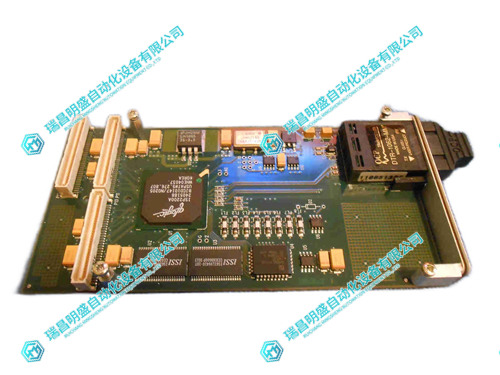

GIDINGS&LEWIS 501-03865-01伺服控制板

1.产 品 资 料 介 绍:

GIDINGS&LEWIS 501-03865-01 伺服控制板

一、产品概述

二、技术特性

英文资料:

GIDINGS&LEWIS 501-03865-01 servo control board

In the current era of accelerating industrial automation, precise and efficient motor control plays a decisive role in improving production efficiency and ensuring product quality. GIDINGS&LEWIS 501-03865-01 servo control board, as a key component in the field of industrial motion control, has become the core support for many industrial equipment to achieve precise motion control with its excellent performance and reliable quality.

1、 Product Overview

GIDINGS&LEWIS 501-03865-01 servo control board is tailor-made for industrial environments, dedicated to providing precise and stable control for servo motors. It is like an "intelligent commander" of industrial equipment, capable of accurately interpreting instructions from the upper controller and converting them into corresponding driving signals, thereby achieving precise control of servo motor speed, position, and torque. Whether it is CNC machine tools performing micro level precision machining, closely coordinated operation of various equipment in automated production lines, or industrial robots performing complex and precise actions, this control board can ensure that mechanical equipment executes complex and high-precision motion tasks with excellent performance. With excellent compatibility, it can work together with various industrial equipment and has become the core unit for achieving efficient and precise motion control in fields such as CNC machine tools, automated production lines, and industrial robots, providing strong support for the intelligent and efficient upgrading of industrial production.

2、 Technical characteristics

Multi control mode collaboration: supports closed-loop servo control, covering three control modes: position, speed, and torque. In position control mode, it is like having a "micro perspective", which can accurately set the operating position of the servo motor with minimal deviation, ensuring accurate equipment positioning. For example, when machining complex parts on CNC machines, the tool position can be precisely controlled to allow the tool to cut along a fine trajectory, ensuring machining accuracy. The speed control mode is like a precise "rhythm master", ensuring that the motor runs at a stable and accurate speed, meeting the needs of scenarios such as uniform material conveying by conveyor belts in automated production lines, and ensuring an orderly production rhythm. The torque control mode is like a 'force controller', providing guarantees for tasks that require precise torque output. For example, industrial robots can accurately control torque when grabbing fragile items, avoiding damage to the items and ensuring the safety and accuracy of operations.

Rich interfaces and efficient interconnection: equipped with multiple digital input and output interfaces, it can easily receive encoder feedback signals, realizing real-time monitoring and adjustment of motor operation status. The digital input interface is like a sensitive "tentacle" that can quickly respond to external control signals, such as device start/stop commands, limit switch signals, etc., and transmit these signals to the control board for processing in a timely manner. The digital output interface is like a powerful "arm" used to control the actions of actuators, such as controlling the forward and reverse rotation of motors, braking, etc., accurately executing the instructions issued by the control board.

2.产 品 展 示

3.其他产品

EMERSON 1C31166G01模拟输入模块

Motorola MVME6100嵌入式处理器模块

YOKOGAWA CP451-51控制器CPU

4.其他英文产品

PFSK142 3BSE006505R1 Control system card

PM891 3BSE053240R1 conversion module

PU519 3BSE018681R1 controller board

| PMB33F-00216-01 | 70AA02B-E | P21NRXA-LNF-NS-00 |

| PMB33F-00216-00 | 70FV01B-E | P22NRXA-LSF-NS-02 |

| PMB33F-00214-03 | 70BK02B-E | M21NRXB-LDN-NS-00 |

| PMB33F-00214-02 | 70 WB 01a | P21NRXD-LNN-NS-00 |

| PMB33F-00214-01 | DT 371a | P22NSXD-LNN-NS-02 |

| PMB33F-00214-00 | 70PR 03d-E | P22NRXD-LNF-NS-00 |

| PMB33F-00201-03 | 70PR05B-ES | N31HCHJ-LNK-NS-01 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218