GIDINGS&LEWIS 502-03781-00运动控制模块

1.产 品 资 料 介 绍:

产品概述

产品特点

英文资料:

Product Overview

In the current booming development of industrial automation, the GIDINGS&LEWIS 502-03781-00 motion control module has become the backbone of motion control for CNC machine tools, automated production lines, and robot systems due to its outstanding performance. It is like the "smart brain" of industrial equipment, with powerful multi axis synchronous control capability, which can coordinate and command multiple motion axes to ensure precise and error free execution of complex machining paths and automation actions. Through precise position, speed, and torque closed-loop adjustment mechanisms, this module can monitor and correct the operating status of the equipment in real time. Even extremely subtle deviations can be accurately captured and adjusted, ensuring the accuracy and stability of the entire industrial production process and helping enterprises achieve a leap in product quality while efficiently producing.

Product Features

Multi axis synchronous control: In complex machining scenarios of high-end manufacturing, such as precision milling of aerospace components, complex surface machining of automotive molds, and robot execution of precision assembly, welding, etc., the advantages of multi axis synchronous control capability of GIDINGS&LEWIS 502-03781-00 motion control module are fully demonstrated. It supports multi axis linkage and can accurately plan and coordinate the motion trajectories of each axis. When processing complex curve contours on CNC machine tools, this module can simultaneously control multiple coordinate axes such as X, Y, Z, etc., allowing the tool to move accurately along the preset complex curve and produce high-precision parts that meet the requirements. In robot systems, whether it is the collaborative motion of multi joint robotic arms or the navigation and operation of mobile robots in complex environments, it can ensure perfect coordination between various joints or drive axes, achieve complex action sequences, and greatly expand the application scope and processing capabilities of industrial equipment.

High precision control: With the help of advanced closed-loop feedback system, the 502-03781-00 motion control module achieves micrometer level position accuracy and high-precision speed control. In the grinding and processing of precision optical lenses, the flatness and smoothness of the lens surface are highly required. This module collects real-time position and speed information of the motor through closed-loop feedback, compares and analyzes it with preset values, and accurately adjusts the operation of the motor to ensure that the motion accuracy of the grinding tool on the lens surface reaches the micrometer level, thereby processing high-quality optical lenses. In the photolithography process of electronic chip manufacturing, the worktable of the lithography machine needs to move at extremely high speed and precision. This motion control module can accurately control the speed of the worktable, ensure the precise transfer of lithography patterns, meet the strict requirements of chip manufacturing for high precision and high speed, and provide a solid guarantee for precision processing in high-end manufacturing industry.

Quick response: In response to the frequent dynamic load changes and high-speed operation requirements in industrial production, this motion control module has been deeply optimized. It adopts advanced motion algorithms and can quickly respond to load changes during equipment operation, adjusting the output torque and speed of the motor in a timely manner.

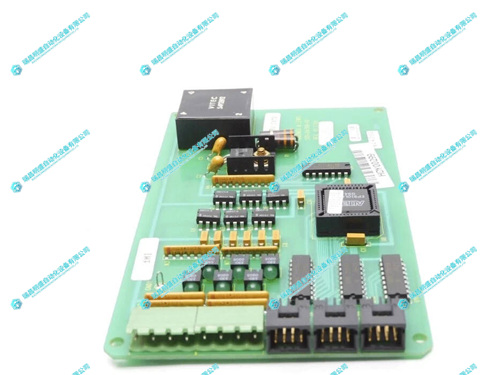

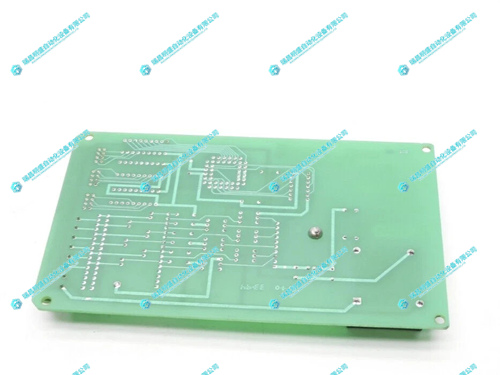

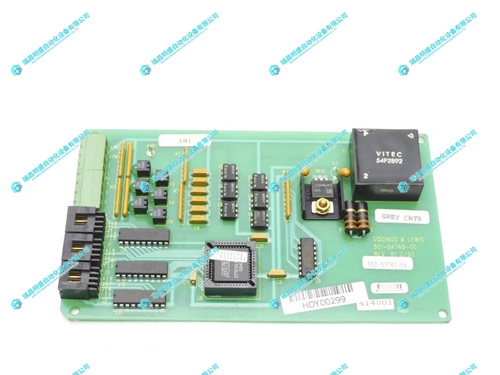

2.产 品 展 示

3.其他产品

4.其他英文产品

UAD155A0111 3BHE029110R0111 Driver

PPD513A0E110110 3BHE039724R0E41 Controll

MAGNETEK MG2-1F-1F power module

| PFRL101A | AMAT 0100-35170 | PFTL 101AER-0.5 |

| PFEL113 | AMAT 0100-90861 | PFTL101A-1.0KN 3BSE004166R1 1.0KN |

| PFEL111 | AMAT 0100-00-01486 | PFTL101A 2.0KNK |

| PFEA113 | AMAT 0100-00192 | PFEA113-20 |

| PFEA112 | AMAT 0100-00133 | PFTL101A 2.0KNK |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218