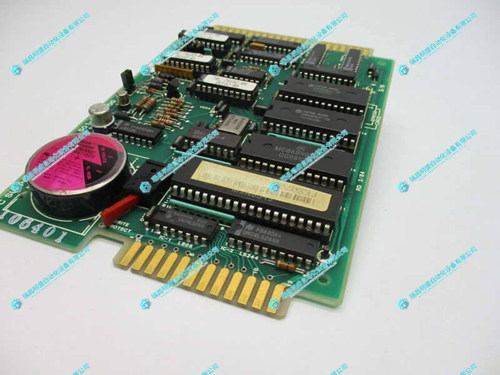

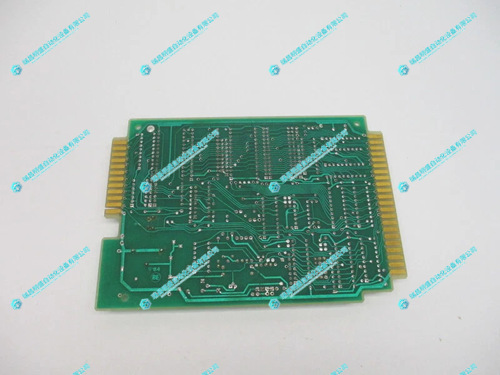

GIDINGS&LEWIS 501-04026-00支持模块板

1.产 品 资 料 介 绍:

产品概述

核心功能特性

英文资料:

Product Overview

GIDDINGS&LEWIS 501-04026-00 support module board is an indispensable and important component of industrial automation control systems. It is like the "behind the scenes hero" of efficient operation of industrial equipment, providing solid support for the stable operation, functional expansion, and signal interaction of the entire system. In complex and diverse industrial environments, from precision CNC machining to large-scale automated production line operations, this support module board plays a key role and is one of the core components to ensure efficient and precise industrial production.

Core functional characteristics

Multi signal processing: With powerful signal processing capabilities, it can simultaneously interface with multiple types of signals. It can accurately collect analog signals from various sensors, such as real-time temperature data from temperature sensors, pressure values feedback from pressure sensors, etc., and efficiently convert these analog signals into digital signals for fast and accurate analysis and processing by the control system. At the same time, for the digital control instructions issued by the control system, the module board can quickly convert them into corresponding analog signals and transmit them to the actuators, such as the operation of the driving motor, the opening and closing of valves, etc., ensuring that industrial equipment operates accurately according to the preset process.

Device collaborative connection: With abundant interface resources, it can easily achieve collaborative connection with various industrial devices. Through digital input and output interfaces, it can be closely connected to digital devices such as switches and relays, monitor the real-time operation status of the equipment, and control the start stop and working mode of the equipment according to control instructions. The analog interface can adapt to various analog sensors and actuators, meeting the high-precision processing requirements of analog signals in industrial production. In addition, it supports serial communication interfaces (such as RS-485, RS-232) and common fieldbus interfaces (such as CANopen, Modbus), which facilitate data communication and collaborative work with other intelligent devices and controllers, greatly improving the integration of the system and the flexibility of device connections.

System stability guarantee: Advanced circuit design and anti-interference technology are adopted to ensure the stable operation of the entire industrial control system. In industrial production sites, there are numerous sources of electromagnetic interference, such as strong magnetic fields generated by large motors and electromagnetic radiation from high-frequency equipment during operation. These interferences can easily affect the normal operation of equipment. 501-04026-00 supports module boards that effectively suppress the impact of external interference signals on the system through good electromagnetic shielding design, efficient filtering circuits, and optimized anti-interference algorithms, ensuring the accuracy and stability of signal transmission, avoiding equipment malfunctions or production accidents caused by signal interference, and ensuring the continuity and reliability of industrial production.

Flexible Function Expansion: With excellent scalability, functional modules can be flexibly added or adjusted according to the needs of different industrial application scenarios. When the production scale of an enterprise expands or the production process is upgraded, specific functional modules can be added to the support module board, such as additional communication modules, to meet the data exchange needs of more devices,

2.产 品 展 示

3.其他产品

4.其他英文产品

HONEYWELL 05704-A-0146 Digital

1TGE120011R1111 Controller Module

PROSOFT MVI46-MCM communicatio

| 8030-PS-35 | 6DD1684-0BB0 | 8030-CRM-510 |

| 8030-PS-31 | 02-00025-00 | 8030-CRM-275 |

| 8030-PS-30 | 193X728AAG01 | 8030-CRM-270 |

| 8030-PS-25 | 6DD1683-0CD0 | 8030-CRM-260 |

| 8030-PS-21 | CACR-IR30SB | 8030-CRM-255 |

| 8030-PS-20 | 6SC6100-0GC08 | 8030-CRM-250 |

| 8030-PS-11 | 6SC6110-0GA01 | 8030-CRM-232 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218