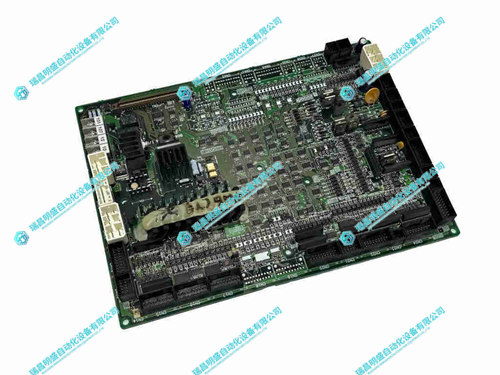

TOYOTA J9201-21002喷气编织机主板

1.产 品 资 料 介 绍:

The TOYOTA J9201-21002 motherboard, as the core control circuit component of the jet weaving machine, is like the "nerve center" of the weaving machine, responsible for multiple key tasks. It not only needs to process input and output signals, perform logical operations in weaving processes, but also coordinate the operation of execution mechanisms and achieve smooth communication with peripheral control modules. It is precisely with its precise control that the air-jet loom can achieve high-speed, high-precision, and stable weaving processes.

This motherboard has many outstanding features in terms of performance.

In terms of reliability, it is built with industrial grade electronic components and has strong anti-interference capabilities. Even in high-speed operation and complex working environments, it can always maintain stable operation. At the same time, it has overcurrent and overvoltage protection mechanisms, which greatly reduce the possibility of loom shutdown due to electrical faults and provide strong guarantees for production continuity.

In terms of signal processing capability, it performs exceptionally well. Can support input and output control of multiple channels such as nozzles, solenoid valves, color selectors, etc. Moreover, its high-speed sampling circuit can ensure accurate timing of weft yarn spraying, effectively improving the quality of weaving.

Modular structure is another major feature of it. The motherboard, sensor board, and driver board are independent of each other, making maintenance and upgrade work more convenient. In addition, it is equipped with expansion interfaces to meet the configuration requirements of different specifications of air-jet looms.

In terms of energy efficiency management, this motherboard has also been optimized. It can allocate power and control signals reasonably, thereby reducing energy consumption. The built-in power regulator circuit ensures that the system can still operate stably even when there are voltage fluctuations.

The support for intelligent functions also adds a lot of color to it. It can communicate data with the weaving machine monitoring system, support monitoring of operating parameters and fault diagnosis. The built-in self-test function can quickly locate circuit abnormalities during startup, reducing the downtime of the loom.

From the perspective of application value, the TOYOTA J9201-21002 motherboard can significantly improve the operational stability and weaving accuracy of jet looms, supporting continuous operation of looms in high-speed production environments. At the same time, it also helps to reduce maintenance costs and extend the service life of the entire machine.

2.产 品 展 示

3.其他产品

4.其他英文产品

ASEA DSCA121 Robot Control Board

KOLLMORGEN CP310250 servo driver

| AMAT 0100-71222 | AMAT 0190-09372 | AMAT 0190-19840 |

| AMAT 0100-01996 | AMAT 0190-09378 | AMAT 0190-19919 |

| AMAT 0100-96650 | AMAT 0190-09398 | AMAT 0190-19967 |

| AMAT 0100-00008 | AMAT 0190-09399 | AMAT 0190-19974 |

| AMAT 0100-70933 | AMAT 0190-09401-USE<wbr>D | AMAT 0190-19977 |

| AMAT 0100-20004 | AMAT 0190-09427 | AMAT 0190-20004 |

Contact: +86 15270269218