GIDDINGS & LEWIS DSM030伺服驱动器

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS DSM030 伺服驱动器概述

英文资料:

GIDINGS&LEWIS DSM030 Servo Drive Overview

GIDINGS&LEWIS DSM030 servo drive is a high-performance industrial motion control module, whose core function is to drive servo motors and achieve precise position, speed, and torque control. It supports closed-loop feedback control and can seamlessly cooperate with multi axis servo systems in CNC machine tools, industrial robots, and automated production lines. Its industrial grade design ensures stable operation in high load, vibration, and interference environments, making it an important equipment for achieving precise motion control in the field of industrial automation.

In terms of technical characteristics, the control mode of this driver is flexible and diverse, supporting closed-loop position, speed, and torque control. Through real-time feedback adjustment, it ensures the accuracy of servo motion and meets the control requirements under different working conditions. Outstanding multi axis drive capability, capable of driving single axis or multi axis servo motors, easily achieving complex trajectory motion, suitable for industrial scenarios with multi axis linkage.

Rich input/output interface configuration, providing digital/analog interfaces, supporting encoder feedback and limit signals, can smoothly connect with various sensors, controllers and other devices, and build a complete control loop. High speed response is its significant advantage, which can quickly process control instructions, make motor motion smooth and high-precision, and improve the dynamic performance and control accuracy of equipment.

The safety protection mechanism is complete, with overcurrent, overload, over temperature, and short circuit protection functions. It can respond promptly in case of system abnormalities, ensuring the safe operation of the driver, motor, and the entire system. Strong industrial adaptability, with characteristics of anti vibration, high temperature resistance, and anti electromagnetic interference, it can work continuously and stably in harsh industrial environments without being affected by environmental factors. The modular installation design is compact, facilitating system integration and maintenance, reducing installation space requirements and later maintenance costs.

In the field of CNC machine tools, it controls the spindle and multi axis feed to achieve high-precision machining and linkage control, ensuring the machining quality and accuracy of parts; In automated production lines, drive conveying, assembly, sorting and other equipment to ensure synchronous operation of each device and improve production efficiency; In industrial robot systems, controlling robot joints and end effectors enables multi task collaboration and complex actions, enhancing the flexibility and accuracy of robot operations; In terms of packaging and printing equipment, precise driving of feeding, cutting, and positioning mechanisms improves operational accuracy and speed, ensuring product quality; In the experimental and testing platform, precise control and data acquisition of the servo motor-driven experimental device are carried out to ensure the accuracy and reliability of the experimental data.

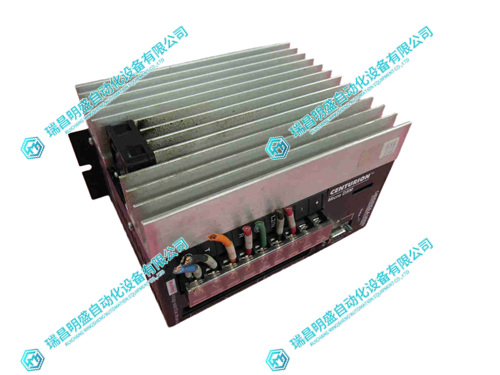

2.产 品 展 示

3.其他产品

4.其他英文产品

ASEA E-31709 Robot Circuit Board

IS200EPSMG1ABB Analog Input Module

| PMB33F-10101-01 | 70BV05A-E | R22HMNA-R1-NS-NV-01 |

| PMB33F-10101-00 | 70SL05A | R45GSNA-R2-NS-NV-03 |

| PMB33F-10100-03 | DT 370a | R43HCNA-NP-RW-VS-03 |

| PMB33F-10100-02 | ABB DSAO120A 3BSE018293R1 | R32GEAP-R2-NS-VS-00 |

| PMB33F-10100-01 | DC 371a | R33GENT-TS-NS-NV-03 |

Contact: +86 15270269218