GIDINGS&LEWIS M.1017.37722伺服驱动器

1.产 品 资 料 介 绍:

产品特点

1. 双轴控制能力

2. 高电流输出

3. 适配工作电压

4. 宽温工作范围

5. 模块化设计

6. 强兼容性

7. 诊断功能

应用领域

1. 数控机床(CNC)

2. 自动化生产线

3. 机器人控制系统

4. 包装和检测设备

5. 定制自动化设备

英文资料:

Product Features

1. Dual axis control capability

Support two axis servo synchronization or coordinated control, suitable for scenarios that require multi axis linkage (such as dual axis conveyor belts and multi axis assembly mechanisms), simplifying system wiring and control logic.

2. High current output

The maximum output current of each axis reaches 10 amperes, with sufficient power to drive high-power servo motors, meeting the stable driving requirements under heavy loads.

3. Adapt to working voltage

Supports 24 VDC operating voltage without the need for additional power conversion, suitable for most industrial electrical environments, and reduces system integration costs.

4. Wide temperature working range

The maximum environmental temperature tolerance is up to 55 ° C, and it can operate stably in high-temperature workshops (such as metallurgy and casting scenes) without being affected by environmental temperature fluctuations.

5. Modular design

Compact structure, can be flexibly combined with other control modules, supports system configuration and expansion as needed, and adapts to automation needs of different scales.

6. Strong compatibility

Seamlessly compatible with other modules of the PiC900 control system, it can be integrated without significant debugging and supports multiple industrial automation application scenarios.

7. Diagnostic function

Built in real-time status monitoring and fault alarm can provide troubleshooting guidance, quickly locate problems (such as overcurrent and overvoltage), and reduce maintenance time and downtime losses.

Application field

1. Numerical Control Machine Tool (CNC)

Drive the servo motor, respond to the instructions of the main controller to achieve precise movement of the machine tool axis, ensure high-precision cutting, milling and other machining requirements, and avoid machining deviations.

2. Automated production line

Realize multi axis coordinated control (such as synchronous conveyor belts and multi station assembly axes), improve production rhythm coherence, enhance production efficiency and product quality stability.

3. Robot control system

Provide precise driving for the joint axes of industrial robots, ensuring precise grasping, assembly, and other actions, reducing operational errors, and ensuring job safety.

4. Packaging and testing equipment

Drive the moving parts of the equipment (such as packaging sealing axis, detection platform moving axis) to achieve precise motion control, improve the automation level and operational efficiency of the equipment.

5. Customized automation equipment

Provide precise driving according to special scenario requirements, adapt to the multi axis control needs of non-standard equipment, and meet personalized industrial automation control requirements.

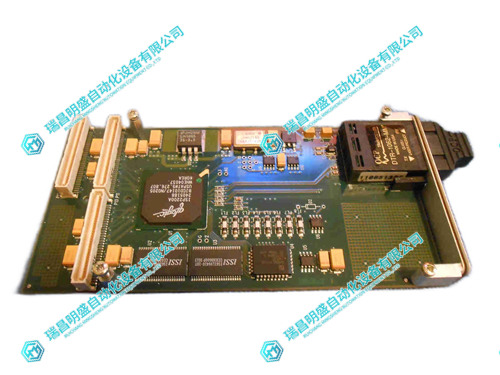

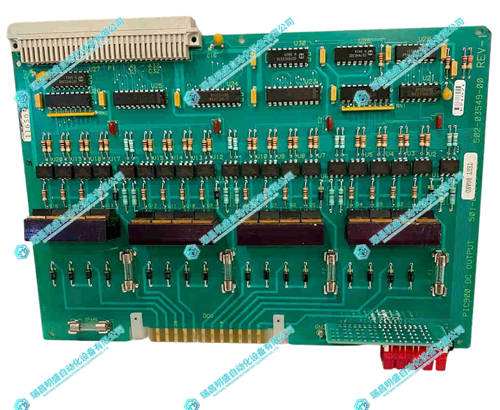

2.产 品 展 示

3.其他产品

KOLLMORGEN CP310250 PRD-P310250Z-55 伺服驱动器

4.其他英文产品

ABB P8840 8-channel temperature module

HONEYWELL TK-FTEB01 51309512-175 Bridge

RADISYS 61-0159-03 CPU circuit board

| PMB33E-00114-02 | AMAT 0100-00132 | M22NSXC-LSN-NS-03 |

| PMB33E-00114-01 | NKLS112 | PFCL301E 1.0KN 3BSE016580R1000 |

| PMB33E-00114-00 | AMAT 0100-00011 | N32HSHK-LNK-NS-02 |

| PMB33E-00101-03 | AMAT 0100-11000 | KT 8991a |

| PMB33E-00101-02 | NICS01 | P22NRXD-LNN-NS-02 |

| PMB33E-00101-01 | IIMKM01 | EHDB130 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218