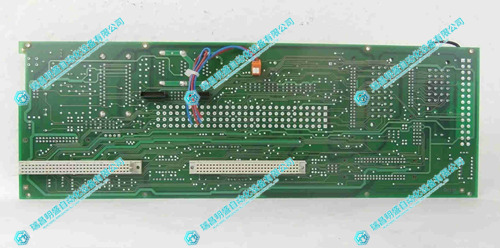

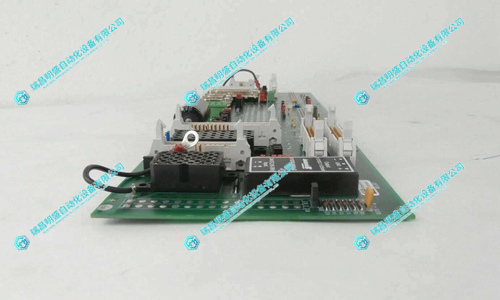

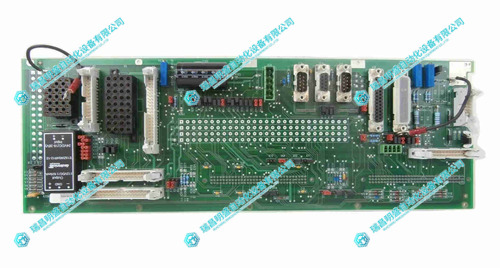

Huttinger 935416-16背板接口PCB

1.产 品 资 料 介 绍:

英文资料:

Introduction to Hutonger 935416-16 Backplane Interface PCB

The Huttinger 935416-16 backplane interface PCB is a printed circuit board that plays a critical role in the connection architecture of industrial electronic devices. As a hub for internal signal transmission and device connection in the system, this backplane interface PCB is designed to meet the requirements of stable and high-speed data and signal transmission in complex industrial environments, ensuring seamless communication and collaborative work between components. It is widely used in various industrial control systems, RF equipment integration, and scientific research experimental devices with extremely high reliability requirements for data transmission.

From the perspective of functional characteristics, its core function is to achieve efficient connection and signal interaction between different circuit boards and devices. It is like the "information highway" in industrial equipment, which can integrate and transmit signals from different components such as the control board, RF control module, power module, etc., ensuring smooth and unobstructed communication of information between various parts of the system. In a complete industrial RF system, the backplane interface PCB can quickly and stably transmit precise control signals generated by the RF control module to the RF generator, while also transmitting feedback signals of the generator's operating status back to the monitoring and control system, ensuring precise control and real-time monitoring of the entire RF process.

In terms of technical parameters, the 935416-16 backplane interface PCB exhibits excellent performance. It adopts a high-density circuit layout design, which can accommodate a large number of signal transmission lines, just like the dense transportation network in the city, efficiently carrying parallel transmission of numerous signals. Referring to similar high-performance backplane interface PCB products, it may have high-speed data transmission capabilities of up to [X] Gbps, meeting demanding application scenarios such as high-definition video signal transmission and real-time processing of large data volumes. In terms of electrical performance, it has extremely low signal transmission delay, ensuring fast signal transmission between different components, reducing system response time, and improving overall operational efficiency. For example, signal transmission delay may be as low as [X] ns, which can ensure the accuracy and timeliness of experimental data acquisition and processing in scientific research experimental equipment that requires extremely high time accuracy.

In terms of connection, the backplane interface PCB is equipped with multiple types of interfaces to meet different connection requirements. Its interface design may have referred to industry standards, such as using connectors similar to DIN 41612 standard, which have good mechanical stability and electrical connection reliability. It may have multiple rows of pins or contacts, such as the common 3-row 96 contact design, providing sufficient connection points for signal transmission of different functions, ensuring accurate and error free connection and transmission of various signals. In terms of connection methods, reliable connection processes such as soldering, such as wave soldering technology, are used to ensure that the interface maintains stable electrical connections even in the face of factors such as vibration and temperature changes in industrial environments during long-term use, avoiding signal interruptions or transmission errors caused by loose connections.

2.产 品 展 示

3.其他产品

EMERSON 1C31234G01DeltaV系列数字输出模块

BENTLY 330104-00-05-10-02-CN 加速度传感器

ABB 3BDH000364R0002 PM783FB0数字输入/输出模块

4.其他英文产品

EATON DPM-MC2 Main communication module

GE IC660ELB912J Gas turbine module

IC660ELB921M Gas turbine electrical card

| PMB31D-20116-02 | Amat 0100-20213 | P22NRXA-LDS-M1-02 |

| PMB31D-20116-01 | 07KT92 | 57160001-ADS DSTD 186 |

| PMB31D-20116-00 | IMASO11 | 5730032-BC DSAX 110 |

| PMB31D-20114-03 | NIAC01 | 5730032-H DSTK 151V |

| PMB31D-20114-02 | IMCIS12 | N32HMFL-LNK-NS-00 |

| PMB31D-20114-01 | 07BT60R1 | PMB33F-20101-02 |

| PMB31D-20114-00 | AMAT 0100-90650 | ZT 372a-E |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218