GIDINGS&LEWIS 501-02987-00输入输出模块

1.产 品 资 料 介 绍:

一、产品概述

二、产品特点

英文资料:

In industrial automation control systems, input/output modules are the "bridge" that connects field devices with core control units, and play a key role in signal interaction and instruction execution. The GIDINGS&LEWIS 501-02987-00 input/output module, with its efficient signal processing capabilities and wide adaptability, has become a core component for achieving automation control in various industrial scenarios.

1、 Product Overview

501-02987-00 is a composite module in the Giddings&Lewis system that integrates input and output functions, designed specifically for signal management in industrial sites. It can receive input signals from devices such as switches and sensors, as well as output control instructions to actuators, relays, indicator lights, etc., achieving bidirectional data exchange between on-site devices and CPU or controller modules. Through precise data collection and control output, this module provides real-time basis for the automation decision-making of the system, ensuring that industrial equipment operates efficiently according to preset logic. For example, in a production line, it can transmit the signal of the material arrival sensor to the controller, and at the same time drive the robotic arm to perform grasping actions according to instructions, forming a complete control loop.

2、 Product Features

Multi channel input/output: The module supports multiple digital input and output channels, and can simultaneously connect dozens of field devices to meet the dense signal requirements of complex industrial systems. In a large automated workshop, a production line may involve hundreds of sensors and actuators, and modules manage these signals centrally, avoiding line chaos and improving system integration efficiency. For example, in the automotive welding production line, it can simultaneously receive 20 welding point sensor signals and synchronously output 16 mechanical arm action commands, ensuring precise coordination of the welding process.

Signal isolation design: Electrical isolation technology (such as optocoupler isolation and transformer isolation) is used between input and output circuits, power supply and signal circuits to effectively block the impact of on-site electromagnetic interference and voltage fluctuations on the core control system. In industrial environments where motor groups and frequency converters are concentrated, this design can prevent interference signals from entering the CPU module through signal lines, avoiding false triggering of control instructions. At the same time, isolation protection also reduces the risk of module damage caused by external short circuits or overvoltage, improving system reliability.

High speed response performance: The module adopts optimized signal processing circuits, and the input signal acquisition delay can be controlled in milliseconds. The output command drive speed is fast, ensuring real-time control requirements. In the tool feed control of CNC machine tools, it can quickly receive feedback signals from the position encoder and immediately output adjustment instructions to control the tool positioning error at the micrometer level; In the scenario of assembly line sorting, the full process response of material detection to sorting cylinder action can be completed within 10ms, avoiding missed detection or misclassification.

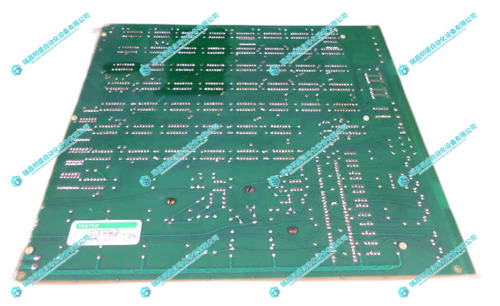

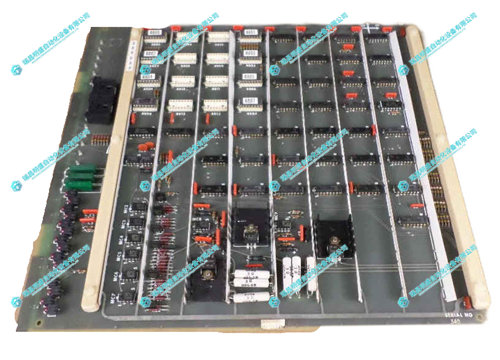

2.产 品 展 示

3.其他产品

4.其他英文产品

AMAT 0190-11415 Digital Input Module

ASEA 2668 184-447 Communication Module

RADISYS EXM-HDEXM-MX Memory Module

| 469-P5-HI-A20-E | HZ171A607 | IC3600STKJ1 |

| 469-P5-HI-A20 | SL1-240R | IC3600STKH1B |

| 469-P5-HI-A1-E | HP56A616 | IC3600STKH1 |

| 469-P1-HI-A20-E-H | HG92A603 | IC3600STKD1 |

| 469-P1-HI-A1-E-H | SSM-28-F | IC3600STKA1 |

| 469-P1-HI-A1-E | HA43B6 | IC3600STFB1A |

| 45VM60-020-4 | HA42A6B211 | IC3600STFA1 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218