GIDINGS&LEWIS DSM007P定位驱动器

1.产 品 资 料 介 绍:

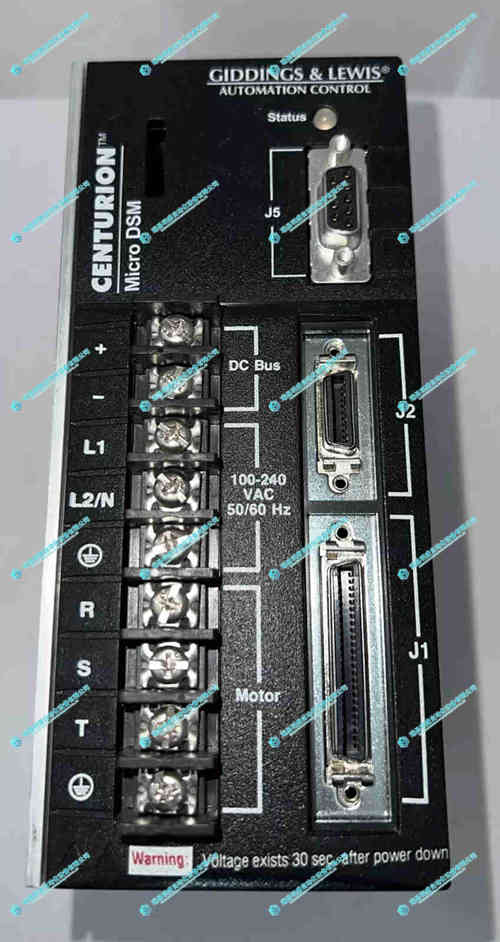

GIDDINGS & LEWIS DSM007P 定位驱动器介绍

一、产品概述

二、产品特点

英文资料:

Introduction to GIDINGS&LEWIS DSM007P Positioning Drivers

In the field of precision motion control in industrial automation, GIDINGS&LEWIS DSM007P positioning drivers play a key role in accurately driving motors, achieving high-precision position control of equipment, and providing core power for efficient and precise operation of various industrial equipment.

1、 Product Overview

DSM007P, as a positioning driver in Giddings&Lewis systems, focuses on driving servo or stepper motors. It is like a "central nervous system" that connects the brain of the control system with the execution mechanism, receiving instruction signals from the controller or CPU module. These signals carry expectations for motor motion, including key parameters such as displacement, velocity, and acceleration. Through advanced closed-loop control technology, DSM007P can monitor the actual operating status of the motor in real time, compare it with the command signal, continuously adjust the output, and accurately control the displacement, speed, and acceleration of the motor, ensuring precise positioning of mechanical motion and meeting the strict requirements of industrial production for high-precision motion.

2、 Product Features

High precision positioning control: supports closed-loop position, velocity, and acceleration control, which means it can obtain the actual position information of the motor in real time through the position feedback interface, combine the monitoring data of velocity and acceleration, and make precise comparisons and dynamic adjustments with preset values. In the context of precision parts machining, the positioning accuracy of the motor can be controlled within a very small range, ensuring that the dimensions of the machined parts are accurate and meet high-precision manufacturing standards.

High speed response capability: With excellent performance in quickly responding to control signals, it can react to instructions issued by the controller or CPU module in a very short time. When high-speed cutting is performed on a CNC machine tool, once the control system issues a command to change the tool feed rate or position, DSM007P can quickly drive the motor to perform the corresponding action, meeting the strict requirements of the equipment for real-time control, avoiding machining errors caused by response delay, and ensuring machining quality and efficiency.

Multi axis control compatibility: It can be flexibly used in conjunction with single axis or multi axis systems, providing solutions for complex motion control. In robot systems, robots typically require multiple joint coordinated movements to complete complex tasks. DSM007P can simultaneously control multiple motor axes, coordinate the motion relationships between each axis, achieve precise linkage of robot joints, and complete high-precision path planning and closed-loop control operations such as welding and handling.

Modular design: Adopting a plug-in structure, this design greatly simplifies the installation, maintenance, and system expansion process. During the system setup phase, technicians can easily insert it into the corresponding slot and quickly complete the installation; When equipment malfunctions during operation and requires maintenance, the faulty module can be easily removed and replaced, greatly reducing downtime. If the system needs to be upgraded and expanded, such as adding new motor control requirements, the driver can also be easily added to enhance the flexibility and scalability of the system.

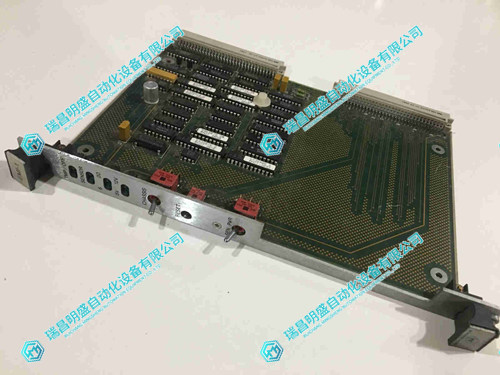

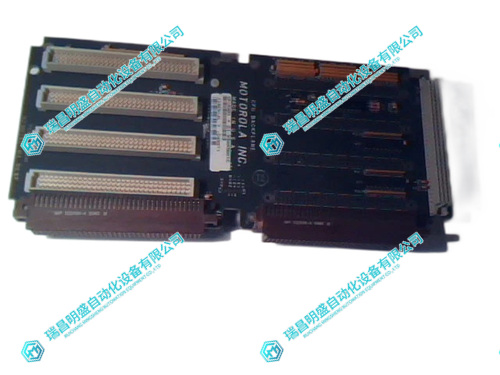

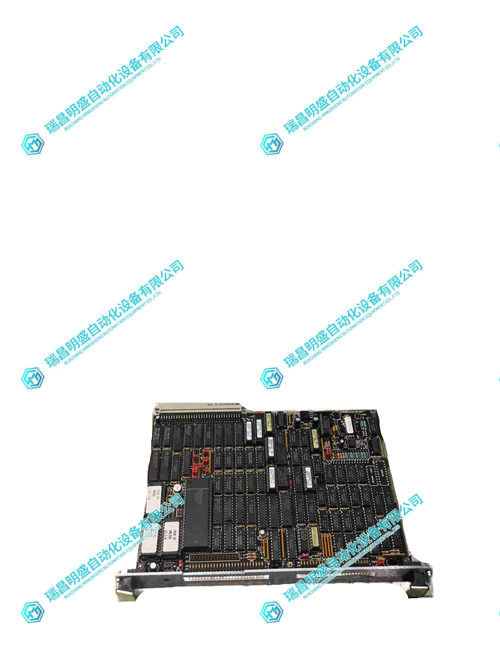

2.产 品 展 示

3.其他产品

KOLLMORGEN CP310250 PRD-P310250Z-55 伺服驱动器

4.其他英文产品

RADISYS 061-01450-0010 Network Adapter

Teknic SST-1500-XCX Digital Servo Drive

| 33VM52-020-9 | 3090-SCCT022 | IC3600VCDA1 |

| 33VM52-008-4 | 3090-RTM-317 | IC3600VBEA1 |

| 33VM52-000-4 | 3090-MCI101 | IC3600VBCU1B |

| 33VM52-000-29 | 3090-CAB108 | IC3600VBCU1 |

| 33VM52-000-20 | 3050-SD200 | IC3600VANB1D |

| 33VM52-000-19 | 3050-SD100 | IC3600VANB1 |

| 33VM52-000-13 | 3050-SD-300 | IC3600VANA1G1E |

| 33VM2-12-T2 | 3050-PIF-85 | IC3600VANA1D1 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218