KLA Tencor 710-611867-000图像板

1.产 品 资 料 介 绍:

中文资料:

KLA Tencor 710-611867-000 图像板(Imaging Board) 是KLA Tencor高端半导体检测设备中的关键图像采集与处理模块,负责从光学传感器或相机接收图像信号,并进行初步处理和数据传输,为后续的缺陷检测和分析提供高质量的图像数据支持。

一、产品基本信息

型号:710-611867-000

类型:图像采集与处理板(Imaging Board)

所属系列:KLA Tencor 710系列

主要功能:高性能图像信号采集、初级图像处理与数据接口管理

二、主要功能与特点

| 功能 | 描述 |

|---|---|

| 图像信号采集 | 连接CCD、CMOS等光学传感器,实时捕获高分辨率图像信号 |

| 图像预处理 | 包括噪声滤波、增益调整、图像增强等,提升图像质量 |

| 高速数据传输 | 通过高速总线(如PCIe、专用高速接口)向主处理单元传输图像数据 |

| 同步控制 | 与扫描平台、激光源等设备同步,确保图像采集时序精准 |

| 多通道支持 | 支持多路图像信号输入,实现多传感器协同采集 |

| 稳定可靠 | 工业级设计,适应复杂半导体制造环境中的高频率工作需求 |

三、应用领域

晶圆表面缺陷检测

采集高分辨率表面图像,用于缺陷识别、定位与分类。自动光学检测(AOI)系统

实现快速、高质量的图像采集,支持高速在线检测。光学量测设备

提供成像数据基础,辅助形貌分析、厚度测量等功能。电子束(e-beam)成像系统

在电子束检测设备中,用于采集次级电子图像或其他信号。

英文资料:

The KLA Tencor 710-611867-000 Imaging Board is a key image acquisition and processing module in KLA Tencor's high-end semiconductor testing equipment. It is responsible for receiving image signals from optical sensors or cameras, performing preliminary processing and data transmission, and providing high-quality image data support for subsequent defect detection and analysis.

1、 Basic Product Information

Model: 710-611867-000

Type: Imaging Board

Series: KLA Tencor 710 Series

Main functions: High performance image signal acquisition, primary image processing, and data interface management

2、 Main functions and features

Function Description

Image signal acquisition is connected to optical sensors such as CCD and CMOS to capture high-resolution image signals in real time

Image preprocessing includes noise filtering, gain adjustment, image enhancement, etc., to improve image quality

High speed data transmission transmits image data to the main processing unit through high-speed buses (such as PCIe, dedicated high-speed interfaces)

Synchronize control with scanning platforms, laser sources, and other equipment to ensure accurate image acquisition timing

Multi channel support supports multiple image signal inputs, enabling multi-sensor collaborative acquisition

Stable and reliable industrial grade design, suitable for high-frequency operation requirements in complex semiconductor manufacturing environments

3、 Application Fields

Surface defect detection of wafers

Collect high-resolution surface images for defect recognition, localization, and classification.

Automatic Optical Inspection (AOI) System

Realize fast and high-quality image acquisition, support high-speed online detection.

Optical measurement equipment

Provide imaging data foundation, assist in morphology analysis, thickness measurement and other functions.

Electron Beam (e-beam) Imaging System

In electron beam detection equipment, it is used to collect secondary electron images or other signals.

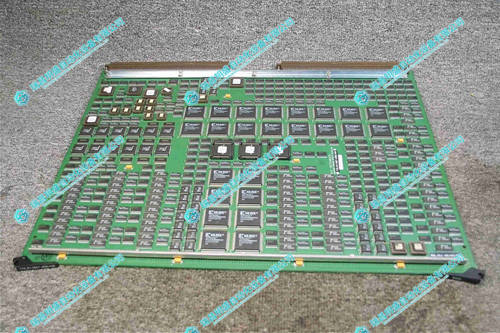

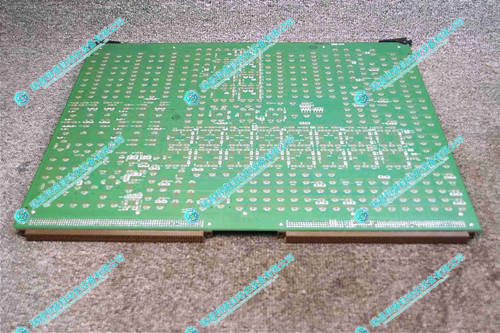

2.产 品 展 示

3.其他产品

ABSOLUTE PROCESS API4380GD隔离变送器

4.其他英文产品

AMAT 0190-11415 Digital Input Module

ASEA 2668 184-447 Communication Module

RADISYS EXM-HDEXM-MX Memory Module

| SR3624-4308-7-48C | AMAT 0100-09042 | PFEA 113-20 |

| SR3624-1032-84-7-56HC-CU | AMAT 0100-76303 | 48980001-PC DSSR170 ABB |

| SR3624-1032-7-56BC-CU | AMAT 0100-35212 | 57120001-ET DSTA180 ABB |

| SR3616-8290-7-56C | AMAT 0100-71172 | PFEA 111-65 |

| SR3616-8290-7-56BC-CU | AMAT 0100-09035 | PFEA 113-65.3PXC |

| SR3616-4381-7 | AMAT 0100-20322 | PFCL201CE 3BSX646434-108 |

| SR3616-3982-7-48C | AMAT 0100-20152 | 57360001-KM/1 DSMD122 ABB |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218