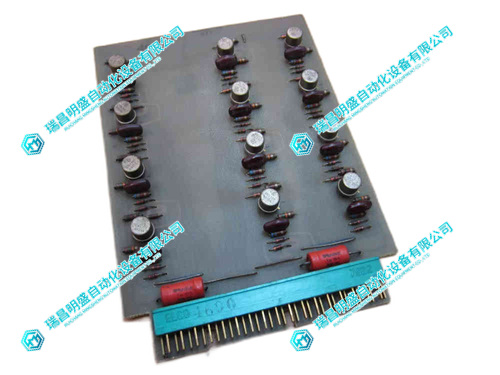

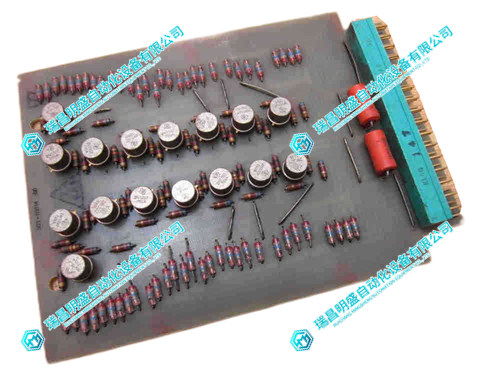

GIDINGS&LEWIS 502-02114-00电路板

1.产 品 资 料 介 绍:

数控机床系统

伺服驱动与运动控制

工业自动化生产线

机器人控制系统

数据采集与反馈系统

英文资料:

Numerical Control Machine Tool System

In CNC equipment such as milling machines, lathes, boring machines, etc., the GIDINGS&LEWIS 502-02114-00 circuit board is in the core control position. It accurately collects various sensor signals, such as machine tool operating status, tool position, etc., and processes them through internal precision logic circuits to convert the processing results into control command outputs. This ensures the precise and error free movement trajectory of the tool, the machining accuracy of the workpiece can reach micrometer level, maintaining stable operation of the equipment and ensuring high precision and efficiency in the processing of complex parts.

Servo drive and motion control

In the servo drive system, this circuit board is the key to achieving high-precision motion control. It efficiently processes signals such as position, velocity, acceleration, etc., generates precise control signals through algorithm calculations, and drives the motor to operate. Whether it is the processing of complex contours or the rapid start stop and precise positioning in automated operations, it can enable the motor to respond accurately, meet the strict requirements of industrial production for high-precision motion, and ensure product processing quality and production efficiency.

Industrial automation production line

Integrated into the automated assembly line control system, the 502-02114-00 circuit board coordinates the operation of equipment in various stages such as transportation, assembly, and testing. It receives product position, type, and other information from the front-end sensors of the production line, processes it, and sends control instructions to subsequent equipment, such as controlling the start and stop of the conveyor belt and adjusting the sequence of assembly robot actions. Its rapid response and precise control have improved production efficiency, giving the production line flexibility to respond to different product production.

Robot control system

When used for industrial robots and robotic arms, this circuit board bears the responsibility of driving and signal processing. It enables the coordinated movement of joints in multi axis robots, adjusts motor output in real-time based on preset path planning instructions, and ensures precise operation of the robotic arm along complex trajectories. At the same time, it collects real-time feedback signals such as joint position and motor current for closed-loop control, ensuring that the robot can maintain stability and accuracy during high-speed motion, and is suitable for various robot operation scenarios such as welding, handling, and sorting.

Data Collection and Feedback System

In the data collection process, it can quickly and accurately collect various sensor signals, such as temperature, pressure, and displacement sensor data. After collection, convert the analog signal into a digital signal, and perform preliminary processing and filtering to remove interference. In a closed-loop control loop, the control strategy is adjusted in a timely manner based on feedback data to ensure real-time and accurate system response. For example, in precision machining equipment, the operating parameters of the equipment are continuously calibrated to maintain machining accuracy.

2.产 品 展 示

3.其他产品

ABB 216EA61b HESG324015R1/K数字量模块

ABB HESG324258R3/I HESG448230R1输出模块

ABB 216NG63 HESG441635R1电源控制模块

4.其他英文产品

3HNM07686-1 Semiconductor module

Mitsubishi A1SJ51T64 main communication module

HE693ADC409A-22 industrial module

| AMAT 0190-35763 | AMAT 0190-09312 | AMAT 0190-21640 |

| AMAT 0100-09287 | AMAT 0190-09315 | AMAT 0190-21701 |

| AMAT 0100-00825 | AMAT 0190-09326 | AMAT 0190-21850 |

| AMAT 0100-20173 | AMAT 0190-09329 | AMAT 0190-22090 |

| AMAT 0100-01957 | AMAT 0190-09330 | AMAT 0190-22130 |

| AMAT 0100-09212 | AMAT 0190-09331 | AMAT 0190-22157 |

| AMAT 010-01779 | AMAT 0190-09332 | AMAT 0190-22161 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218