GIDINGS&LEWIS 810-22752-00伺服驱动器

1.产 品 资 料 介 绍:

GIDINGS&LEWIS 810-22752-00 伺服驱动器

产品概述

技术特点

高精度驱动控制

多模式控制适配

实时反馈与调整

英文资料:

GIDINGS&LEWIS 810-22752-00 servo drive

Product Overview

In the precision control system of industrial automation, GIDINGS&LEWIS 810-22752-00 servo drive is the core link connecting CNC system and servo motor. Its main responsibility is to accurately interpret and efficiently convert the control instructions issued by the CNC system, and then drive the servo motor to achieve precise and stable operation according to preset requirements. It is a key component to ensure that industrial equipment completes high-precision and high-speed motion control tasks.

This servo drive is usually integrated into the electronic control system of industrial equipment. Whether it is cutting processing of large CNC machine tools or precision assembly of automated production lines, it can accurately transmit control instructions to servo motors with excellent performance, providing stable and reliable power support for the motors, ensuring the coordinated operation of various components of the equipment, and successfully completing complex industrial production tasks.

Technical Features

High precision drive control

The GIDINGS&LEWIS 810-22752-00 servo drive has an advanced and precise drive control algorithm system, which can accurately adjust the speed, position, and torque of the servo motor. In the milling operation of ultra precision parts in CNC machining centers, the precision of tool path positioning is extremely high. This driver can control the motor position accuracy within a very small error range according to CNC instructions, ensuring that the tool cuts accurately along the preset path, reducing machining errors, and improving product quality. At the same time, during the entire process of motor start-up, acceleration, constant speed operation, and deceleration stop, the speed and torque curves can be precisely controlled to ensure smooth and stable operation of the motor, avoiding speed fluctuations and impacts, and providing stable power support for high-precision machining.

Multi mode control adaptation

Support multiple flexible control modes to meet the needs of different industrial application scenarios. Can operate in position control mode, accurately control the movement position of the robotic arm in the material handling process of automated production lines, and achieve accurate material grasping and placement; It can also be switched to speed control mode to ensure that the spinning motor runs at a stable speed during the high-speed spinning process of textile machinery, ensuring consistent spinning quality; The torque control mode can also be used to accurately adjust the motor torque in the packaging machinery sealing process, ensuring the sealing firmness and aesthetics. This multi-mode control adaptation capability greatly expands its application scope, enabling it to play a key role in different industries and types of industrial equipment.

Real time feedback and adjustment

By adopting a closed-loop control strategy and closely cooperating with feedback devices such as motor encoders and rotary transformers, a stable "dynamic adjustment closed-loop" is constructed. When the actual operating state of the motor deviates from the preset value due to load changes, mechanical wear, etc., the feedback device monitors the changes in real time and quickly transmits the signal to the GIDINGS&LEWIS 810-22752-00 servo drive. After receiving the signal, the driver immediately performs high-speed and precise analysis and calculation, quickly adjusts the drive signal output to the servo motor, corrects the deviation of the motor in a timely manner, returns to the preset running trajectory, effectively ensures the stability and reliability of the servo system, and greatly improves the operating accuracy of industrial equipment under complex working conditions

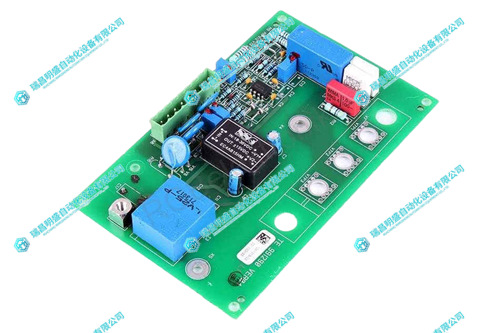

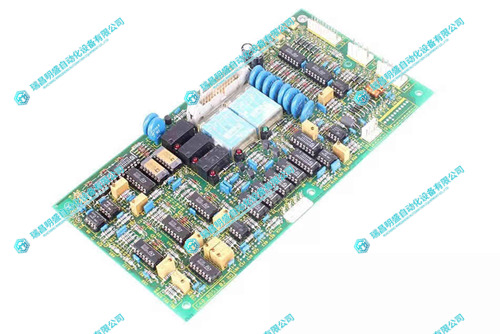

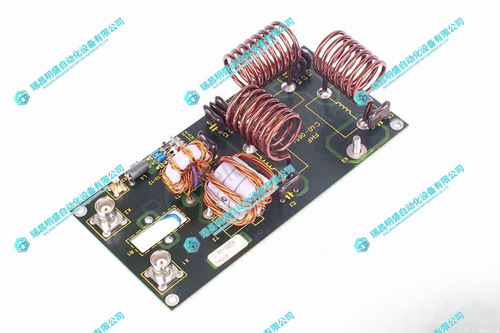

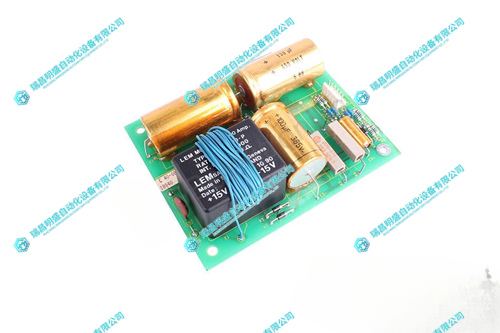

2.产 品 展 示

3.其他产品

WOODWARD 9907-572负载共享模块

YOKOGAWA AQ6375光学多功能仪

PM891K02 3BSE053240R1总线通信模块

4.其他英文产品

BENTLY 125760-01 vibration monitor

BENLTY 125840-01 Monitor card

BENTLY 3500/15 Power supply module

| IS220PAOCHIA IS220PAOCH1B | S5001 | BUS MONITOR |

| IS220PAICH2A IS220PAICH2B | 52010-00 | IMDSI02 |

| IS220PAICH1A IS220PAICH1B | SS2000PCI-2 | IMSET01 |

| IS215UCVGH1A | HA42A6-R233 | IMDS001 |

| IS215UCVFH2AB | SE06200-000000 | IMASI03 |

| IS215ACLEH1C | S60300-NA | IMASOO1 |

| IS215ACLEH1B | SLO-SYN430P1 | INICT01 |

| IS215ACLEH1A | H3801 | 47545701 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218