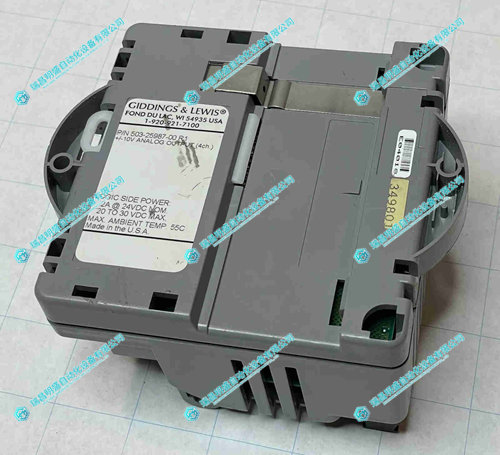

GIDINGS&LEWIS 503-25987-00 编码器模块

1.产 品 资 料 介 绍:

产品特点(推测)

1. 高分辨率反馈

2. 实时信号传输

3. 强抗干扰能力

4. 广泛兼容性

5. 模块化结构

6. 诊断功能

产品应用领域

1. 数控机床(CNC)

2. 自动化生产线

3. 机器人控制系统

4. 检测与测量设备

5. 定制工业设备

6. 电机控制系统

英文资料:

Product Features (Speculation)

1. High resolution feedback

It is speculated that it has high-resolution output and can accurately capture the small rotational displacement and velocity changes of the axis, providing precise data support for the control system and adapting to high-precision control scenarios.

2. Real time signal transmission

Support real-time output of position or velocity signals, meet closed-loop control requirements, help the system quickly adjust parameters, reduce control delays, and improve motion accuracy and stability.

3. Strong anti-interference ability

Adopting industrial grade protection design, it can resist temperature fluctuations, vibrations, and electromagnetic interference, maintain signal stability in complex industrial environments such as machine tool workshops and production lines, and avoid data distortion.

4. Wide compatibility

It is speculated that it is compatible with the Giddings&Lewis PiC900 control system, third-party servo drives, and frequency converters, and can be integrated without significant modifications, reducing system adaptation costs.

5. Modular structure

Compact design, easy to install in combination with other control modules, saves equipment space, and supports flexible system expansion to meet automation needs of different scales.

6. Diagnostic function

It may have built-in status monitoring and fault alarms, which can provide feedback on signal abnormalities and other issues, facilitating quick troubleshooting and reducing maintenance time and downtime losses.

Product application areas

1. Numerical Control Machine Tool (CNC)

Collect the rotational position and speed signals of the spindle and working axis, provide accurate feedback for the CNC control system, ensure the machining accuracy of cutting, milling and other processes, and avoid workpiece scrap due to positional deviation.

2. Automated production line

Detect the position and running speed of components in assembly lines and equipment, ensure the synchronization of actions at each workstation (such as the coordination between conveyor belts and assembly robotic arms), maintain production process stability, and improve production efficiency.

3. Robot control system

Provide precise position feedback for the joints and motion axes of industrial robots, assist the system in motion control and path planning, ensure precise grasping, assembly and other operations, and reduce safety risks.

4. Testing and measuring equipment

Used for position measurement and speed monitoring of rotating components such as detection platforms and measuring spindles, improving the accuracy and reliability of detection data and meeting high-precision measurement requirements.

5. Customized industrial equipment

Adapt to non-standard automation equipment that requires precise motion feedback, provide position or velocity signals according to special scenario requirements, and meet diverse industrial control requirements.

6. Motor control system

Cooperate with servo drives and frequency converters to achieve closed-loop control, adjust the motor operating status in real time, improve the motor speed accuracy and response speed, and ensure stable and efficient operation of the motor.

2.产 品 展 示

3.其他产品

4.其他英文产品

Asea EB0524B01 driver input power board

| PMB33C-10214-00 | AMAT 0100-90313 | 57160001-HK DSTD 185 |

| PMB33C-10201-03 | AMAT 0100-00496 | KT 5191a |

| PMB33C-10201-02 | 07NG66R1 | UT 372c |

| PMB33C-10201-01 | 07KT31 | 5730030-F DSAI 130 |

| PMB33C-10201-00 | NKTU02 | M21NRXC-LDN-NS-00 |

| PMB33C-10200-03 | IMSDO01 | 57120001-Z DSTA 130 |

| PMB33C-10200-02 | PHBBLK10000100 | R43HEAA-R2-NS-VS-00 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218