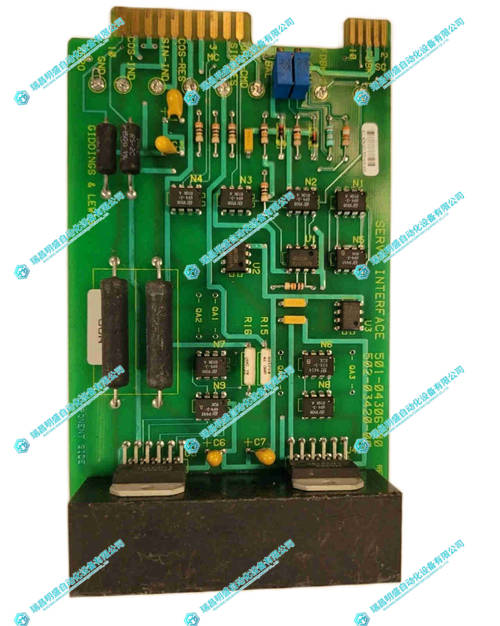

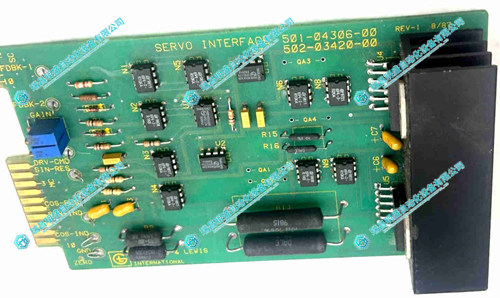

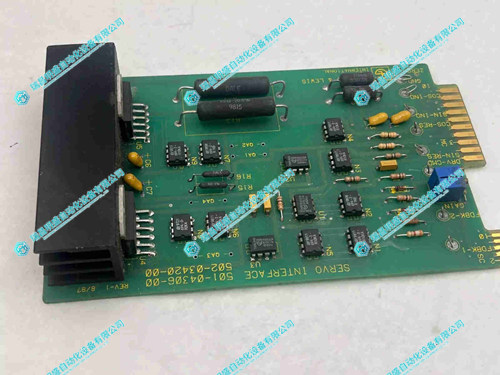

GIDINGS&LEWIS 502-03420-00 伺服接口模块

1.产 品 资 料 介 绍:

Giddings & Lewis 502-03420-00 伺服接口模块介绍

一、产品概述

二、产品特点

(一)多轴支持

(二)闭环控制能力

英文资料:

Introduction to Giddings&Lewis 502-03420-00 Servo Interface Module

1、 Product Overview

The Giddings&Lewis 502-03420-00 servo interface module is a key core module in the PiC series control system that realizes "instruction transmission and feedback closed-loop". It can be regarded as the "intelligent translator" and "data hub" between the servo system and the control system. Its core function lies in bidirectional signal processing: on the one hand, it accurately receives motion commands (such as position, speed, torque commands) issued by the control system, and converts them into control signals that can be directly recognized by the servo drive through internal signal conversion circuits; On the other hand, real-time feedback signals from servo motors (such as position and speed feedback) are collected, processed, and transmitted back to the control system to form a complete closed-loop control loop.

In the high-precision motion control scenario of industrial automation, this module is the core support for achieving multi axis collaboration and precise control. Whether it is high-precision machining of CNC machine tools or linkage control of multi axis motion systems, it can ensure that there is no delay in instruction transmission and no deviation in feedback data, providing a solid guarantee for the high-performance operation of industrial equipment.

2、 Product Features

(1) Multi axis support

Multi drive collaboration: The module has the ability to simultaneously connect multiple servo drives and can support up to multi axis synchronous control (the specific number of axes depends on the system configuration). In multi axis motion scenarios, such as multi axis linkage CNC machine tools and industrial robots, modules can uniformly receive multi axis motion commands from the control system and transmit them to corresponding servo drives, ensuring that multiple motors start, run, and stop synchronously, avoiding machining errors or equipment failures caused by inter axis motion delays, and achieving efficient multi axis collaborative control.

Multi type equipment adaptation: compatible with multiple types of servo motors (such as AC servo motors, DC servo motors) and feedback devices, including incremental encoders, absolute encoders, etc. For example, when combined with an incremental encoder, it can collect real-time pulse signals of motor rotation and calculate motor position and speed; When working with an absolute encoder, it can directly read the absolute position information of the motor without the need for zeroing operation, improving the efficiency of equipment startup. This compatibility greatly reduces the difficulty of device selection and can flexibly adapt to servo systems of different brands and specifications.

(2) Closed loop control capability

Full dimensional closed-loop coverage: The module receives position, velocity, and torque signals feedback from the servo driver, compares them in real-time with the target instructions issued by the control system, dynamically adjusts the control signals output to the driver, and achieves triple closed-loop control of position, velocity, and torque. In position closed-loop control, the positioning error can be controlled at the micrometer level to meet the precision machining requirements of parts; Speed closed-loop control can effectively suppress the impact of load fluctuations on motor speed and maintain speed stability; Torque closed-loop control can accurately control the output torque of the motor, adapting to scenarios such as material clamping and tension control.

High precision and fast response: With optimized closed-loop control algorithms and high-speed signal processing capabilities, the module has excellent high-precision motion control and fast response performance.

2.产 品 展 示

3.其他产品

4.其他英文产品

HONEYWELL 05704-A-0146 Digital

1TGE120011R1111 Controller Module

PROSOFT MVI46-MCM communicatio

| SR3642-4822-84-7-48C-CU | SE10000-000000 | PFBL141B/C |

| SR3642-4822-7-CU | AMAT 0100-09017 | IMHSS03 |

| SR3642-4822-7-56HC-CU | AMAT 0100-35057 | 57310290-BY DSIH70 ABB |

| SR3642-4822-7-56BC-CV | AMAT 0100-00062 | 26390582-BR DSTK127 ABB |

| SR3642-4822-7-56BC-CU | AMAT 0100-76295 | 57310255-AL DSRF182 ABB |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218