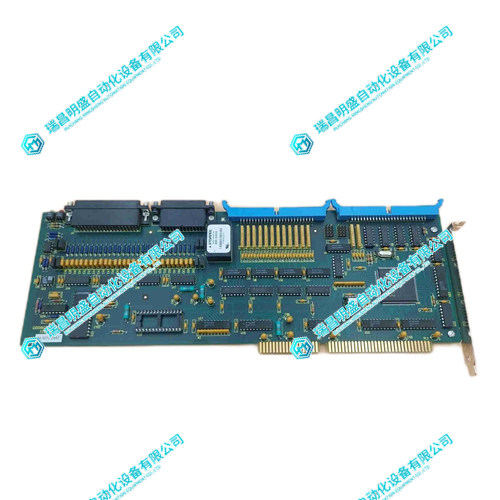

GIDINGS&LEWIS M.1019.2447通信模块

1.产 品 资 料 介 绍:

GIDINGS&LEWIS M.1019.2447 通信模块

一、产品概述

二、技术参数(典型特性,实际数值需参考官方资料)

英文资料:

GIDINGS&LEWIS M.1019.2447 Communication Module

In the increasingly complex and efficient collaboration of industrial automation systems, stable and high-speed data communication between devices has become the key to ensuring the smooth operation of the system. The GIDINGS&LEWIS M.1019.2447 communication module has emerged as the core link in industrial communication networks, responsible for high-speed data exchange between controllers and other modules or external devices.

1、 Product Overview

The GIDINGS&LEWIS M.1019.2447 communication module is specially designed for industrial environments and is a key component that ensures close collaboration between various functional units of industrial automation systems. Its core function is to achieve real-time and accurate transmission of control instructions, status signals, and sensor data. In the vast "symphony orchestra" of industrial control systems, it is like an experienced "conductor", accurately scheduling various types of information, allowing various "instruments" within the system, such as the main control and execution components of CNC machine tools, different workstations of automated production lines, motors and sensors of servo and motion control systems, to "play" in a coordinated manner, avoiding "noise" caused by poor communication, such as production stagnation and control deviation. With excellent performance, this module is widely used in key industrial fields such as CNC machine tools, automated production lines, servo and motion control systems, and has become an important force in promoting industrial production towards intelligence and efficiency.

2、 Technical parameters (typical characteristics, actual values need to refer to official materials)

Clear functional positioning: focusing on high-speed data communication and signal interface functions, fully ensuring the fast and stable transmission of data within industrial systems. Whether it is emergency control instructions issued by the controller, real-time feedback signals of equipment operation status, or massive production data collected by sensors, it can be transmitted and processed with extremely high efficiency, providing solid data support for real-time control and decision-making of the system.

Diverse interface types: equipped with industrial bus interfaces or point-to-point communication interfaces, which can flexibly adapt to different industrial communication architectures. Industrial bus interfaces, such as common Ethernet interfaces, CAN bus interfaces, RS-485 interfaces, etc., can achieve simultaneous connection with multiple devices and build large-scale industrial communication networks; The point-to-point communication interface is suitable for scenarios that require extremely high real-time and confidentiality communication, ensuring exclusive and efficient data exchange between specific devices. This diverse interface design greatly expands its application scope in different industrial environments.

Efficient transmission rate: Supports high-speed data exchange, and the transmission rate can meet the strict requirements of real-time control. In the process of industrial automation production, many links are extremely sensitive to time, such as high-speed cutting of CNC machine tools and rapid material handling of automated production lines. This communication module, with its excellent transmission speed, can instantly complete the sending and receiving of data, ensuring that control instructions are delivered to the executing device in a timely manner, and feedback signals are quickly transmitted back to the controller,

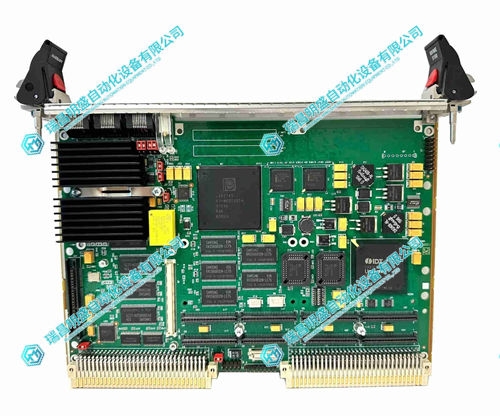

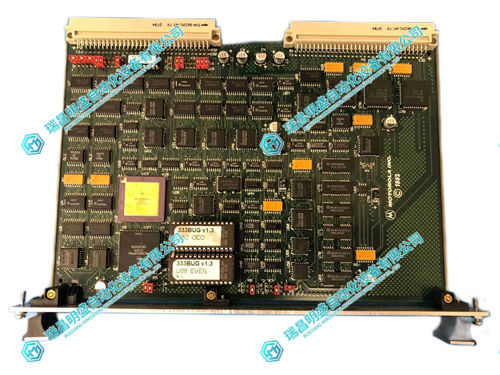

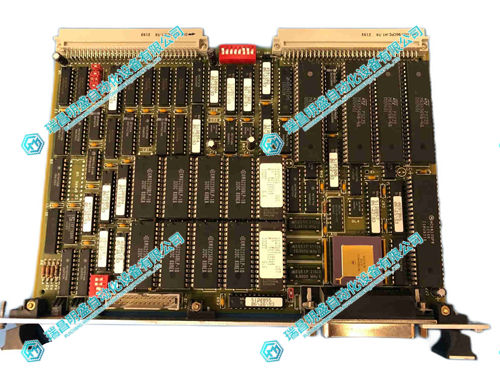

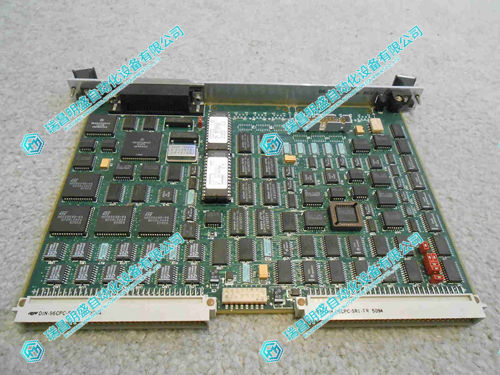

2.产 品 展 示

3.其他产品

FOXBORO P0926PA接线端子

SIM-275D-24 200-582-200-011模块

ICS TRIPLEX T8151B数字输出模块

4.其他英文产品

AUTOMATIONX AXLINK100 892.202988 module

HONEYWELL CC-PAIX01 Sequence control module

HONEYWELL CC-PAOX01 Control module

| PXI-2546 | GESPAC GESSI0-1B | SPFEC12 |

| PXI-2530 | SB511 3BSC970022R2 | DIGTRIC 500 |

| PXI-2503 | DAI02 | PM851K01 3BSE018168R1 |

| PXI-2501 | HONEYWELL 05701-A-0325 | TU830V1 3BSE013234R1 |

| PXI-1045 | DDI01 | 6ES5526-3LG11 |

| PXAH401 | HONEYWELL 05701-A-0326 | DO910 |

| PPU-3 | 6SC9811-4DA04 | 6DD2920-0AR0 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218