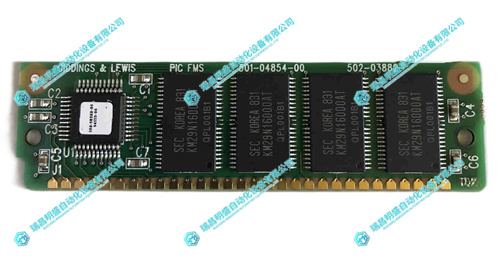

GIDINGS&LEWIS 501-04854-00内存系统模块

1.产 品 资 料 介 绍:

控制程序与配置存储

工艺数据缓存

固件与系统升级

数据备份与恢复

英文资料:

Control program and configuration storage

In the field of industrial automation, the GIDINGS&LEWIS 501-04854-00 memory system module plays a crucial role, especially in storing application programs for PLCs (Programmable Logic Controllers) or various control systems. These applications are like the "brain instructions" of automated systems, determining the system's operational logic and workflow. The module is responsible for storing both operational parameters and configuration data, such as key parameters such as production line operating speed and equipment start stop conditions. The non-volatile storage technology used ensures that data will not be lost after a power outage. When the system is powered on again, it can quickly call these programs and data, allowing the equipment to quickly recover to the working state before the power outage, greatly ensuring the continuity and stability of the production process, reducing production interruption time and economic losses caused by power outages, and widely used in continuous production industries such as metallurgy and chemical industry.

Process data cache

During the production process, this memory system module can serve as a cache unit for process parameters and intermediate states. In complex manufacturing processes, process parameters are constantly in dynamic changes, and intermediate states frequently change. For example, in the stamping process of automotive parts, process parameters such as pressure and temperature, as well as intermediate states such as shape changes of the workpiece during the stamping process, can be quickly cached by this module. Once the production process is interrupted due to unexpected circumstances, such as equipment failure, brief power outage, etc., the system can accurately restore to the correct operating position based on cached process data and restart the production process. This not only avoids a large amount of data loss and production process chaos caused by interruptions, but also greatly improves production efficiency, reduces scrap rates, and saves costs for the enterprise.

Firmware and system upgrade

The GIDINGS&LEWIS 501-04854-00 memory system module provides convenience in upgrading device firmware or control systems. With the continuous advancement of technology, the functionality of devices needs to be continuously updated and expanded, and firmware or control system upgrades are essential at this time. This module can be used to store firmware or control system upgrade files for devices. On site operators only need to store the upgrade files in the module to quickly update software versions. This process does not require complex external storage devices or network connections, greatly improving the convenience and efficiency of the upgrade. For example, in the upgrade of the control system of CNC machine tools, the control software can be quickly updated through this module to achieve new machining processes and functions, improve the machining accuracy and efficiency of the machine tool, and enable the equipment to better adapt to market demand and technological development trends.

data backup and recovery

As a backup medium for critical data, this memory system module has irreplaceable value in the event of a main controller or system failure. In industrial automation production, a large amount of production data, equipment operating parameters, and customer order information are crucial. The module is capable of regularly backing up this data, and can quickly restore the operating environment and parameters from the backup data in case of hardware failure of the main controller or software crash of the system. Taking the electronic manufacturing production line as an example,

2.产 品 展 示

3.其他产品

REXROTH PPC-R22.1N-T-NN-P1-NN-FW 伺服控制器

4.其他英文产品

GE D20 EME 10BASE-T Digital Control Modu

RADISYS 451558-004 Communication Module

ABB UN0942b-P Programmable Controller

| PMB33F-20216-00 | PM862K01 3BSE076940R1 | YPH107A 3ASD579001A9 |

| PMB33F-20214-03 | 3BSE003912R1 RF541 | 6DD2920-0AR2 |

| PMB33F-20214-02 | HONEYWELL 05701-A-0351 | AV43 AV 43 |

| PMB33F-20214-01 | MD032BNS | 6DD2920-0AR6 |

| PMB33F-20201-03 | ibp PCF 0512 J V234 T1 Z105键盘 | DSSR122 48990001-NK |

| PMB33F-20201-02 | HONEYWELL TC-CCN014 | ECC 086387-001 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218