1.产 品 资 料 介 绍:

192S04M0131A分布式控制系统(DCS)应用领域

192S04M0131A分布式控制系统(DCS)具备集中监视管理、分散控制执行能力,支持冗余通信与多协议兼容,可实现工艺参数精准调控、报警预警及数据追溯,适配各行业流程化生产与运维需求,具体应用如下:

1. 石油化工生产:管控催化裂化、精馏装置,实现温度压力串级控制,集成安全联锁功能。

2. 火力发电厂:协调锅炉、汽轮机系统,优化燃烧效率,保障机组稳定运行与负荷调节。

3. 冶金冶炼工程:控制高炉炼铁、炼钢工艺,精准调控物料配比与炉内温压参数。

4. 新能源光伏电站:集群管控逆变器,响应电网调度,实现功率动态调节与数据采集。

5. 污水处理厂:自适应控制曝气池溶解氧浓度,动态调整加药量,提升污水处理效率。

6. 制浆造纸工业:管控制浆、抄纸全流程,稳定浆料浓度、纸张厚度等关键工艺参数。

7. 水泥生产企业:覆盖原料研磨、煅烧工序,优化窑炉运行,降低能耗与污染物排放。

8. 城市热电联产:协调冷热电三联供系统,实现能源高效分配与供需平衡调控。

9. 煤化工项目:管控合成氨、甲醇生产工艺,保障高压、高温工况下的安全稳定运行。

10. 食品发酵行业:精准控制发酵罐温湿度、pH值,实现批次化生产的工艺一致性。

11. 制药生产车间:符合GMP规范,管控无菌生产流程,生成电子批记录便于追溯。

12. 水力发电站:控制水轮机、发电机组,实现水位调节与发电功率精准管控。

13. 煤炭开采加工:管控矿井通风、提升系统,监测瓦斯浓度,保障生产安全。

14. 智能水务管网:均衡供水管网压力,监测流量泄漏,降低爆管风险与水资源损耗。

15. 船舶动力系统:管控船舶主机、辅机运行,实时监测工况参数,保障航行安全稳定。

注:产品核心优势为高可靠性、冗余容错与灵活扩展性,支持多协议集成,适配复杂工业工况与规模化管控需求。

192S04M0131A分布式控制系统 英文资料:

192S04M0131A Distributed Control System (DCS) Application Fields

The 192S04M0131A distributed control system (DCS) has centralized monitoring and management, decentralized control execution capabilities, supports redundant communication and multi protocol compatibility, can achieve precise control of process parameters, alarm and warning, and data traceability, and is suitable for the process oriented production and operation and maintenance needs of various industries. The specific applications are as follows:

1. Petrochemical production: Control catalytic cracking and distillation units, achieve temperature and pressure cascade control, and integrate safety interlock functions.

2. Thermal power plants: Coordinate boiler and turbine systems, optimize combustion efficiency, ensure stable operation of units and load regulation.

3. Metallurgical smelting engineering: Control the ironmaking and steelmaking processes of blast furnaces, accurately regulate material ratios and furnace temperature and pressure parameters.

4. New energy photovoltaic power station: Cluster controlled inverters, responding to grid scheduling, achieving dynamic power regulation and data collection.

5. Sewage treatment plant: Adaptive control of dissolved oxygen concentration in the aeration tank, dynamic adjustment of dosage, and improvement of sewage treatment efficiency.

6. Pulp and paper industry: Control the entire process of pulp and paper making, stabilize key process parameters such as pulp concentration and paper thickness.

7. Cement production enterprises: covering raw material grinding and calcination processes, optimizing kiln operation, reducing energy consumption and pollutant emissions.

8. Urban cogeneration: Coordinate the cooling, heating, and power system to achieve efficient energy distribution and supply-demand balance regulation.

9. Coal chemical project: Control the production process of synthetic ammonia and methanol to ensure safe and stable operation under high pressure and high temperature conditions.

10. Food fermentation industry: Accurately control the temperature, humidity, and pH value of fermentation tanks to achieve process consistency in batch production.

11. Pharmaceutical production workshop: Complies with GMP standards, controls sterile production processes, and generates electronic batch records for easy traceability.

