GIDINGS&LEWIS 502-03677-00步进模块

1.产 品 资 料 介 绍:

产品概述

产品应用领域

英文资料:

Product Overview

GIDINGS&LEWIS 502-03677-00 stepper drive module is the "precision control core" of stepper motors. It receives pulse signals from the central controller, converts them into motor rotation angles and step action commands, achieves high-precision control of position, speed, and direction, and provides stable driving support for precision motion of CNC machine tools and automation equipment, avoiding machining or operation errors caused by action deviations.

Product application areas

Numerical Control Machine Tool (CNC)

Control the feed axis to achieve small displacement adjustment (such as millimeter level feed), precise tool positioning (such as tool alignment during drilling), and can also cooperate with multi axis linkage to complete complex machining paths (such as surface carving). By high-precision step control, machining errors are reduced, component size accuracy is ensured, and precision machining requirements are met.

Automatic production line

Drive the conveyor belt to accurately adjust the conveying speed (such as matching the assembly rhythm), control the robotic arm to complete repetitive grasping/placing actions (such as electronic component assembly), or drive the positioning device to achieve precise alignment of the workpiece (such as fixing the workpiece before welding). By relying on stable repetitive operations, reducing manual intervention, and improving the automation efficiency of the production line.

Packaging and Printing Machinery

Control the feeding wheel to transport packaging materials/printing paper at a constant speed (to prevent packaging misalignment and inaccurate printing caused by feeding deviation), drive the scroll to accurately retract and release materials (to maintain stable material tension), adjust the positioning mechanism to ensure accurate alignment of packaging sealing and printing patterns. Ensure process stability, reduce material waste, and improve mass production quality.

robot system

For small servo joints (such as micro robot arm joints) or end effectors (such as precision grippers), achieve micro step motion control (such as micro level gripping force adjustment, small angle rotation). Ensure precise movements of the robot during fine operations such as chip assembly and small part handling to avoid damaging the workpiece.

Experimental and testing platform

Used for precision positioning experimental devices (such as optical component adjustment tables) and testing tables (such as load positioning for motor performance testing), ensuring that experimental actions can be repeated through stable step control (such as minimal positioning errors multiple times), providing reliable experimental data for researchers, and helping to analyze process parameters and system performance.

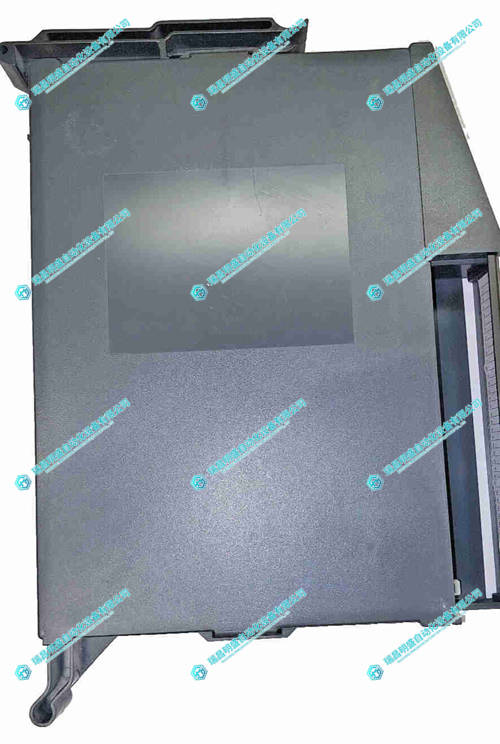

2.产 品 展 示

3.其他产品

4.其他英文产品

Atlas Copco PF3007-C-HW Torque Controlle

Atlas Copco PF3007-G-DN-HW Controller

Atlas Copco PF3007-C-HW Torque Controlle

| 6AV35151MA201AA0 | 6DD1681-0CD0 | TRICONEX 3503E |

| 6AV30101DK00 | 6DD1681-0BF1 | TRICONEX 3700 |

| 6415-001-N-N-N | 6DD1681-0BD1 | TRICONEX 3700A |

| 6415-001-N-N-K | 6DD1681-0AJ2 | TRICONEX 3701 |

| 6415-001-N-H-K | 6DD1681-0AJ1 | TRICONEX 3703E |

| 6415-001-G-N-K | 6DD1681-0AJ0 | TRICONEX 3604E |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218