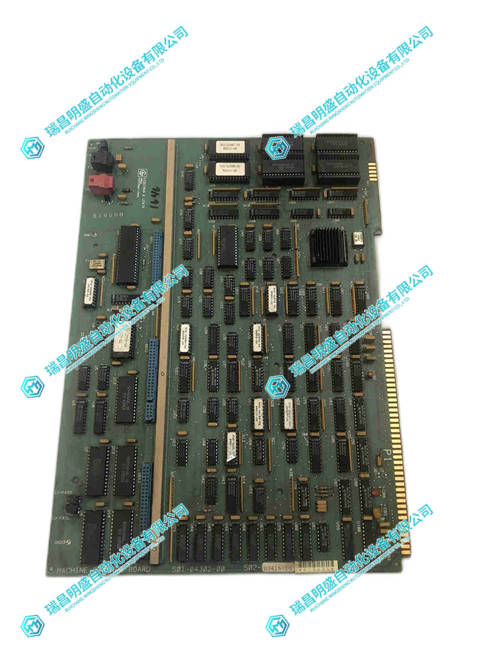

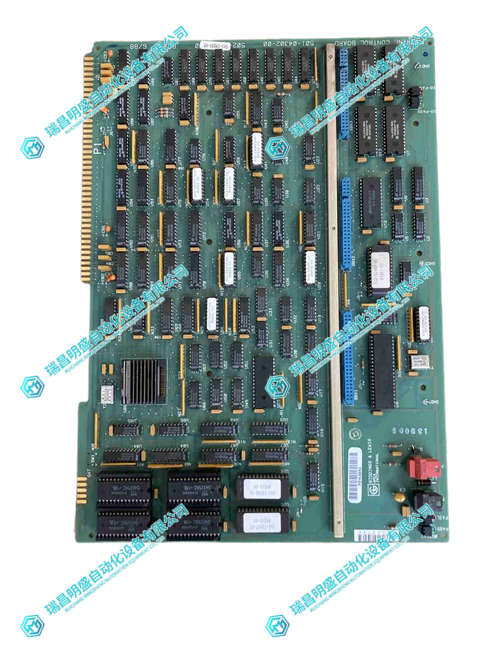

GIDDINGS & LEWIS 501-04302-00输入电路板

1.产 品 资 料 介 绍:

一、产品概述

二、产品特点

三、应用场景

英文资料:

1、 Product Overview

The GIDINGS&LEWIS 501-04302-00 input circuit board is the core signal acquisition module in industrial automation systems, specifically responsible for receiving raw signals from sensors, switches, and other input devices, and converting them into a standard format recognizable by the control system, providing real-time and reliable data support for the precise operation of automation equipment. This module is widely used in scenarios such as CNC machine tools, automated production lines, and industrial robots, and is a key bridge connecting the underlying perception equipment with the upper control system.

2、 Product Features

Multi channel signal acquisition: Integrating multiple digital and analog input interfaces, it can synchronously collect various types of sensor signals such as temperature, pressure, and position, meeting the multidimensional data requirements of complex industrial scenes.

Signal optimization processing: Equipped with professional filtering circuits and anti shake algorithms, it can effectively filter out noise such as electromagnetic interference and mechanical vibration, ensuring the stability and accuracy of collected data.

Strong system compatibility: Seamless integration with G&L series processor modules, main controllers, and other I/O components, simplifying system integration processes and reducing compatibility risks.

Real time response capability: Using high-speed signal processing chips, it can quickly capture instantaneous signal changes and complete conversion, ensuring timely triggering and execution of control instructions.

Industrial grade durability: Designed with anti vibration structure, it can withstand a wide temperature range of -20 ℃~70 ℃, has strong electromagnetic compatibility, and can operate stably in complex workshop environments such as dust and oil pollution for a long time.

Modular design: Standardized installation dimensions and interfaces for quick disassembly, on-site debugging, and later functional expansion, reducing maintenance downtime.

3、 Application scenarios

In the field of CNC machine tools, precise collection of limit switch signals, tool position sensor data, and spindle/feed axis encoder signals is provided to provide real-time position feedback for closed-loop control, ensuring the dimensional accuracy and surface quality of precision machining.

Automated production line: receiving signals from sensors, material detection switches, safety gratings and other equipment at the workstation, realizing automatic start stop, process switching and abnormal shutdown protection of the production process, and improving the collaborative efficiency of the production line.

Industrial robot system: Obtain robot joint angle sensors, end effector force feedback signals, and workspace safety sensor data for motion trajectory correction, collision protection, and optimization of work accuracy.

Packaging and Printing Machinery: Collecting data from feeding speed sensors, paper positioning signals, and quality inspection devices to achieve material tension control, overlay accuracy adjustment, and automatic waste removal, improving the consistency and pass rate of packaging printing.

Experimental and testing platform: In industrial equipment development or performance testing scenarios, real-time collection of various physical quantity signals from experimental devices provides high-precision data support for control algorithm validation and equipment performance evaluation.

2.产 品 展 示

3.其他产品

4.其他英文产品

ASEA ES1530b module card board

3BHE009681R0101 GVC750BE101 thyristor hi

| PMB33C-20201-00 | IPCHS01 | PFTL101AER 0.5KN 3BSE023010R1 |

| PMB33C-20200-03 | 07PT40 | 57120001-LK DSTY 110 |

| PMB33C-20200-02 | 07AB90-S | N43HRFM-LNK-NS-00 |

| PMB33C-20200-01 | ECZ | 57120001-U DSAI 150 |

| PMB33C-20200-00 | NKLS020 | PFTL101BER 20.0KN |

| PMB33C-20116-03 | AMAT 0100-09058 | M22NRXA-JDF-M1-00 |

Contact: +86 15270269218