GIDINGS&LEWIS 871-20695-01 控制器模块

1.产 品 资 料 介 绍:

Giddings & Lewis 871-20695-01 控制器模块介绍

一、产品概述

二、产品特点

(一)高性能处理能力

(二)多轴运动控制功能

英文资料:

Introduction to Giddings&Lewis 871-20695-01 Controller Module

1、 Product Overview

The Giddings&Lewis 871-20695-01 controller module is the "core command center" in the PiC series and compatible control systems, and can be called the "brain" of industrial automation equipment. Its core responsibilities cover three key areas: firstly, executing complex digital logic operations, handling control logic such as equipment start stop and fault interlock; The second is to parse and execute motion instructions, accurately scheduling multi axis motion trajectories and action timing; The third is to comprehensively manage input/output signals and coordinate data exchange between sensors, encoders, and actuators.

In CNC machine tools, multi axis automation equipment, and industrial control systems, this module directly determines the operating accuracy, response speed, and reliability of the system through efficient signal processing and instruction issuance. It is the core control unit that ensures the precision and automation of industrial production.

2、 Product Features

(1) High performance processing capability

Industrial grade computing power support: integrates high-performance CPUs designed specifically for industrial scenarios, with high-speed logical operations and multitasking parallel processing capabilities. In terms of logical operations, it can quickly parse complex control logic (such as multi condition interlock protection, production process judgment), ensuring that the equipment responds to external signals in milliseconds; In multitasking, it can synchronously schedule tasks such as motion control, I/O signal management, and data acquisition. For example, during CNC machining, it can simultaneously process tool position calculation, spindle speed adjustment, and machining progress monitoring, avoiding response delays caused by task queues and greatly improving the overall efficiency of the system.

Efficient processing of complex instructions: With powerful computing power, it can easily handle multiple motion control instructions and process logic requirements. For example, in multi axis linkage machining, interpolation operation instructions can be quickly processed to generate smooth motion trajectories; In automated production lines, multi station collaborative logic can be synchronously processed, and the actions of the next station can be dynamically adjusted based on feedback from the previous station to meet flexible production needs.

(2) Multi axis motion control function

Multi axis collaborative control: supports multi axis synchronous control and interpolation calculation, which can achieve speed synchronization, position synchronization, or torque synchronization of multiple motors. For example, in the drive of multiple conveyor belts in an automated production line, ensure that the speed of each conveyor belt is consistent to avoid material accumulation; In multi axis robot control, the robot is driven to complete complex trajectory actions through interpolation operations (such as line, arc, spiral interpolation, etc.), meeting the requirements of precision assembly, welding, etc.

Diversified motion modes: capable of point-to-point positioning (such as manually adjusting equipment position), continuous motion (such as long-distance linear machining), and complex path planning control. Simultaneously supporting acceleration and deceleration curve planning (trapezoidal, S-shaped acceleration and deceleration), avoiding the impact of sudden speed changes on equipment, reducing mechanical wear, improving motion stability, and adapting to the motion control needs of different industrial scenarios.

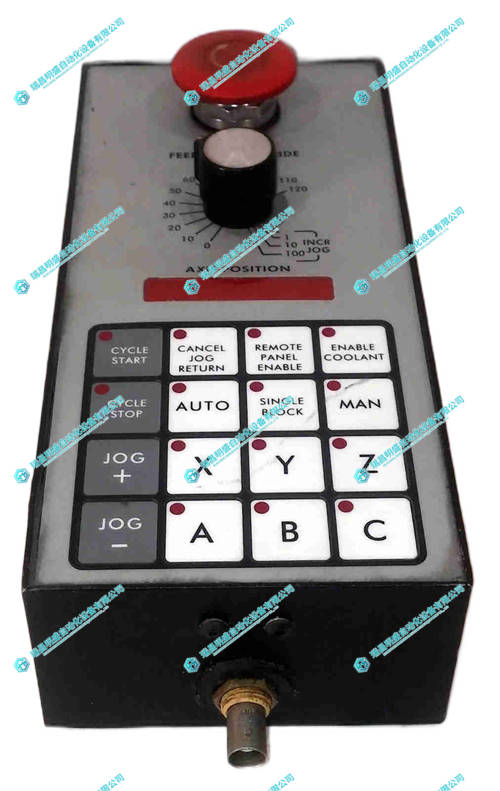

2.产 品 展 示

3.其他产品

4.其他英文产品

IS400JPDHG1ABB IS410JPDHG1A Feedback Sen

ASEA DSQC100 connector backplane

ASEA 2668 184-447 Communication Module

| RDIOR420 | SC323A-001 | SC104-001-T3 |

| RDIOR400 | SC402-010 | SC105010I3 |

| RCU510 | SC403-002-T3 | SC104-001-M |

| RCU502 | SC322A-601-01 | SC105-001-M |

| RCU501 | SC402-001-T3 | SC103-010-T4 |

| RCU500 | SC102-010-T4 | S21GSAA-RNNM-02 |

| RAIC400 | SC403-001-T4 | SC104-001 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218