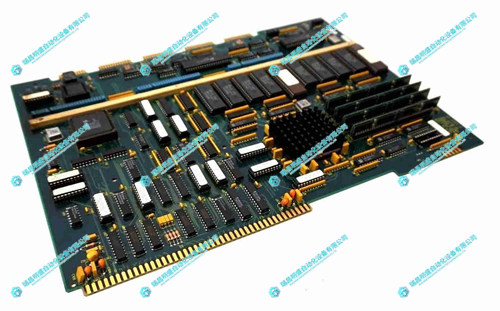

2.产 品 展 示

3.其他产品

4.其他英文产品

ABB P8480 Analog Output Module

Radisys EPC-3307 processor board

| PXIe-5630 | R32SSNA-R2-NS-NV-08 | S32HNAA-RNNM-00 |

| PXIe-5605 | R43HCNA-R2-NS-VS-00 | R34KSNP-R2-NS-NV-02 |

| PXIe-5601 | R33GENC-TS-ND-NV-00 | R43G0NA-R2-NS-VS-00 |

| PXIe-5540 | R43HEBA-R2-NS-VS-02 | R34JEBC-R2-NS-NV-00 |

| PXIe-5450 | R43HCNA-NP-RW-VS-00 | R43GENA-TS-M2-VS-02 |

| PXIe-5172 | R34JMNC-R2-NS-NV-00 | R43HEBA-TS-NS-NV-00 |

Contact: +86 15270269218