GIDINGS&LEWIS 502-02192-00控制板

1.产 品 资 料 介 绍:

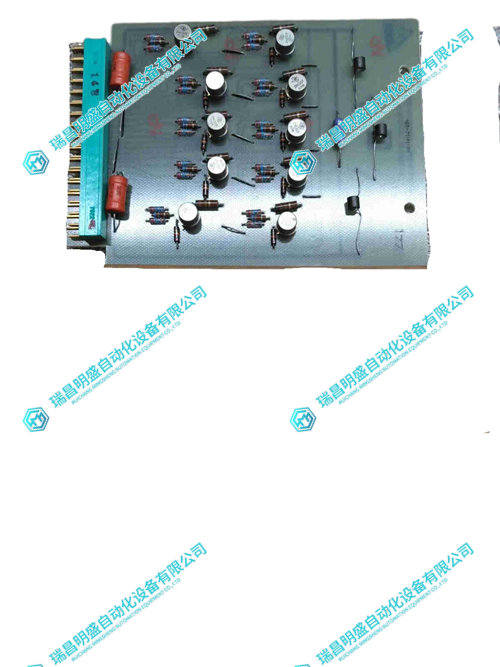

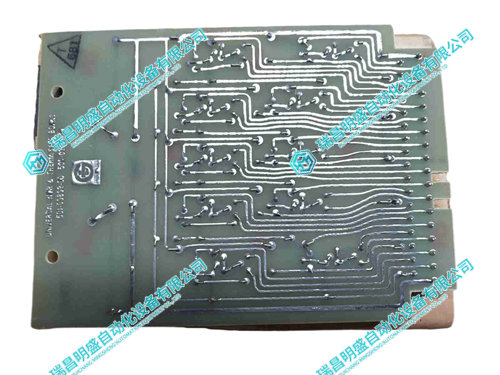

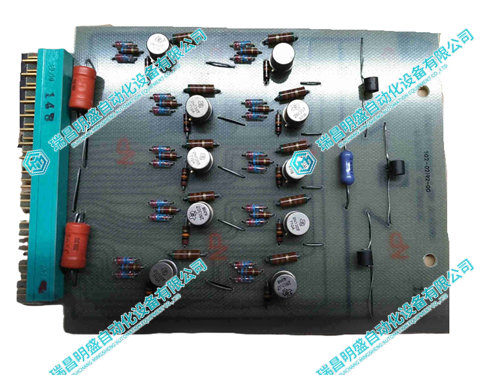

GIDINGS&LEWIS 502-02192-00 控制板

产品概述

技术特点

多轴协调控制

实时响应

模块化设计

英文资料:

GIDINGS&LEWIS 502-02192-00 Control Board

Product Overview

In the precision control system of CNC machine tools and automation systems, the GIDINGS&LEWIS 502-02192-00 control board is the core control module, like the "nerve center" of the entire system. Its main function is to receive instructions from upper control units (such as CPU boards or servo control boards), and through precise internal signal processing and conversion, convert these instructions into specific control signals for actuators, servo drives, or peripheral devices. As an important module for achieving precise motion control and multi axis linkage of machine tools, it provides a solid control foundation for the efficient completion of complex machining tasks, ensuring that the equipment can operate with high precision and high coordination in various industrial scenarios.

Technical Features

Multi axis coordinated control

The GIDINGS&LEWIS 502-02192-00 control board has powerful multi axis coordinated control capabilities and can support synchronous control of multi axis servo or stepper motors. Through precise internal algorithm scheduling, the motion parameters of multiple axes (such as position, velocity, acceleration) can be uniformly planned and adjusted in real time, ensuring the high coordination of each axis action and achieving complex machining actions. For example, when machining complex curved parts such as propellers on a five axis linkage machining center, the control board can coordinate the movements of the X, Y, and Z linear axes and two rotational axes simultaneously, ensuring that the cutting tool always maintains the optimal cutting posture and guaranteeing the machining accuracy and surface quality of the parts.

Responsive

Using high-performance processing chips and optimized circuit design, this control board has the ability to process control signals at high speed and achieve real-time response. After the upper control unit issues instructions, the control board can complete instruction parsing, parameter calculation, and signal output in a very short time, ensuring accurate and timely machine tool actions. In high-speed milling, this real-time response characteristic is particularly critical, as it can quickly adjust the feed rate and spindle speed according to changes in cutting conditions, avoiding machining errors caused by signal delays and improving production efficiency.

modular design

Continuing the advantages of modular design in industrial equipment, the GIDINGS&LEWIS 502-02192-00 control board can be directly installed in racks or control cabinets, with a simple and convenient installation process. This design greatly facilitates later maintenance and replacement. When the control board malfunctions, technicians do not need to disassemble the entire control system on a large scale. They only need to quickly plug and replace modules to restore equipment operation, greatly reducing downtime and improving system usability. Meanwhile, the modular structure also provides convenience for system function expansion, allowing for flexible increase in the number of control axes or expansion interfaces according to production needs.

2.产 品 展 示

3.其他产品

AMAT 0010-02342加热器

PGC5000C色谱分析仪

R&S ZNB8矢量网络分析仪

4.其他英文产品

YOKOGAWA ATK4A-00 terminal

CP238TA Expansion CARDS

CP238TA1 Expansion CARDS

| IC3600LSRD1 | 531X185CPTAKG1 | IC3600EPSD1C1B |

| IC3600LSRB1A | 531X184IPTAFG1 | IC3600EPSC1B |

| IC3600LSRB1 | 531X184IPTAEG1 | IC3600EPSC1 |

| IC3600LSRA1 | 531X184IPTADG1 | IC3600EPSB1C |

| IC3600LSOC1B | 531X182IFGAJG1 | IC3600EPSB1B |

| IC3600LSOC1 | 531X182IFGAHG1 | IC3600EPSB1A |

| IC3600LSFD1B1B | 531X182IFGAEG1 | IC3600EPSB1 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218