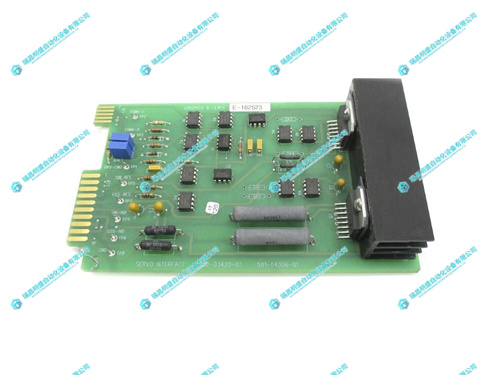

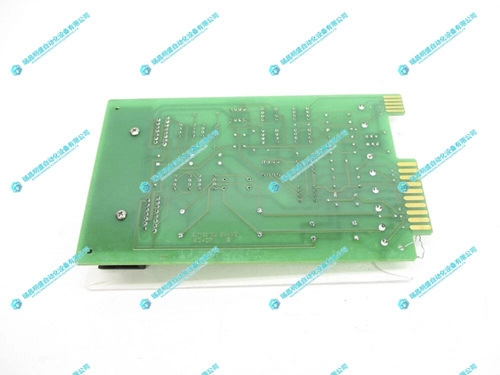

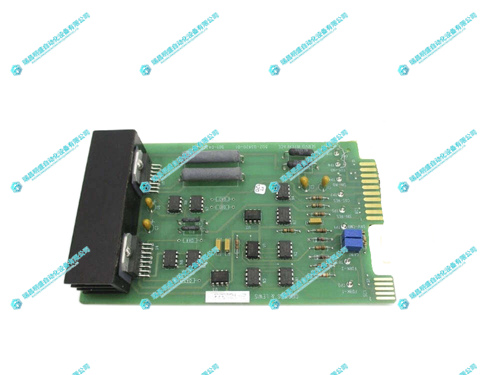

GIDINGS&LEWIS 502-03420-01伺服接口模块

1.产 品 资 料 介 绍:

产品概述

核心功能特性

英文资料:

Product Overview

The GIDINGS&LEWIS 502-03420-01 servo interface module plays a crucial role in the complex system of industrial automation, serving as the core bridge connecting control systems and servo motors. It accurately converts the instructions issued by the control system into driving signals that the servo motor can respond to, thereby achieving precise control of motor motion and ensuring that industrial equipment operates according to preset trajectories and parameters. From precision CNC machining to efficient automated production line operations, and then to flexible industrial robot operations, this module is widely used in many industrial fields that require extremely high precision in motion control. It is a key component to ensure efficient, stable, and accurate industrial production.

Core functional characteristics

Accurate instruction conversion and transmission: With excellent instruction parsing and conversion capabilities, it can quickly and accurately receive various complex motion control instructions issued by upper control systems such as programmable logic controllers (PLCs), industrial computers, etc. Whether it is simple motor start stop, forward and reverse commands, or advanced commands involving complex path planning and multi axis linkage, the 502-03420-01 servo interface module can efficiently convert them into pulse signals, analog voltage or current signals suitable for servo motor operation, to accurately control key parameters such as motor speed, direction, and position. In the machining process of CNC machine tools, according to the instructions of the CNC program, the module can accurately adjust the operation of the servo motor, so that the tool can cut along the preset complex trajectory, ensuring that the machining accuracy of the parts reaches the micrometer level, meeting the strict requirements of high-end manufacturing for precision machining.

Multi signal adaptation and processing: Supports multiple types of signal input and output, with excellent signal adaptation and processing capabilities. In terms of input, it is compatible with digital signals, such as switch signals used to control the basic start stop and working mode switching of motors; At the same time, it also has good reception and processing capabilities for analog signals, such as position, speed, pressure and other analog signals from sensors, which can be used to implement closed-loop control systems, monitor the operating status of motors in real time and make precise adjustments. At the output end, corresponding pulse sequence signals can be output according to control requirements, accurately controlling the rotation angle and speed of the servo motor; For some servo motors that require analog control, the module can output accurate analog voltage or current signals to achieve continuous adjustment of motor operating parameters. By flexibly adapting and processing multiple signals, this module can meet the diverse control needs of servo motors in different industrial scenarios.

Multi axis collaborative control capability: With powerful multi axis collaborative control function, it can simultaneously connect and control multiple servo motors, achieving high-precision synchronous motion of multi axis equipment. In automated production lines, common multi axis robotic arms require multiple servo motors to work together to complete complex tasks such as material handling, processing, and assembly. The 502-03420-01 servo interface module can accurately coordinate the action sequence, speed, acceleration, and position of each axis servo motor according to production process requirements,

2.产 品 展 示

3.其他产品

4.其他英文产品

AMAT 0190-66253 Communication Module

IC3600SVZB1 Computer Adjustmen

| 760-P5-G5-S5-LO-A20-R | 8030-CC-15 | 531X308PCSAEG1 |

| 760-P5-G5-S5-HI-A20-R-T | 8030-CC-10 | F31X133PRUABG1 |

| 760-P5-G5-S5-HI-A10-R | 8030-CBP-320 | F31X134EPRBHG1 |

| 760-P5-G5-D5-HI-A1-R | 8030-ADP-100 | F31X166MHCACG1 |

| 760-P1-G1-S1-LO-A20-R | 8020-SCP-722 | 830-23461-000 |

| 760-P1-G1-S1-LO-A10-R | 8020-SCP-721 | F31X135PRGBBG1 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218