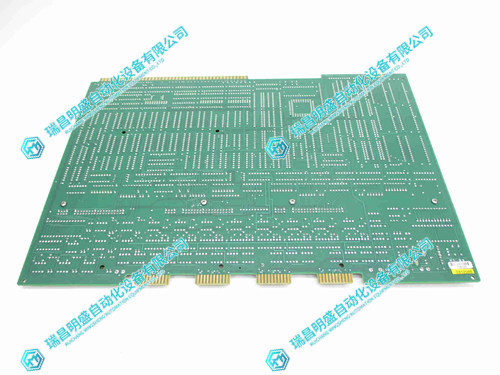

GIDDINGS & LEWIS 502-03417-02处理器模块

1.产 品 资 料 介 绍:

GIDDINGS&LEWIS 502-03417-02 处理器模块 — 产品应用领域

一、核心工业控制场景

二、智能制造与工业物联网

三、特种装备与流程工业

四、定制化自动化系统

英文资料:

GIDDINGS&LEWIS 502-03417-02 Processor Module - Product Application Fields

1、 Core industrial control scenarios

As the core processing unit in the field of industrial automation, this processor module plays a central role in multiple critical scenarios with high-performance data processing capabilities and stable control logic

Heavy Machinery Automation: A control system suitable for large rolling mills, forging equipment, and other heavy machinery, responsible for processing real-time data during equipment operation (such as pressure, torque, displacement, etc.), adjusting equipment operating parameters through precise calculations, and ensuring the stability and safety of heavy machining processes.

Precision manufacturing equipment: In high-precision devices such as semiconductor packaging equipment and precision measuring instruments, it undertakes control instruction calculations at the micrometer or even nanometer level, coordinates the synchronous actions of various components of the equipment, and ensures the accuracy of precision operations.

2、 Intelligent Manufacturing and Industrial Internet of Things

Smart factory data hub: as the edge computing node of the smart factory, it can collect the operation data (such as energy consumption, capacity, fault information, etc.) of various equipment in the production line in real time, and upload the key data to the cloud management platform after localized analysis and processing, so as to provide data support for production optimization and decision-making.

Equipment networking and collaborative control: Supports multiple industrial communication protocols (such as Profinet, EtherCAT, etc.), enabling collaborative control between multiple devices and production lines. For example, in automotive welding production lines, coordinating the linkage of welding robots, conveying equipment, and detection devices to improve overall production pace.

3、 Special Equipment and Process Industry

Ship and ocean engineering equipment: applied to ship power control systems, ocean platform drilling equipment, etc., in complex marine environments (such as salt spray, vibration, high and low temperatures), to stabilize the operating parameters of equipment and ensure the safety of navigation or operations.

Energy and Public Utilities: Responsible for real-time monitoring of key parameters (such as temperature, pressure, and flow) in power generation equipment (such as steam turbines and generator sets) and water treatment systems, adjusting equipment operating status through closed-loop control algorithms to achieve efficient energy utilization and environmental standards.

4、 Customized automation system

Non standard automated production line: For customized special production lines (such as aerospace component assembly lines, medical equipment production lines), this module can flexibly adapt to customized control logic, process diverse input and output signals, and meet the control needs of personalized production processes.

Upgrading and retrofitting of old equipment: In the intelligent upgrading project of industrial equipment, as the core component to replace old processors, it is compatible with the interfaces and communication methods of traditional equipment, improves the computing speed and control accuracy of equipment, and extends the service life of equipment.

2.产 品 展 示

3.其他产品

4.其他英文产品

RADISYS 061-05927-0031 adapter module

KOLLMORGEN S70602-NANANA servo/driver

ASEA ES1530b module card board

| PMB33E-00100-01 | AIN300 | 3BSE003859R1 DSDX 180 |

| PMB33E-00100-00 | NTCF03 | P22NSXA-LDN-NS-02 |

| PMB33C-20216-03 | AMAT 0100-09084 | PFTL101AE 2.0KN 3BSE004213R1 |

| PMB33C-20216-02 | 07BE61R1 | XV7713b |

| PMB33C-20216-01 | NASM02 | N32HRLK-LNK-NS-00 |

| PMB33C-20216-00 | PHKRMPBA2000A | P21NRXB-JNF-NS-00 |

Contact: +86 15270269218