SANYO DENKI Q1AA13300DXS00主轴电机

1.产 品 资 料 介 绍:

- 重型数控车床主轴驱动:SANYO DENKI Q1AA13300DXS00 凭借高扭矩输出,适配直径 500mm 以上金属工件车削,保障主轴在重载切削时转速稳定,避免工件表面出现振纹,提升重型零件加工精度。

- 立式加工中心主轴控制:针对模具、机械结构件加工,该电机支持高速启停(响应时间<0.8s),适配 1000-6000rpm 可调转速,满足铣削、钻孔等多工序需求,提升加工中心综合效率。

- 大型钻攻中心主轴驱动:Q1AA13300DXS00 精准控制主轴钻孔深度与攻丝转速,适配铝合金、铸铁等材质零件批量钻攻,保障螺纹精度与孔位一致性,适配汽车零部件生产。

- 金属切削机床主轴驱动:其耐持续高负载特性,可长时间驱动主轴进行高强度切削,适配 45# 钢、不锈钢等难加工材料,减少主轴过热停机,提升机床稼动率。

- 数控铣床主轴控制:该电机通过动态平衡设计,降低主轴运行振动(振幅<0.08mm),适配复杂曲面零件铣削,保障加工表面光洁度,满足精密模具制造需求。

- 大型车床主轴驱动:Q1AA13300DXS00 支持宽转速范围(50-3000rpm),适配长轴类零件(长度>1m)车削,避免主轴高速运转时出现跳动,保障零件同轴度。

- 加工中心换刀主轴联动:SANYO DENKI Q1AA13300DXS00 配合刀库系统,精准控制主轴定位与换刀动作,换刀时间<2s,减少加工间隙,提升批量生产效率。

- 重型镗床主轴驱动:耐冲击负载特性适配大型零件镗孔加工,可承受瞬时切削冲击力,保障镗孔直径误差<0.02mm,满足工程机械箱体加工需求。

- 数控磨床主轴控制:该电机支持低速高扭矩输出,适配砂轮低速精磨工序,控制主轴转速波动<±0.1%,保障零件磨削尺寸精度,适配轴承、轴类零件精密加工。

- 大型龙门铣床主轴驱动:Q1AA13300DXS00 适配跨度 3m 以上龙门铣床,驱动主轴进行大台面零件铣削,通过刚性连接减少主轴挠度,保障大面积加工平面度。

- 数控钻床主轴驱动:针对多孔零件(如法兰盘)批量钻孔,该电机快速切换钻孔转速,适配不同孔径加工,减少刀具磨损,提升钻孔效率与合格率。

- 重型切削机床主轴控制:SANYO DENKI Q1AA13300DXS00 通过过热保护设计,适配连续 8 小时以上重型切削,避免主轴因高温损坏,保障大型机械零件稳定加工。

SANYO DENKI Q1AA13300DXS00主轴电机 英文资料:

Heavy duty CNC lathe spindle drive: SANYO DENKI Q1AA13300DXS00, with high torque output, is suitable for turning metal workpieces with a diameter of 500mm or more, ensuring stable spindle speed during heavy-duty cutting, avoiding vibration patterns on the workpiece surface, and improving the machining accuracy of heavy-duty parts.

Vertical machining center spindle control: For the processing of molds and mechanical structural components, this motor supports high-speed start stop (response time<0.8s), adapts to adjustable speeds of 1000-6000rpm, meets the needs of multiple processes such as milling and drilling, and improves the overall efficiency of the machining center.

Large drilling and tapping center spindle drive: Q1AA13300DXS00 precisely controls the spindle drilling depth and tapping speed, adapts to batch drilling and tapping of parts made of aluminum alloy, cast iron and other materials, ensures thread accuracy and hole consistency, and is suitable for automotive parts production.

Metal cutting machine tool spindle drive: It has the ability to withstand sustained high loads and can drive the spindle for high-intensity cutting for a long time. It is suitable for difficult to machine materials such as 45 # steel and stainless steel, reducing spindle overheating and downtime, and improving machine tool utilization.

CNC milling machine spindle control: This motor is designed with dynamic balance to reduce spindle vibration (amplitude<0.08mm), adapt to milling complex curved parts, ensure surface smoothness, and meet the requirements of precision mold manufacturing.

Large lathe spindle drive: Q1AA13300DXS00 supports a wide speed range (50-3000rpm) and is suitable for turning long axis parts (length>1m) to avoid jumping during high-speed operation of the spindle and ensure the coaxiality of the parts.

Machining center tool change spindle linkage: SANYO DENKI Q1AA13300DXS00, in conjunction with the tool magazine system, accurately controls spindle positioning and tool change actions, with tool change time less than 2s, reducing machining gaps and improving batch production efficiency.

Heavy duty boring machine spindle drive: with impact load resistance characteristics, it is suitable for boring large parts and can withstand instantaneous cutting impact force, ensuring that the boring diameter error is less than 0.02mm, meeting the processing requirements of engineering machinery box bodies.

CNC grinding machine spindle control: This motor supports low-speed high torque output and is suitable for low-speed precision grinding processes of grinding wheels. It controls the spindle speed fluctuation to be less than ± 0.1%, ensuring the dimensional accuracy of parts grinding and adapting to precision machining of bearings and shaft parts.

Large gantry milling machine spindle drive: Q1AA13300DXS00 is suitable for gantry milling machines with a span of more than 3m. It drives the spindle to mill large table parts and reduces spindle deflection through rigid connections, ensuring large-area machining flatness.

CNC drilling machine spindle drive: For batch drilling of porous parts (such as flanges), this motor quickly switches the drilling speed, adapts to different aperture machining, reduces tool wear, and improves drilling efficiency and qualification rate.

Heavy duty cutting machine spindle control: SANYO DENKI Q1AA13300DXS00 is designed with overheating protection to adapt to continuous heavy cutting for more than 8 hours, avoiding spindle damage due to high temperature and ensuring stable processing of large mechanical parts.

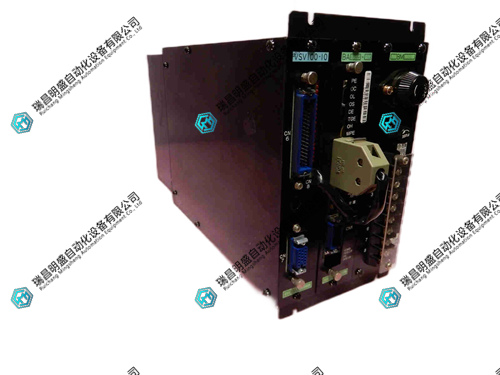

SANYO DENKI Q1AA13300DXS00主轴电机 产品展示

产品视频

3.其他产品

Honeywell CC-PDOB01 输入输出模块

PILZ 301120 输入输出系统模块

D1063S 称重传感器

4.其他英文产品

GEA 0005-4050-430 Digital Control Panel

Alfa Laval EPC50 3183045486 OP Front End Plate

ALFA LAVAL EPC50 3183062451 OP board

| IS220PPRAH1A IS220PPRAS18 | P8101Z22210020 | IMAS011 |

| IS220PHIRAH1A IS220PHRAH1B | SR10200-000000 | BRC300 |

| IS220PDOAH1A IS220PDOAH1B | PSR45A-112 | INICT03A |

| IS220PDIOH1A IS220PDIOH1B | SR10000-000000 | IMFEC12 |

| IS220PDIIH1A IS220PDIIH1B | SR06200-26404A | IEPMU01 |

| IS220PDIAH1A IS220PDIAH1B | SSS420SS400-10082/Receiver-10002 | IMCIS02 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218