12. Hydroelectric power station: Control the water turbine and generator set to achieve precise control of water level regulation and power generation.

13. Coal mining and processing: Control mine ventilation and lifting systems, monitor gas concentration, and ensure production safety.

14. Intelligent water supply network: Balance the pressure of the water supply network, monitor flow leaks, reduce the risk of pipe bursting and water resource loss.

15. Ship Power System: Control the operation of the ship's main and auxiliary engines, monitor real-time operating parameters, and ensure safe and stable navigation.

Note: The core advantages of the product are high reliability, redundant fault tolerance, and flexible scalability, supporting multi protocol integration, and adapting to complex industrial working conditions and large-scale control requirements.

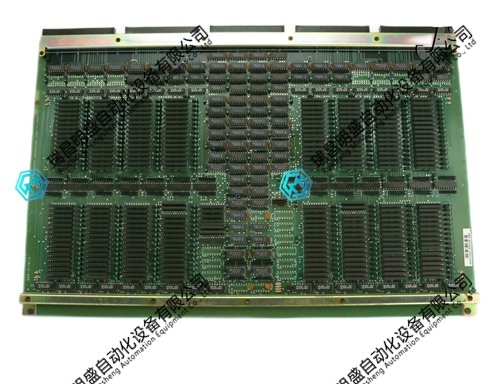

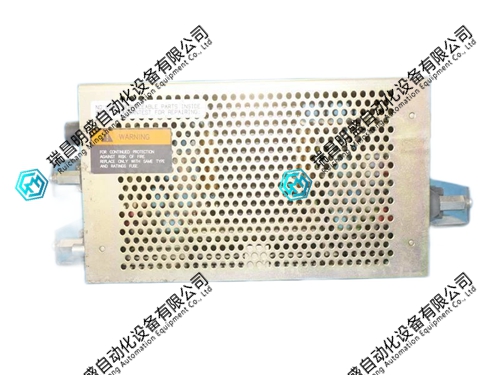

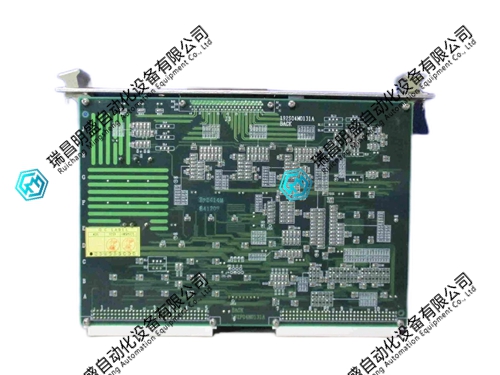

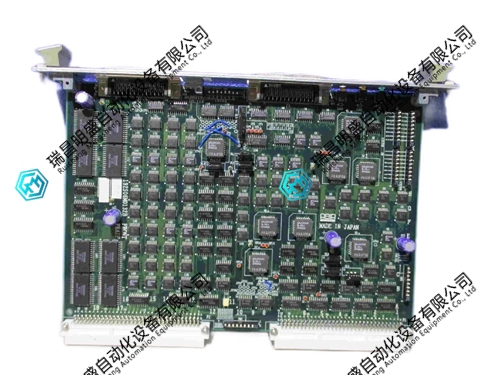

192S04M0131A分布式控制系统 产品展示

产品视频

3.其他产品

ICS TRIPLEX T8160工业控制系统模块

TRICONEX 3604E控制器

ICS TRIPLEX T8193模块化控制系统

4.其他英文产品

RELIANCE 57C328 Remote I/O Network Interface Module

KOLLMORGEN S70601-SE Digital Output Module

HONEYWELL CC-TUIO31 I/O Module

| 5220 | 03-169460-00 | IMRI002 |

| 5215 | 193X801BAG01 | INICTO3A |

| 5210 | 8055-SCP-452 | IMDSO02 |

| 50-0176-C | 3090-VPM-277-C1 | 720-21421-001 |

| 4VM82-008-4 | 3090-TB6 | UFC921A101 |

| 4VM82-000-8 | 3090-SRK-2 | IC3600SVSA1 |

| 4VM81-220-5 | 3090-SPM2000 | IC3600SVFA1B |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218