GIDINGS&LEWIS 401-30247-00运动控制模块

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS 401-30247-00 模块介绍

一、产品概述

二、产品特点

英文资料:

Introduction to GIDINGS&LEWIS 401-30247-00 module

In the field of precision control in CNC and automation systems, the GIDINGS&LEWIS 401-30247-00 module has become a key force in servo control due to its excellent performance, accurately controlling motor motion and providing solid guarantees for the efficient and precise operation of industrial equipment.

1、 Product Overview

401-30247-00 is an important servo drive or motion control module in the Giddings&Lewis system, mainly responsible for communicating and controlling the core and actuator. It accurately receives instruction signals from the controller or CPU module, which act as a "baton" for the operation of the device. The module converts the received instructions into power to drive servo motors or stepper motors, enabling precise control of motor position, speed, and acceleration. When processing complex components on CNC machine tools, this module precisely adjusts the motor motion according to a preset program, drives the cutting tool to cut the workpiece at a specific speed and precise position, ensuring the machining accuracy reaches the micrometer level and meeting the strict requirements of industrial production for high-precision machining.

2、 Product Features

High precision servo control: supports closed-loop position, speed, and torque control. By collecting real-time motor feedback signals and comparing them with preset values, the output can be dynamically adjusted. For example, on an automated assembly line, when the robotic arm grabs components, the module precisely controls the motor based on position feedback, allowing the robotic arm to accurately grab and place the components, ensuring assembly accuracy and avoiding assembly errors caused by positional deviations.

Quick response capability: capable of quickly processing control signals and possessing excellent dynamic response performance. In high-frequency motion control scenarios, such as high-speed sorting equipment on 3C product production lines, it is necessary to quickly switch the motor operating state. The 401-30247-00 module can quickly respond to control instructions, drive the motor to start and stop quickly, and change speed, achieving efficient material sorting and greatly improving production efficiency.

Modular design: Using standardized interfaces, it is extremely convenient to install on the rack during initial system setup or disassemble and replace during later maintenance. When the automated production line needs to upgrade and expand its functions, adding new motor control requirements, technicians can easily integrate the module into the system to achieve rapid system expansion and reduce system upgrade costs and time costs.

High reliability: Based on industrial design concepts, it has excellent environmental adaptability. In high-temperature metallurgical workshops, internal electronic components are designed with special heat dissipation and selected with high-temperature resistant materials, allowing for stable operation in high-temperature environments; Faced with strong vibrations generated by the operation of machine tools and other equipment, the internal structure is reinforced and the components are welded firmly to ensure stable operation of the module; The anti electromagnetic interference design effectively resists the complex electromagnetic environment of industrial sites, and can work normally around power equipment with severe electromagnetic interference, ensuring the reliability of system operation.

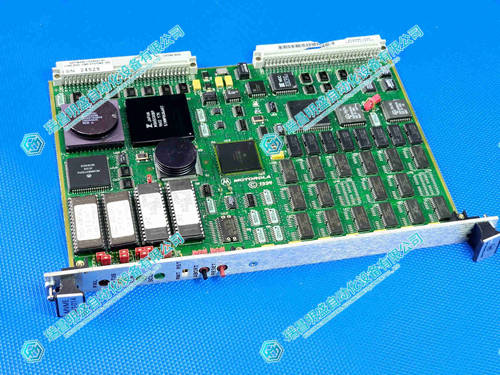

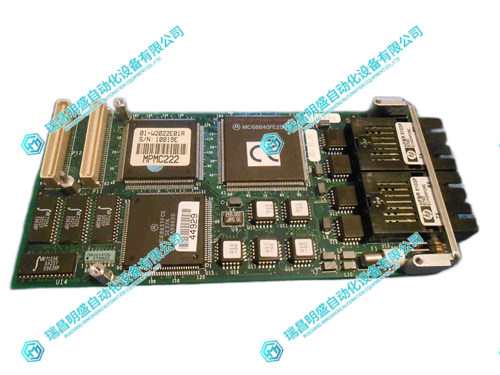

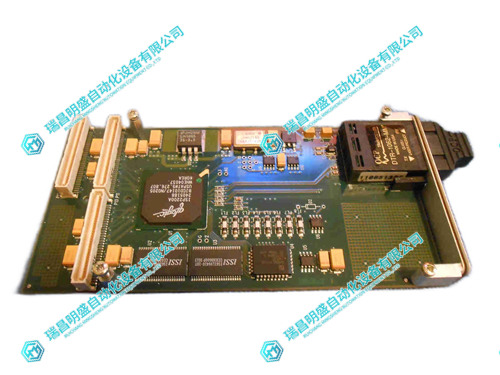

2.产 品 展 示

3.其他产品

ABSOLUTE PROCESS API4380GD隔离变送器

4.其他英文产品

RADISYS 451558-004 Communication Module

ABB UN0942b-P Programmable Controller

Teknic SST-1500-XCX Digital Servo Drive

| 369-HI-0-M-0-0-E | SS2000-PCI | IC3603A177CF6 |

| 369-HI-0-M-0-0 | 531X301DCCAJM1 | IC3603A177AH9 |

| 369-HI-0-B-F-D-0-E | 531X301DCCAHM1 | IC3603A177AH2 |

| 369-HI-0-B-0-0-0-0 | 531X301DCCADM1 | IC3603A177AG9 |

| 369-HI-0-0-0-0 | 531X300CCHBDM3 | IC3603A177AG2 |

| 36-0201 | 531X300CCHAXM3 | IMDSI14 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218