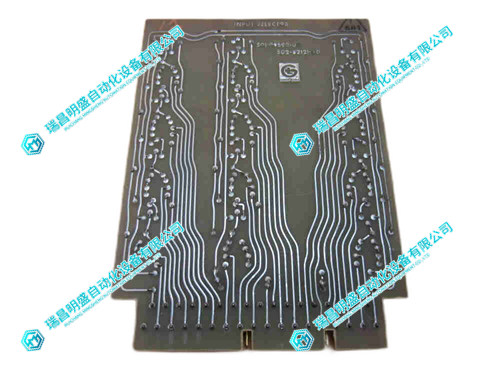

GIDINGS&LEWIS 502-02121-00选择器控制板

1.产 品 资 料 介 绍:

多领域应用的智能选择中枢 ——GIDINGS&LEWIS 502-02121-00 选择器控制板

多元应用领域

英文资料:

Intelligent selection center for multi domain applications - GIDING S&LEWIS 502-02121-00 selector control board

In the complex system of industrial automation, the GIDINGS&LEWIS 502-02121-00 selector control board is like an intelligent commander, accurately controlling the operation mode switching of various equipment and playing an irreplaceable and important role in many key fields.

Diversified application areas

Numerical Control Machine Tool Control System: For CNC machine tools, different machining tasks often require switching between multiple working modes. The 502-02121-00 selector control board bears the responsibility of central coordination here. When switching from conventional milling mode to high-speed and high-precision milling mode, it can quickly send precise instructions to the main control board, servo drive, and I/O module. For example, when processing complex components such as aircraft engine blades, operators can switch to a specific working mode through a selector control board. The board immediately coordinates various modules, making the tool path planning of the machine tool more precise, the servo motor operation more accurate, and the I/O module's control of auxiliary equipment such as coolant and chip removal devices more in line with current processing needs, thereby achieving high-precision machining and ensuring that the complex surface contour of the blades meets design requirements.

Automated production line: In automated assembly or processing production lines, it is necessary to flexibly switch equipment operation modes when producing different models of products or responding to different production processes. Taking the automotive parts automation production line as an example, when switching from producing one type of engine cylinder block to another, the 502-02121-00 selector control board can quickly switch the production process. It receives instructions from the upper computer to switch the operation mode of the assembly robot from grabbing A model parts to grabbing B model parts, while adjusting the speed and rhythm of the conveyor line, as well as the parameters of the testing program, so that the production line can quickly adapt to the production of new products, greatly improving production flexibility, reducing product switching time, and enhancing production efficiency.

Robot control system: Industrial robots often face multi task operation requirements in practical work. The 502-02121-00 selector control board supports the robotic arm to quickly switch between different task modes such as handling, welding, and polishing. In an automotive welding workshop, robots may first perform the task of moving body parts and immediately switch to welding mode after completion. At this point, the selector control board responds quickly, adjusts the control parameters of each joint motor of the robot, changes the working state of the end effector, switches from the gripping fixture to the welding gun, and coordinates the robot's movement path between different workstations, achieving efficient coordination of multiple tasks and workstations, and improving the versatility and work efficiency of robot operations.

2.产 品 展 示

3.其他产品

ABB PFEA111-65 3BSE028140R0065张力控制器

FOXBORO FBM230 P0926GU输入模块

FOXBORO FBM233 P0926GX离散型控制卡

4.其他英文产品

DSMB-01C 3AFE64691929 power supply board

ABB DSMB-02C 3AFE64666606 power supply board

HIMA ELOPII software

| AMAT 0190-05128 | AMAT 0190-34511 | AMAT 0190-25450 |

| AMAT 0190-05271 | AMAT 0190-34533 | AMAT 0190-25588 |

| AMAT 0190-05274 | AMAT 0190-34538 | AMAT 0190-25613 |

| AMAT 0190-05351 | AMAT 0190-34541 | AMAT 0190-25614 |

| AMAT 0190-05382 | AMAT 0190-34763 | AMAT 0190-25724-001 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218