GIDDINGS & LEWIS 502-03549-02输出模块

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS 502-03549-02 输出模块应用领域及价值解析

一、核心应用领域

数控机床控制系统领域

多轴自动化生产线领域

工业机器人系统领域

包装与印刷设备领域

纺织与卷绕机械领域

英文资料:

Application Fields and Value Analysis of GIDINGS&LEWIS 502-03549-02 Output Module

1、 Core application areas

In the field of CNC machine tool control systems

As a key output interface connecting the controller and the actuator, it directly drives the speed adjustment of the spindle motor, displacement control of the feed shaft, and tool changing action of the tool magazine. In the machining center, precise pulse signals can be output to control the micrometer level movement of the feed axis, while triggering the rotation of the tool magazine and tool clamping through logical signals to ensure the timing accuracy of the automatic tool changing process (tool changing time ≤ 2 seconds), meeting the continuous machining needs of precision parts.

Multi axis automated production line field

Control the joint movements of the assembly robotic arm, the start stop and speed adjustment of the conveyor belt, and the action logic of the workstation actuators (such as push rods and clamping devices). On the automotive parts assembly line, multiple control signals can be synchronously output to coordinate the processes of mechanical arm grasping, conveyor line transportation, and press fitting of the press fitting machine, ensuring that the time difference between each action is ≤ 0.5 seconds and improving the production line's cycle efficiency.

In the field of industrial robot systems

Drive the actions of robot end effectors (such as welding guns, gripping fixtures), as well as the movement of auxiliary mechanisms (such as positioners, guides). In the welding robot workstation, analog signals can be output to control the swing amplitude and speed of the welding gun. At the same time, digital signals can be used to control the opening and closing of the fixture, which can be combined with the joint motion of the robot to achieve precise welding of complex welds.

Packaging and printing equipment field

Output control signals to drive the speed of the feeding motor, the start and stop of the cutting tool, the heating and pressurization of the packaging device, and the phase adjustment of the printing drum. In high-speed food packaging machines, the matching between film feeding speed and cutting frequency can be adjusted through pulse signals to ensure a production rate of 300+packages per minute and a packaging size error of ≤ 1mm. At the same time, stable output of heat sealing temperature can be controlled to ensure sealing quality.

Textile and winding machinery field

Control the speed of the winding motor, the action of the tension adjustment device, the drive of the feeding system, and the operation of auxiliary equipment such as cleaning devices and slitting mechanisms. In the chemical fiber winding machine, a variable frequency signal can be output to adjust the winding speed, and feedback from the tension sensor is used to achieve closed-loop control, so that the yarn winding density deviation is ≤ 3%, reducing problems such as loose yarn and broken yarn.

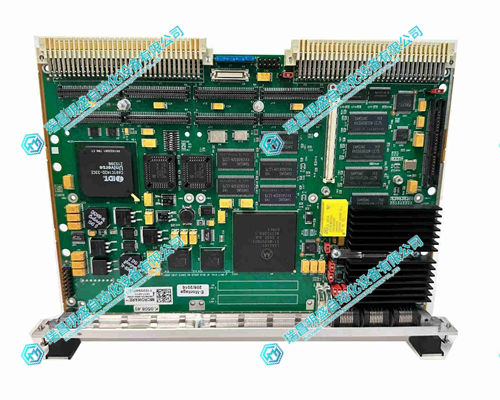

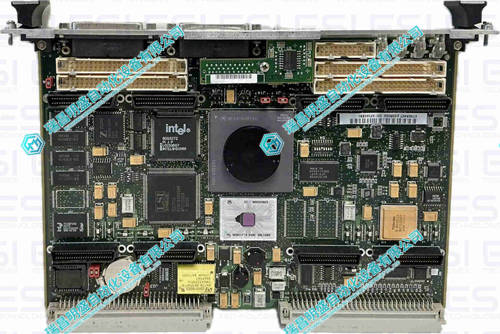

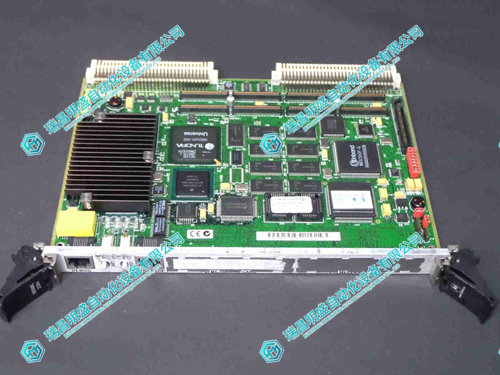

2.产 品 展 示

3.其他产品

4.其他英文产品

Kollmorgen MMC-SD-0.5-230-D servo drive

REXROTH PPC-R22.1N-T-NN-P1-NN-FW servo

DELTA TAU ACC-24E2 interface simulation

| PETL101AE | AMAT 0100-77063 | MC-TD0Y23 |

| PEEL112 | AMAT 0100-02485 | MC-PAIH03 |

| PCE845-XYZ-T | AMAT 0100-03622 | MC-TAMT03 |

| PCE845-XYZ-N | AMAT 0100-91086 | MC-TAMR04 |

| PCE845-XYZ-F | AMAT 0100-09068 | MC-TAMR03 |

| PCE845-XYZ-A | AMAT 0100-03378 | MC-TAIH14 |

| PCE843-001-T | AMAT 0100-20335 | MC-TAIH13 |

Contact: +86 15270269218