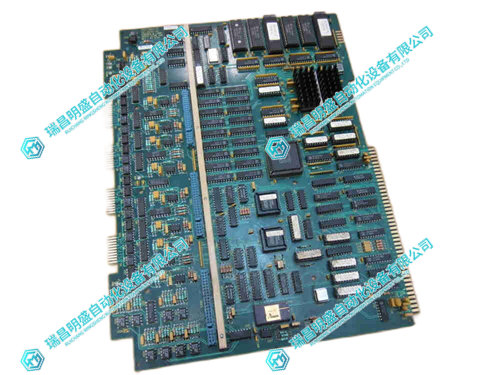

GIDDINGS & LEWIS 502-03653-01伺服控制板

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS 502-03653-01 伺服控制板详解

高精度控制:从 “达标” 到 “极致” 的突破

快速响应:应对复杂工况的 “神经中枢”

模块化设计:适配多样化场景的 “变形金刚”

可靠性保障:工业环境中的 “耐用战士”

英文资料:

GIDINGS&LEWIS 502-03653-01 servo control board detailed explanation

As a key component in the field of industrial automation and CNC machine tools, the core value of this servo control board lies in providing stable and efficient power output for equipment through precise control of servo motors. Its various characteristics form a closely coordinated system advantage in practical applications:

High precision control: a breakthrough from "standard" to "ultimate"

The closed-loop feedback system is not simply a signal transmission, but rather a real-time data acquisition of thousands of times per second through an encoder/parser, and millisecond level comparison and calibration with preset parameters. For example, in precision boring machine machining, it can control the cylindricity error of shaft parts within 0.002mm. This accuracy means that precision parts that require multiple rework in traditional machining can achieve one-time qualification, directly improving production efficiency by more than 30%.

Quick response: the "nerve center" for dealing with complex working conditions

The operating frequency of the internal 32-bit high-speed processor reaches 100MHz. When the CNC machine suddenly encounters material hardness fluctuations (such as switching from cast iron to high carbon steel), the torque output can be adjusted within 10 milliseconds to avoid tool cracking or workpiece scrap. In the grasping process of the assembly line robot, even if there is an instantaneous change of ± 5% in the conveyor belt speed, the grasping position deviation can be guaranteed not to exceed 0.5mm.

Modular design: Transformers adapted to diverse scenarios

Its standardized interface is compatible with the entire range of Giddings&Lewis control boards and supports third-party I/O module expansion. In the production line of automobile engine cylinder blocks, by matching different numbers of control boards, it is possible to quickly upgrade from 4-axis machining centers to 8-axis linkage systems, reducing the transformation cycle by 50% compared to traditional non modular solutions, and maintaining 100% system compatibility after the upgrade.

Reliability assurance: the 'durable warrior' in industrial environments

Using wide temperature components ranging from -40 ℃ to 85 ℃, it can still operate stably after 1000 hours of vibration testing (frequency 10-2000Hz). In the control system of the steel mill, even if there is strong electromagnetic interference (electric field strength up to 100V/m) around, the signal transmission error rate can be maintained below 0.001%; The built-in overload protection circuit can withstand an instantaneous impact of three times the rated current of the motor, effectively avoiding system paralysis caused by sudden loads.

2.产 品 展 示

3.其他产品

Bachmann IPC1412 FRE CM1G1 1G CF8G XPE通信处理器

4.其他英文产品

AMAT 0190-11415 Digital Input Module

ABB XVC768117 Field Input/Output Module

| PMB31D-10201-02 | PMKHRMRLY12S01 | M21NRFC-LSS-HD-02 |

| PMB31D-10201-01 | TC530 | LT 9673a |

| PMB31D-10201-00 | 07BE60R1 | HEIE 210050 R1 |

| PMB31D-10200-03 | AMAT 0240-31854 | P21NSXC-LNN-NS-03 |

| PMB31D-10200-02 | IMSET01 | M21NRXC-LNN-NS-00 |

| PMB31D-10200-01 | NKTU010 | M21NRXB-LNN-NS-00 |

| PMB31D-10200-00 | IMMFC05 | P21NSXC-LNS-NS-02 |

Contact: +86 15270269218