GIDINGS&LEWIS 502-02777-50数字化控制板

1.产 品 资 料 介 绍:

产品概述

技术参数

英文资料:

Product Overview

In the field of industrial automation and numerical control systems, the Giddings&Lewis 502-02777-50 digital control board can be regarded as a key core component. It is like the "smart brain" of the entire system, fully responsible for data processing, instruction logic operations, and digital fine management of external interfaces. Whether in complex and precise CNC systems, motion controllers with extremely high requirements for motion accuracy, or various large and complex production equipment, this control board plays an irreplaceable core role. Through the high-speed bus, it can achieve efficient and stable communication with other functional modules, thereby realizing centralized and precise management of servo drives, I/O modules, and actuators, ensuring the coordinated and smooth operation of the entire industrial automation system.

Technical Specifications

Product type: Professional digital control board, tailored for industrial automation and CNC application scenarios.

Core functions:

Accurately execute logical operations, quickly parse and process various control instructions.

Ordered scheduling of system program execution ensures the smooth operation of the system.

Efficiently manage signal transmission and achieve precise signal transmission and reception between different modules.

Processing capability: With powerful processing performance, it can support high-speed logic control and data processing. The specific clock frequency will be flexibly adjusted according to the system configuration to adapt to the differentiated processing speed requirements of different application scenarios. Whether it is simple tasks or complex operations, it can be easily handled.

Interface features:

Equipped with rich interfaces, it can easily connect to I/O modules to achieve flexible acquisition and output control of input and output signals.

It can seamlessly integrate with the servo drive module to provide precise control signals for the servo motor, ensuring the accuracy of equipment movement.

Supports connection with multiple communication interfaces, facilitating data exchange with other devices or upper computers, achieving remote monitoring and system integration.

Having multi-channel data acquisition and output functions, it can simultaneously process multiple signals, greatly improving system operation efficiency.

Data processing: Equipped with advanced real-time task scheduling function, it can allocate system resources reasonably based on task priority and time requirements, ensure stable and efficient operation of control loops, and ensure timely and accurate response of the system to various signals and instructions.

Power supply requirements: Powered by a+5V DC logic power supply, the typical operating current will be in the range of several hundred mA according to the actual system configuration. The power supply requirements are reasonable, and the energy consumption control is excellent, effectively reducing system power consumption while ensuring stable operation.

Work environment:

The temperature adaptation range is from 0 ° C to 55 ° C, and it can operate stably in most conventional industrial environments without the need for additional complex temperature control measures.

The humidity adaptation range is 5% to 95% (without condensation), which can withstand a certain degree of humid environment, reduce the risk of failure caused by humidity problems, and ensure long-term stable operation of the equipment.

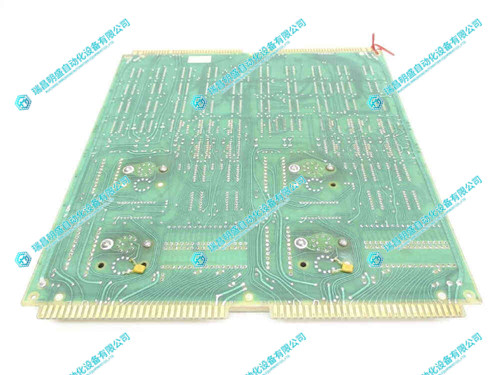

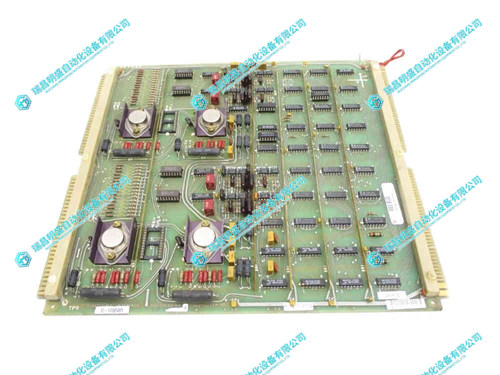

2.产 品 展 示

3.其他产品

4.其他英文产品

DS200TCEAG1BNE emergency overspeed board

| 6RA2218-6DV62-0 | 03-032257-00 | 720-20337-001 |

| 6RA2190-4DV60-6DB0-ZA07 | 03-166293-00 | F31X139APMALG2 |

| 6RA2190-4DV60-4JB0-ZA07 | 193X803BGG03 | F31X100CCHBCG1 |

| 6RA2116-6DV60-6DB0-ZA07 | 531X112PSAAMG1 | F31X134EPRBDG1 |

| -6GC11 | 193X803BEG03 | F31X134EPRBAG1 |

| 6ES5998-8MB22 | 531X116SHAAAG1 | 531X308PCSAEG3 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218