1.产 品 资 料 介 绍:

620-0048作为工业级高精度数据收集模块,具备多协议兼容、毫秒级采集、抗电磁干扰及数据加密传输优势,可实现电气参数、设备状态等多维度数据的实时采集与上传,是工业数字化的核心感知部件,具体应用领域如下:

1. 钢铁冶炼车间:采集炼钢炉温度、轧辊压力等核心参数,对接DCS系统,为工艺优化提供实时数据支撑。

2. 铝加工深井铸造:监测铝液温度、冷却系统压力,及时预警漏铝风险,满足高危场景安全管控需求。

3. 工厂配电系统:实时采集回路电压、电流及功率因数,联动SCADA系统实现故障秒级报警与定位。

4. 新能源并网站:监测光伏/风电逆变器输出参数,保障并网电能质量符合电网标准,平抑功率波动。

5. 电机设备运维:采集电机运行电流谐波、功率变化,诊断转子断条、轴承磨损等隐性故障。

6. 智能配电柜改造:集成于配电柜内,远程上传多路电气参数,替代人工巡检实现数字化运维。

7. 化工反应车间:采集反应釜温度、介质浓度数据,支持本地缓存与断点续传,规避断网数据丢失。

8. 数据中心机房:监测配电回路能耗、温湿度参数,为能耗优化与设备安全运行提供数据支撑。

9. 轨道交通供电:采集列车牵引系统电气参数,耐受振动干扰,保障供电链路稳定监测。

10. 工业生产线能耗管控:分设备、分工序采集能耗数据,助力企业识别高耗能环节并优化。

11. 实验室检测:适配PCI总线架构,构建波形分析与数据处理系统,满足高精度检测需求。

12. 商业建筑配电:监测商户末端回路用电状态,预警过载、漏电风险,预防电气火灾。

13. 矿山开采设备:在多尘、高振动环境下采集采掘设备运行参数,支撑远程运维与故障预警。

14. 储能电站:采集储能单元充放电电压、电流数据,联动控制系统实现充放电策略动态调整。

15. 食品加工车间:采集杀菌设备温度、运行时长数据,实现生产过程全链路数据追溯。

该模块凭借高精度采集、强环境适配及多系统兼容能力,打通工业数据感知链路,为企业数字化转型、安全管控与降本增效赋能。

620-0048数据收集模块 英文资料:

As an industrial grade high-precision data collection module, 620-0048 has the advantages of multi protocol compatibility, millisecond level collection, anti electromagnetic interference, and data encryption transmission. It can achieve real-time collection and upload of multidimensional data such as electrical parameters and equipment status. It is the core sensing component of industrial digitization, and its specific application areas are as follows:

1. Steel smelting workshop: Collect core parameters such as steelmaking furnace temperature and roll pressure, connect with DCS system, and provide real-time data support for process optimization.

2. Aluminum processing and deep well casting: Monitor the temperature of the aluminum liquid and the pressure of the cooling system, timely warn of the risk of aluminum leakage, and meet the safety control requirements of high-risk scenarios.

3. Factory power distribution system: Real time collection of circuit voltage, current, and power factor, linked with SCADA system to achieve fault second level alarm and positioning.

4. New energy integration website: Monitor the output parameters of photovoltaic/wind power inverters, ensure that the quality of grid connected electricity meets grid standards, and smooth out power fluctuations.

5. Motor equipment maintenance: Collect motor operating current harmonics and power changes, diagnose hidden faults such as rotor bar breakage and bearing wear.

6. Intelligent distribution cabinet renovation: integrated into the distribution cabinet, remotely uploading multiple electrical parameters, replacing manual inspection to achieve digital operation and maintenance.

7. Chemical reaction workshop: Collect reaction kettle temperature and medium concentration data, support local caching and breakpoint retransmission, and avoid data loss due to network disconnection.

8. Data center computer room: Monitor the energy consumption, temperature and humidity parameters of the power distribution circuit, and provide data support for energy consumption optimization and equipment safety operation.

9. Rail transit power supply: Collect electrical parameters of the train traction system, withstand vibration interference, and ensure stable monitoring of the power supply link.

10. Energy consumption control of industrial production lines: Collect energy consumption data by equipment and process to help enterprises identify high energy consuming links and optimize them.

11. Laboratory testing: Adapt to PCI bus architecture, build waveform analysis and data processing system to meet high-precision testing requirements.

12. Commercial building power distribution: Monitor the electrical status of the merchant's terminal circuit, warn of overload and leakage risks, and prevent electrical fires.

13. Mining equipment: Collect operating parameters of mining equipment in dusty and high vibration environments, support remote operation and maintenance, and provide fault warning.

14. Energy storage power station: Collect charging and discharging voltage and current data of energy storage units, and link the control system to dynamically adjust the charging and discharging strategy.

15. Food processing workshop: Collect temperature and operating time data of sterilization equipment to achieve full traceability of production process data.

This module, with its high-precision acquisition, strong environmental adaptation, and multi system compatibility capabilities, connects the industrial data perception link and empowers enterprises with digital transformation, security control, and cost reduction and efficiency improvement.

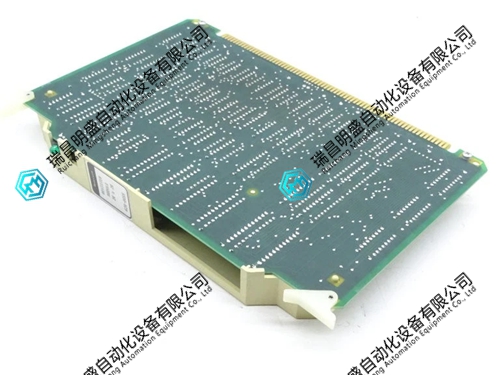

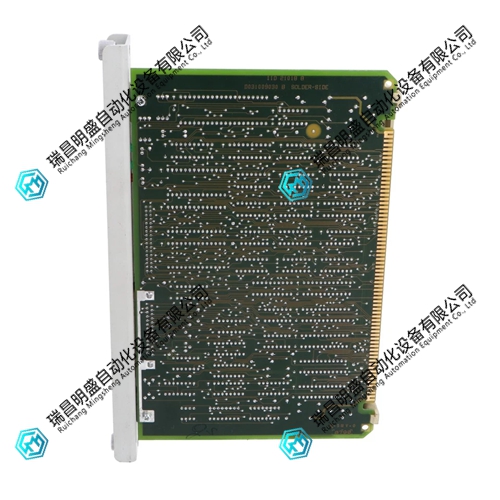

620-0048数据收集模块 产品展示

产品视频

3.其他产品

FOXBORO FBM216B P0927AJ通信接口模块

MECS UTX1700PTFE绝缘材料

MOTOROLA PMC-6130-J 0100RSDPMC-J 控制板模块

4.其他英文产品

LAM 853-049542-173 servo system spare parts

AB 1756-L73S safety controller

SDCS-CON4-COAT-ROHS Programmable Processor

| 4VM82-008-4 | 3090-TB6 | UFC921A101 |

| 4VM82-000-8 | 3090-SRK-2 | IC3600SVSA1 |

| 4VM81-220-5 | 3090-SPM2000 | IC3600SVFA1B |

| 4VM62-200-7 | HP56S261Z6 | IC3600SVFA1A |

| 4N63-100-2 | HG107A6 | IC3600SVFA1 |

| 4N63-100-1 | PXSWLPRCYL2062PRNO3WDCEURO | IC3600SVDE1 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218