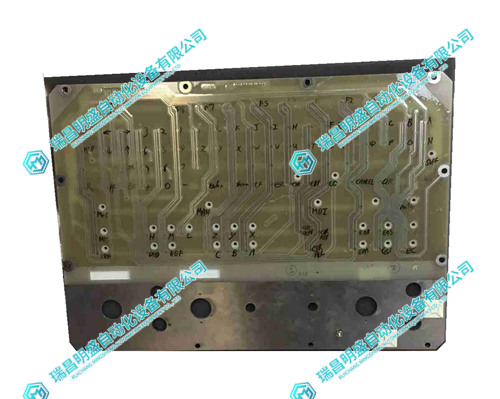

GIDINGS&LEWIS 800-01342-18数控键盘面

1.产 品 资 料 介 绍:

GIDINGS&LEWIS 800-01342-18 数控键盘面

产品概述

按键布局与功能详解

英文字母键

数字键

英文资料:

GIDINGS&LEWIS 800-01342-18 CNC keyboard face

Product Overview

In the human-machine interaction of the CNC system, the GIDINGS&LEWIS 800-01342-18 CNC keyboard plays an extremely important role as a key operating component, equivalent to the MDI (Manual Data Input) panel in the CNC system, which is commonly referred to as the CNC panel. This keyboard panel integrates a rich variety of key types, including English letter keys, function keys, and numeric keys. These keys are arranged in an orderly manner and work together to build an efficient communication bridge between operators and CNC equipment, fully meeting the core operational needs of programming and modifying various parameters in the CNC machining process.

Detailed explanation of button layout and functions

English letter keys

The English letter keys play a fundamental role in CNC programming and instruction input. When writing machining programs, operators need to input various command codes through these letter keys, such as G code (used to specify the machine tool motion mode, such as G00 for quick positioning, G01 for linear interpolation, etc.), M code (controlling machine tool auxiliary functions, such as M03 for spindle forward rotation and M05 for spindle stop). Each letter carries a specific programming meaning, which is combined with each other to construct a complex and precise numerical control instruction system, providing detailed operational guidance for the automated machining of machine tools. For example, when developing a program for milling the contour of a part, an instruction format such as "G01 X_YZ_f_" may be used, where the letters X, Y, and Z are used to specify the tool's motion coordinates in three-dimensional space, and F is used to specify the feed rate, all of which need to be accurately entered through the English letter keys on the CNC keyboard surface.

numeric key

The number keys and English letter keys work closely together and are indispensable in the data input process. Whether it is setting the coordinate values of the machine coordinate system or specifying machining parameters such as cutting speed, feed rate, tool radius compensation value, etc., precise input of specific numbers is required. When setting the origin of the machine coordinate system, the operator needs to input the corresponding X, Y, and Z axis coordinate values through the number keys to ensure accurate correspondence between the machine coordinate system and the part machining coordinate system; When adjusting machining parameters, such as increasing the cutting speed from 100 meters per minute to 120 meters per minute, it is necessary to modify the speed value in the program through the number keys to meet the requirements of different machining processes for parameters and ensure machining quality and efficiency.

2.产 品 展 示

3.其他产品

IS420UCSBH3A 控制器模块

LAM 853-227247-001机器人套装

IS415UCVHH1A 印刷电路板

4.其他英文产品

IC660ELB921M Gas turbine electrical card

KUC711AE101 3BHB004661R0101 Excitation controller

ALSTOM LE109A-1 Communication circuit board

| IC3600LLEA1 | 531X170TBSAAG1 | IC3600ARMB1C |

| IC3600LLDD1A | 531X167MFRALG1 | IC3600ARHB1C |

| IC3600LLDB1 | 531X166MHCAFG1 | IC3600APAB1A |

| IC3600LIVF1 | 531X161PRTABG1 | IC3600APAB1 |

| IC3600LIVE1 | 531X159MPEARG1 | IC3600AOAL1D1C |

| IC3600LIVD1A | 531X159MPEAMG1 | IC3600AOAL1D1B |

| IC3600LIVD1 | 531X158FFDADG1 | IC3600AOAL1D1 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218